Nano-calcium carbonate carbonization reaction kettle

A nano-calcium carbonate and reaction kettle technology, which is applied in the fields of calcium carbonate/strontium/barium, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of complex design of supergravity synthesizers, limited industrial applications, and high operating costs, and achieves The effect of fully dispersing and enhancing mass transfer, short reaction time and increasing gas-liquid contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

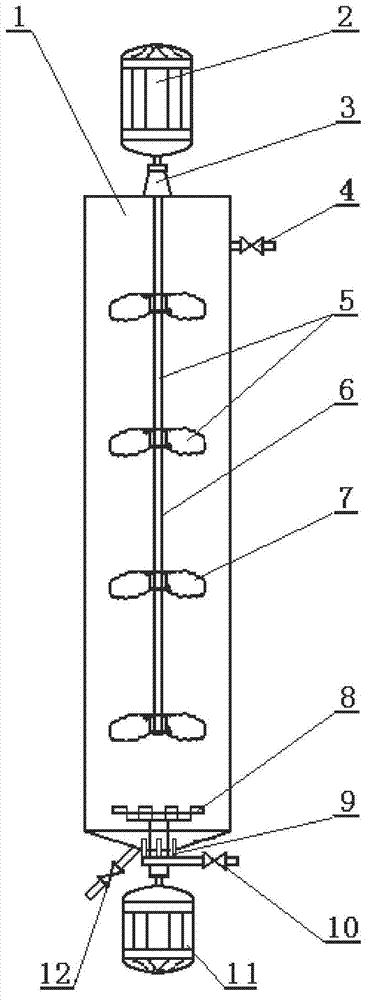

[0032] The reaction kettle adopts stainless steel structure, and the ratio of height to diameter is 3:1. The setting includes a motor, a reducer, an agitator, an air inlet pipe and a valve, and a multi-layer propulsion agitator A5 and a disc sawtooth agitator B8 are arranged on the central axis of the reactor 1, wherein a circular agitator is arranged near the bottom of the reactor 1. Disk serrated agitator B8, the diameter of agitator B8 is 700mm, the height of agitator B8 from the bottom of reactor 1 is 400mm, the height of agitator B8 from the air outlet of inlet pipe 9 is 200mm, and the speed of agitator B8 is controlled at 400r / min frequency conversion motor B11 connection. In the middle and upper part of the reaction kettle 1, a multi-layer propulsion type agitator A5 is arranged, and the agitator A5 is composed of a stirring shaft 6 and a stirring impeller 7 with 3 blades, and the blades of the stirring impeller 7 are arranged to be inclined at 10° in the same directio...

Embodiment 2

[0035] The reaction kettle adopts stainless steel structure, and the aspect ratio is 2.5:1. The setting includes a motor, a reducer, an agitator, an air inlet pipe and a valve, and a multi-layer propulsion agitator A5 and a disc sawtooth agitator B8 are arranged on the central axis of the reactor 1, wherein a circular agitator is arranged near the bottom of the reactor 1. Disk serrated agitator B8, the diameter of agitator B8 is 800mm, the height of agitator B8 from the bottom of reactor 1 is 360mm, the height of agitator B8 from the air outlet of air inlet pipe 9 is 200mm, and the speed of agitator B8 is controlled at 350r / min frequency conversion motor B11 connection. In the middle and upper part of the reaction kettle 1, a multi-layer propulsion type agitator A5 is arranged. The agitator A5 is composed of a stirring shaft 6 and a stirring impeller 7 with 2 blades and 4 blades. The blades of the stirring impeller 7 are arranged to be inclined at 15° in the same direction. ...

Embodiment 3

[0038] The reaction kettle adopts carbon steel structure, and the ratio of height to diameter is 4.5:1. The setting includes a motor, a reducer, an agitator, an air inlet pipe and a valve, and a multi-layer propulsion agitator A5 and a disc sawtooth agitator B8 are arranged on the central axis of the reactor 1, wherein a circular agitator is arranged near the bottom of the reactor 1. Disk serrated agitator B8, the diameter of agitator B8 is 400mm, the height of agitator B8 from the bottom of reactor 1 is 600mm, the height of agitator B8 from the air outlet of air inlet pipe 9 is 350mm, and the speed of agitator B8 is controlled at 450r / min frequency conversion motor B11 connection. In the middle and upper part of the reaction kettle 1, a multi-layer propulsion type agitator A5 is arranged. The agitator A5 is composed of a stirring shaft 6 and a stirring impeller 7 with 5 blades and 2 blades. The blades of the agitating impeller 7 are arranged to be inclined 8° in the same dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com