Sulfur electrode, and preparation and application thereof

A sulfur electrode and electrode technology, which is applied in the field of energy storage, can solve the problems that cannot fully meet the requirements of Li-S batteries, and achieve the effects of improving electrochemical performance, increasing electrode reaction rate, and increasing specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

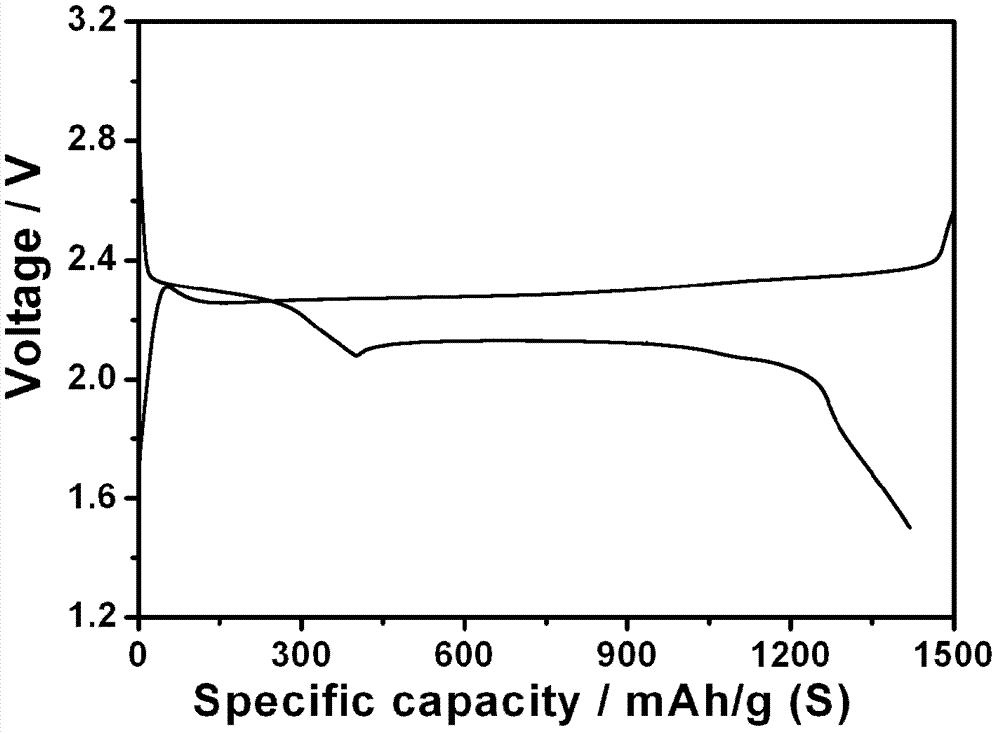

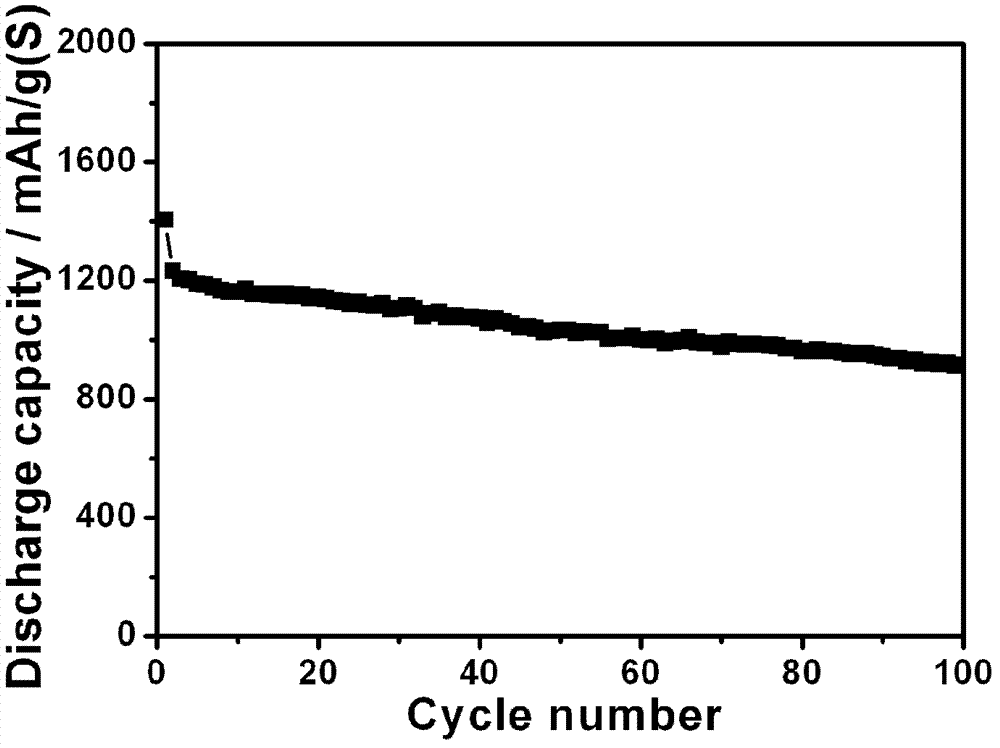

Embodiment 1

[0061] (1) Preparation of sulfur / carbon composite material: Weigh 0.1g of self-made porous carbon, the specific surface area of the carbon material is 1382m 2 / g, the pore volume is 2.2cm 3 / g, wherein the volume ratio of micropores to mesopores is: 1:1.28, and 1.0 g of elemental sulfur is put into an agate mortar and mixed evenly, transferred to a ball mill jar for ball milling for 2 hours, the ball-to-material ratio is 1:0.15, and the milling speed is 300r. / min. Heat the obtained mixture in a tube furnace to obtain the prepared sulfur / carbon composite material. The heating program was as follows: the temperature was raised from room temperature to 130° C. and kept for 3 hours, then the temperature was raised to 260° C. and kept for 3 hours. The heating rate was 3° C. / min. The sulfur content in the final composite was 40.2 wt%.

[0062] (2) Preparation of sulfur electrode: mix sulfur / carbon composite material, AB and PTFE according to the mass ratio of 7:1.5:1.5, add 3m...

Embodiment 2

[0065] Acid-modified porous carbon materials, using the modified carbon materials to prepare sulfur / carbon composite materials, and using the composite materials to prepare positive electrodes and assemble Li-S batteries, the preparation method is as follows:

