Preparation method for yttrium aluminium garnet nano-powder

A technology of yttrium aluminum garnet and nano powder, which is applied in the field of materials, can solve the problems of many control variables, complicated process, unfavorable industrial production of YAG powder, etc., and achieves lowering sintering temperature, simplifying process operation flow, and reducing process control parameters. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

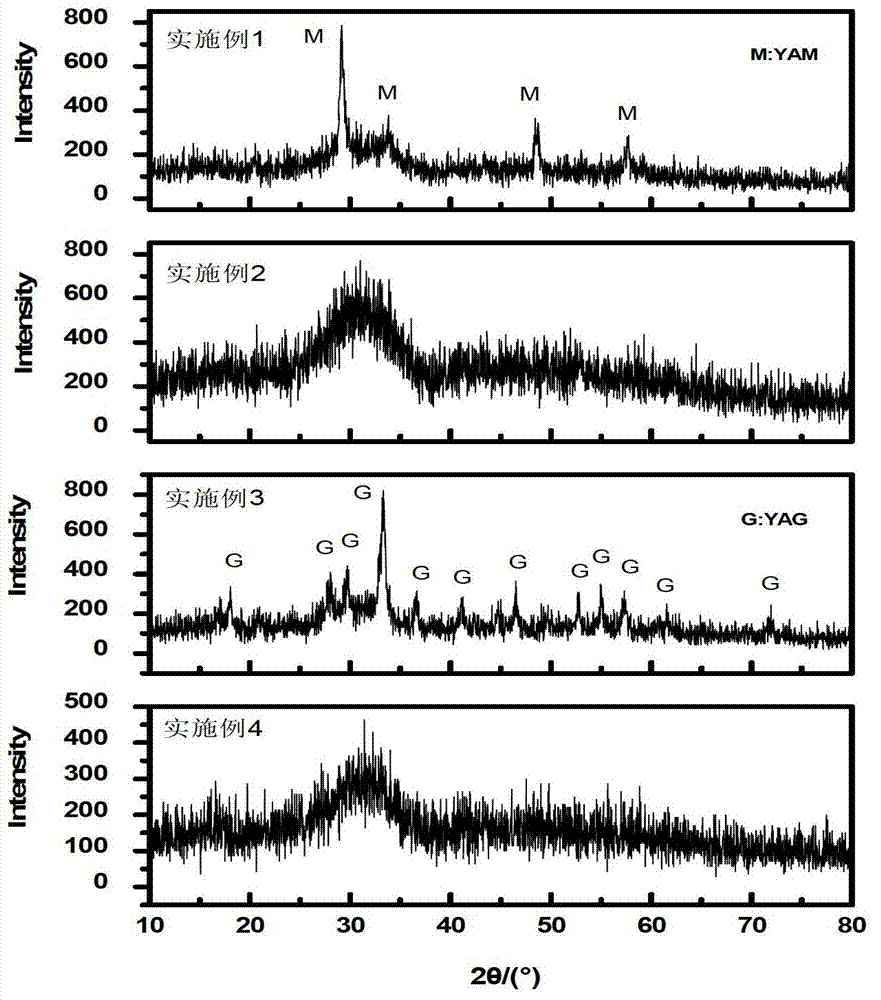

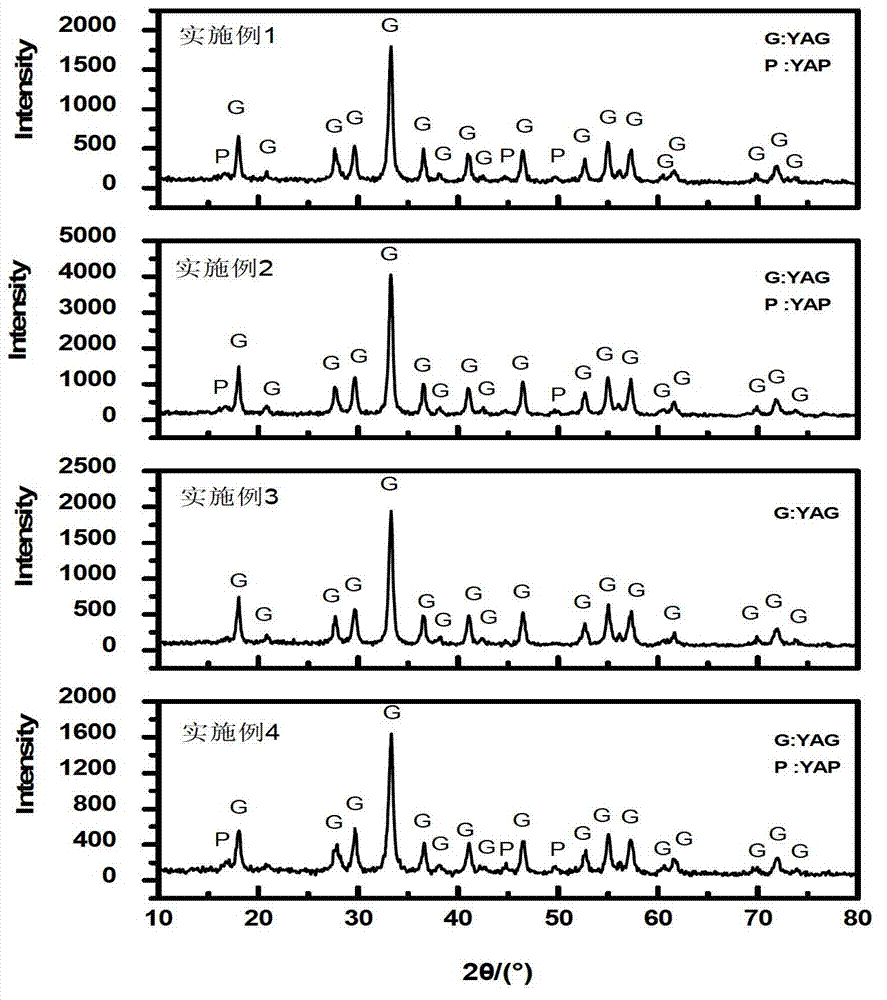

Embodiment 1

[0046] Accurately weigh a certain mass of Al(NO 3 ) 3 9H 2 O, Y (NO 3 ) 3 ·6H 2 O and NH 4 HCO 3 Prepare a solution with deionized water, the concentrations are [Y 3+ ]=0.09mol / L, [Al 3+ ]=0.15mol / L, [NH 4 HCO 3 ]=1.92mol / L; Measure 250ml Al(NO 3 ) 3 , Y(NO 3 ) 3 Mix the solution evenly, seal it, place it in an ice bath at 0°C, stir and pre-cool to a constant temperature, and keep stirring for use; measure 250ml of NH 4 HCO 3 solution, and adding dodecylbenzenesulfonic acid (C 18 h 30 SO 3 ), stir well and set aside; NH 4 HCO 3 with C 18 h 30 SO 3 Inject the homogeneous solution of the yttrium and aluminum nitrate homogeneous solution that is stirred vigorously at one time, and continue to