Active and non-active combined core water injection heat lead-out device

A heat-exporting, passive technology, applied in cooling devices, emergency protection devices, reactors, etc., can solve problems such as the inability to fully guarantee the safety and reliability of nuclear power plants, so as to avoid excessive pressure in the primary circuit, reduce the possibility, and reduce false start accidents the effect of consequences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

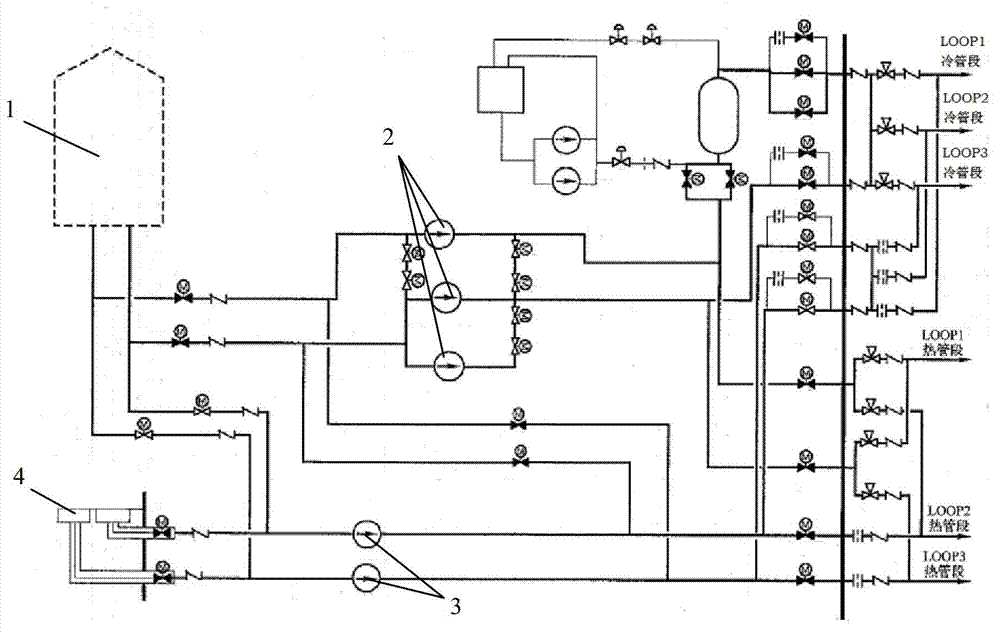

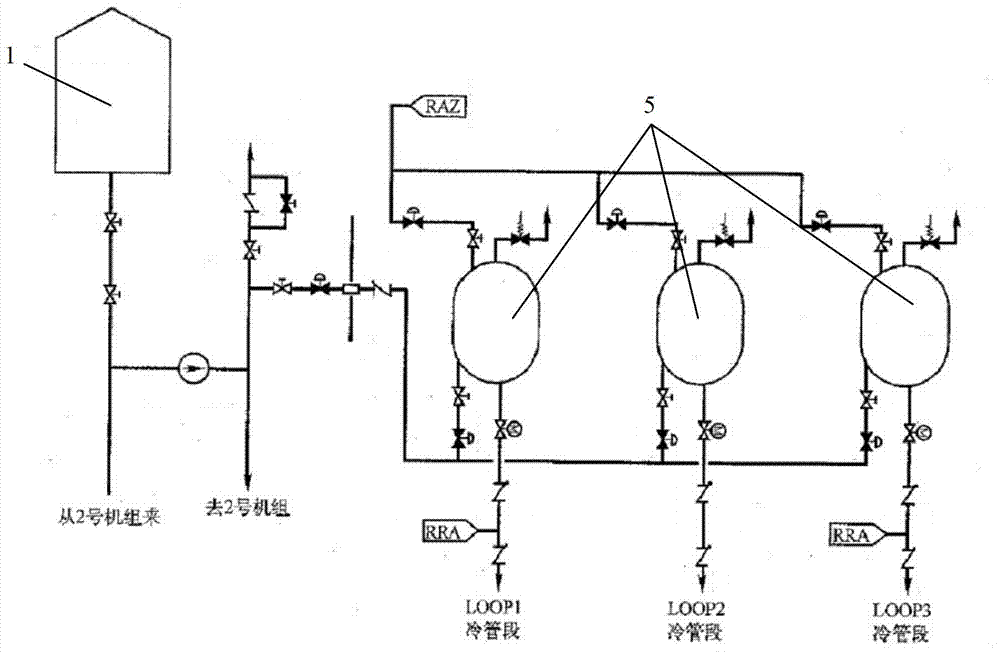

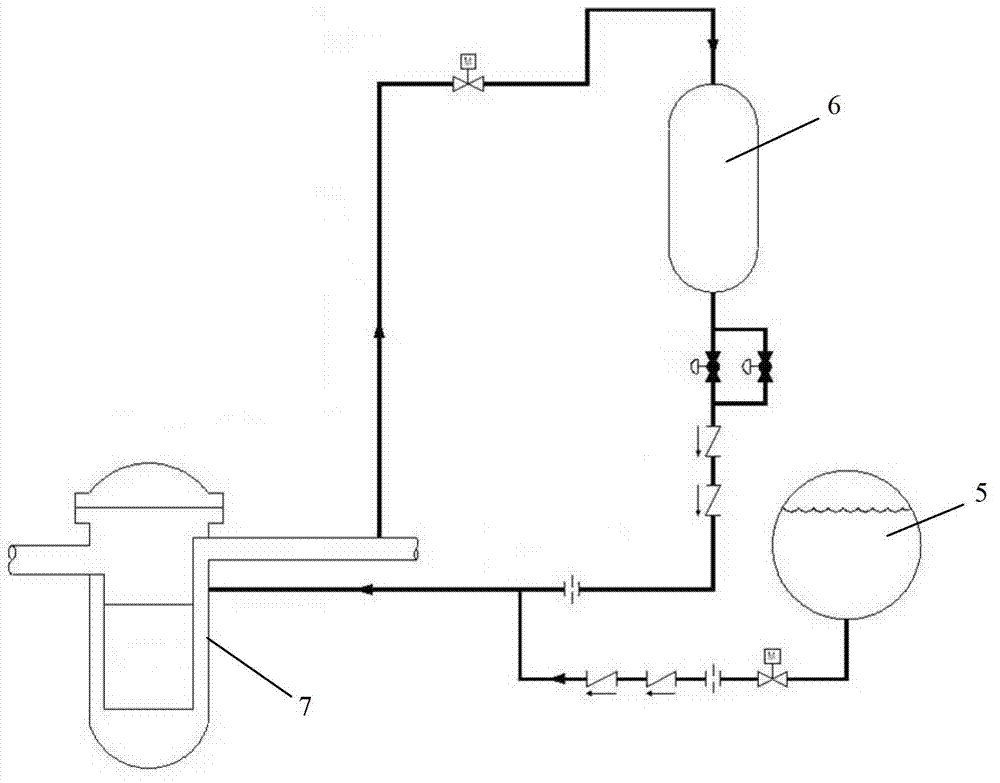

[0017] The active and passive combined core water injection heat export device provided by the present invention adopts active medium-pressure safety injection pump and low-pressure safety injection pump, passive safety injection tank and core water supply tank, and replacement inside the containment Feed water tank.

[0018] Specifically, the active part of the core water injection heat export device can be provided with two mutually independent medium-pressure safety injection pumps and two mutually independent low-pressure safety injection pumps. Both the medium-pressure safety injection pump and the low-pressure safety injection pump are connected between the built-in refueling water tank and the cold / heat pipe section of the primary circuit through pipelines equipped with control valves. The initial stage of the water injection of the safety injection pump into the primary circuit of the reactor is the cold section injection, and the simultaneous injection of the cold and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com