[0066] (1) Modification of carbon materials: pipette a certain mass of concentrated nitric acid (60% concentration) to make a 5% nitric acid aqueous solution; weigh 1g of porous carbon (specific surface area is 1382m 2 / g) Add 50mL of 5% nitric acid solution, stir at a constant temperature of 30°C for 4h, then wash with deionized water until neutral, dry and weigh.

[0067] (2) Preparation of sulfur / carbon composite material: Weigh 0.1g of acid-modified porous carbon material, the specific surface area of carbon material is 1237m 2 / g, pore volume 1.79cm 3 / g, wherein the volume ratio of micropores to mesopores is: 1:4.8, and 1.0 g of elemental sulfur is put into an agate mortar and mixed evenly, transferred to a ball...

Embodiment 3

[0071] Acid-modified and calcined carbon materials, using the modified carbon materials to prepare sulfur / carbon composite materials, and using the composite materials to prepare positive electrodes and assemble Li-S batteries, the preparation method is as follows:

[0072] (1) Modification of carbon materials: pipette a certain mass of concentrated nitric acid (60% concentration) to make a 5% nitric acid aqueous solution; weigh 1g of porous carbon (specific surface area is 1382m 2 / g) Add 50mL of 5% nitric acid solution, stir at a constant temperature of 30°C for 4h, then wash with deionized water until neutral, dry and weigh. The obtained carbon powder was calcined at 700° C. for 3 h under the protection of an argon atmosphere to further obtain an acid-modified and calcined carbon material.

[0073] (2) Preparation of sulfur / carbon composite material: Weigh 0.1g of acid-modified porous carbon material, the specific surface area of carbon material is 1143m 2 / g, pore volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com