stir vigorously in an ice bath for 4 hours after sealing, and age to form a milky white colloidal precipitation solution; continue to obtain the milky white colloidal precipitation solution Ultrasonic treatment for 1 h; vacuum filter the precipitated solution after ult...

Embodiment 2

[0048] Accurately weigh a certain mass of Al(NO 3 ) 3 9H 2 O, Y (NO 3 ) 3 ·6H 2 O and NH 4 HCO 3 Prepare a solution with deionized water, the concentrations are [Y 3+ ]=0.09mol / L, [Al 3+ ]=0.15mol / L, [NH 4 HCO 3 ]=1.92mol / L; Measure 250ml Al(NO 3 ) 3 , Y(NO 3 ) 3 solution, seal it at room temperature (about 25°C), stir and mix evenly, and keep stirring for use; measure 250ml of NH 4 HCO 3 solution, and adding dodecylbenzenesulfonic acid (C 18 h 30 SO 3 ), stir well and set aside; NH 4 HCO 3 with C 18 h 30 SO 3 The homogeneous solution is injected into the vigorously stirred yttrium and aluminum nitrate homogeneous solution at one time, after sealing, continue to vigorously stir for 4 hours, and age to form a milky white colloidal precipitation solution; continue to ultrasonicate the obtained milky white colloidal precipitation solution for 1 hour; Vacuum filter the precipitated solution after ultrasonic treatment, and rinse with deionized water and ethan...

