Triple-silver low-emissivity coated glass and preparation method thereof

A low-emissivity coating and manufacturing method technology, applied in the field of glass, can solve the problems of low visible light transmittance, appearance color interference color, limited color selection, etc., achieve high visible light transmittance, diversify color selection, and avoid interference color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

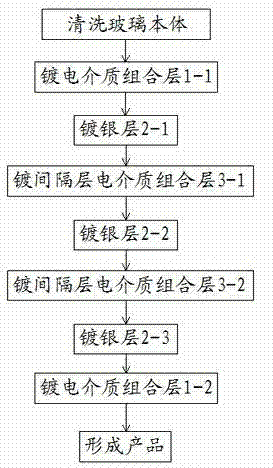

Image

Examples

Embodiment 1

[0048] The specific implementation of the present invention uses a magnetron sputtering coating machine, including 23 alternating current rotating double cathodes and 8 direct current plane cathodes, adopting the process parameters listed in the following table, using 14 alternating current rotating double cathodes and 3 direct current plane cathodes, Three silver low-emissivity coated glass of the present invention, its process parameter and the position list of target are as follows:

[0049] Three-silver low-emissivity coated glass target position and process parameters

[0050]

[0051] All Silicon Nitride (Si 3 N 4 ) The film layer uses a silicon-aluminum (92:8) target, and is sputtered and deposited in an argon and nitrogen atmosphere by means of AC double-rotating cathodes and intermediate-frequency reactive magnetron sputtering, with a power of 20-110kw and a frequency of 20-40kHz;

[0052] All silicon oxynitride (SiOxNy) films in the table use silicon aluminum ...

Embodiment 2

[0078] All the other are the same as in Example 1, the difference is that the composition material, number of layers and thickness of each combined film layer, its process parameters and the position list of the target are as follows:

[0079] Three-silver low-emissivity coated glass target position and process parameters

[0080]

[0081] Niobium oxide (Nb 2 o 5 ) layer using niobium oxide target, using AC double rotating cathode, intermediate frequency reactive magnetron sputtering method in argon, oxygen atmosphere sputtering deposition, power 50-100kw, frequency 20-40kHz;

[0082] Titanium oxide (TiO 2 ) layer is made of ceramic titanium oxide target, which is sputtered and deposited in argon and oxygen atmosphere by means of AC double rotating cathode and intermediate frequency reactive magnetron sputtering, with a power of 50-100kw and a frequency of 20-40kHz;

[0083] The zinc oxide (ZnO) layer in the table uses a zinc-aluminum (98:2) target, and is sputtered an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com