Method and device for detecting and debugging violin panel

A technology of panel detection and debugging method, applied in the field of musical instrument manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

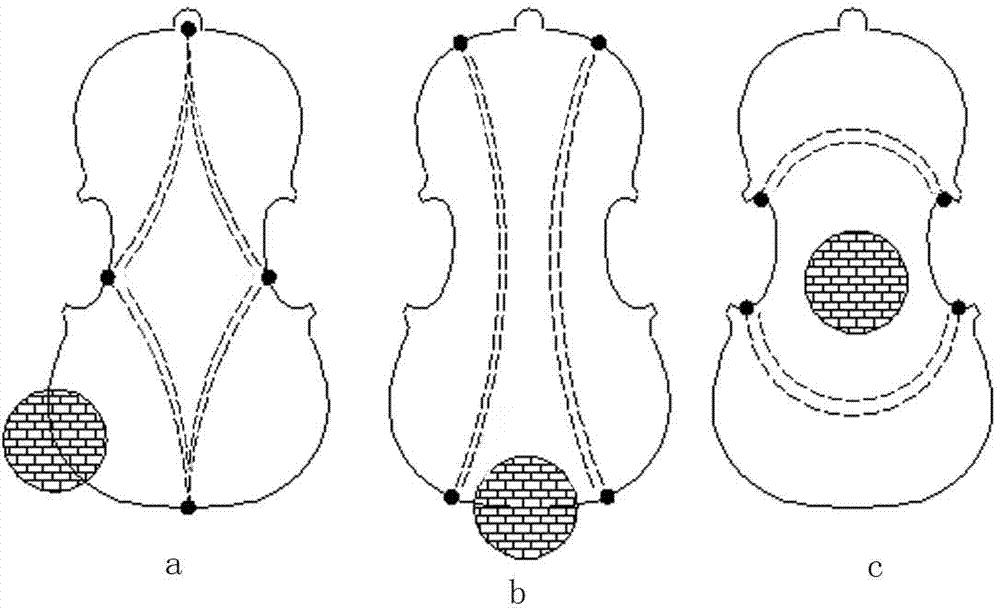

[0019] The invention provides a method for detecting and debugging a violin panel, which comprises the following steps:

[0020] (1) Place the front panel and the back panel of the violin panel in groups, place the concave surface upwards respectively, and place 80-100 mesh fine wood inspection powder in the concave surface (it is best to evenly spread one-third of the panel area).

[0021] (2) Place the front panel and the back panel sprinkled with fine wood detection powder in the first vibration area. The vibration detection method of the front panel is: first adjust the frequency to 78Hz, and then gradually increase the frequency until 95Hz to observe and record the fine wood detection Powder distribution; the back panel vibration detection method is: first adjust the frequency to 110Hz, and then gradually increase the frequency until 120Hz to observe and record the fine wood detection powder distribution.

[0022] (3) Place the front panel and back panel sprinkled with fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com