Embodiment 3

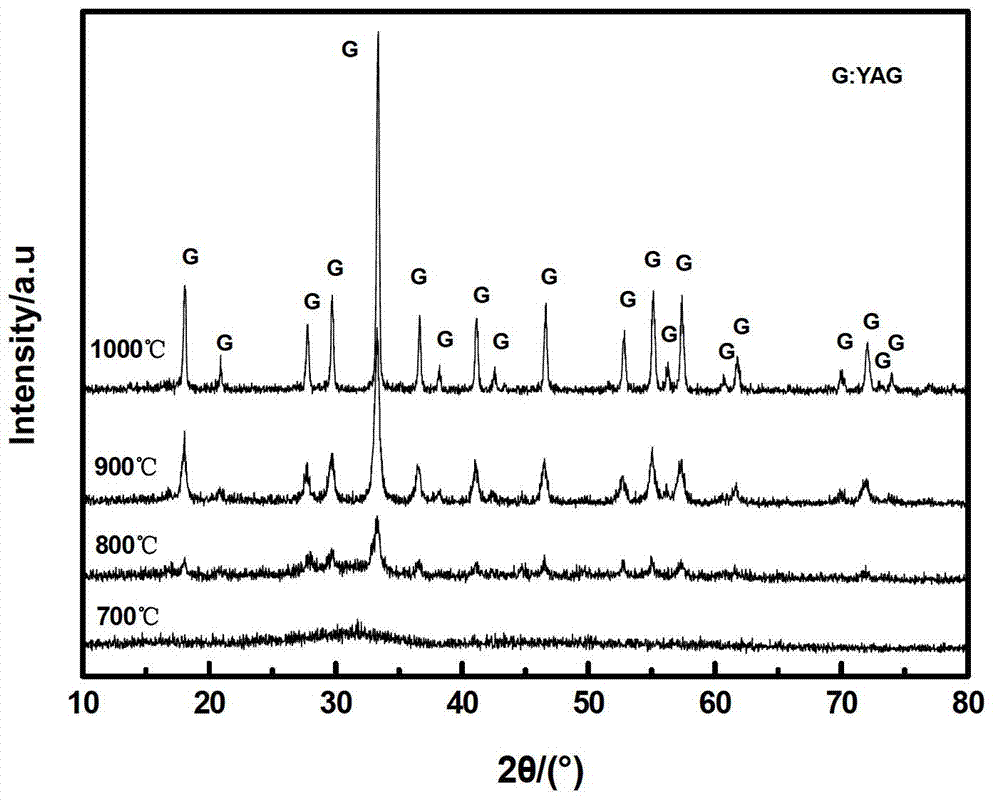

[0050] Accurately weigh a certain mass of Al(NO 3 ) 3 9H 2 O, Y (NO 3 ) 3 ·6H 2 O and NH 4 HCO 3 Prepare a solution with deionized water, the concentrations are [Y 3+ ]=0.09mol / L, [Al 3+ ]=0.15mol / L, [NH 4 HCO 3 ]=1.92mol / L; Measure 250ml Al(NO 3 ) 3 , Y(NO 3 ) 3 Mix the solution evenly, seal it, place it in a water bath at 50°C, stir and preheat to a constant temperature, and keep stirring for use; measure 250ml of NH 4 HCO 3 solution, and adding dodecylbenzenesulfonic acid (C 18 h 30 SO 3 ), stir well and set aside; NH 4 HCO 3 with C 18 h 30 SO 3 Inject the homogeneous solution of yttrium and aluminum nitrate that is stirred vigorously into the homogeneous solution of nitrate of yttrium and aluminum at one time, and continue to stir vigorously in the water bath for 4 hours after sealing, and age to form a milky white colloidal precipitation solution; continue to ultrasonicate the obtained milky white colloidal precipitation solution Treat for 1 h; vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com