Oil cylinder luffing crane tower body and processing method thereof

A crane and tower body technology is applied to the cylinder luffing crane tower body and its processing field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

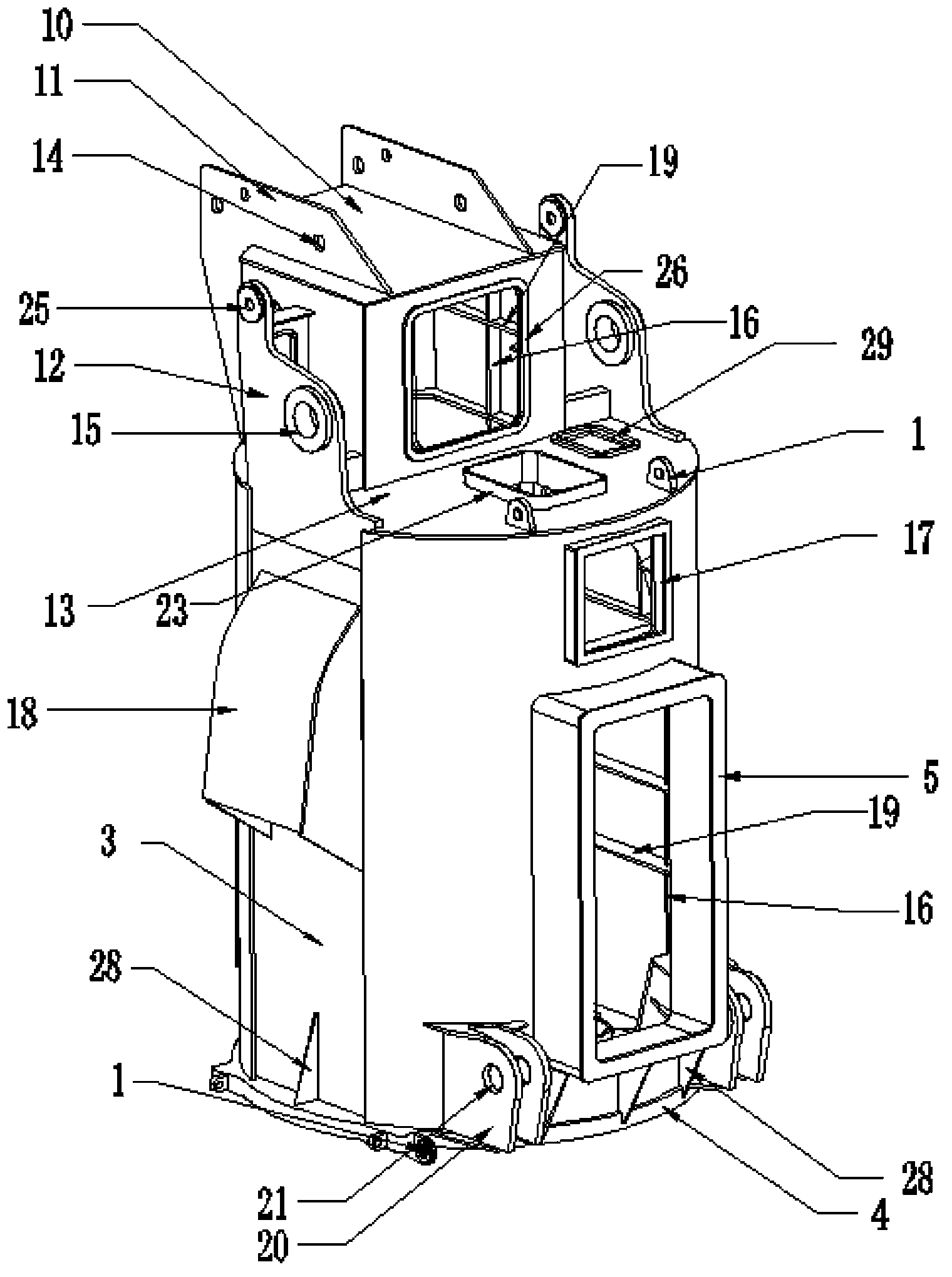

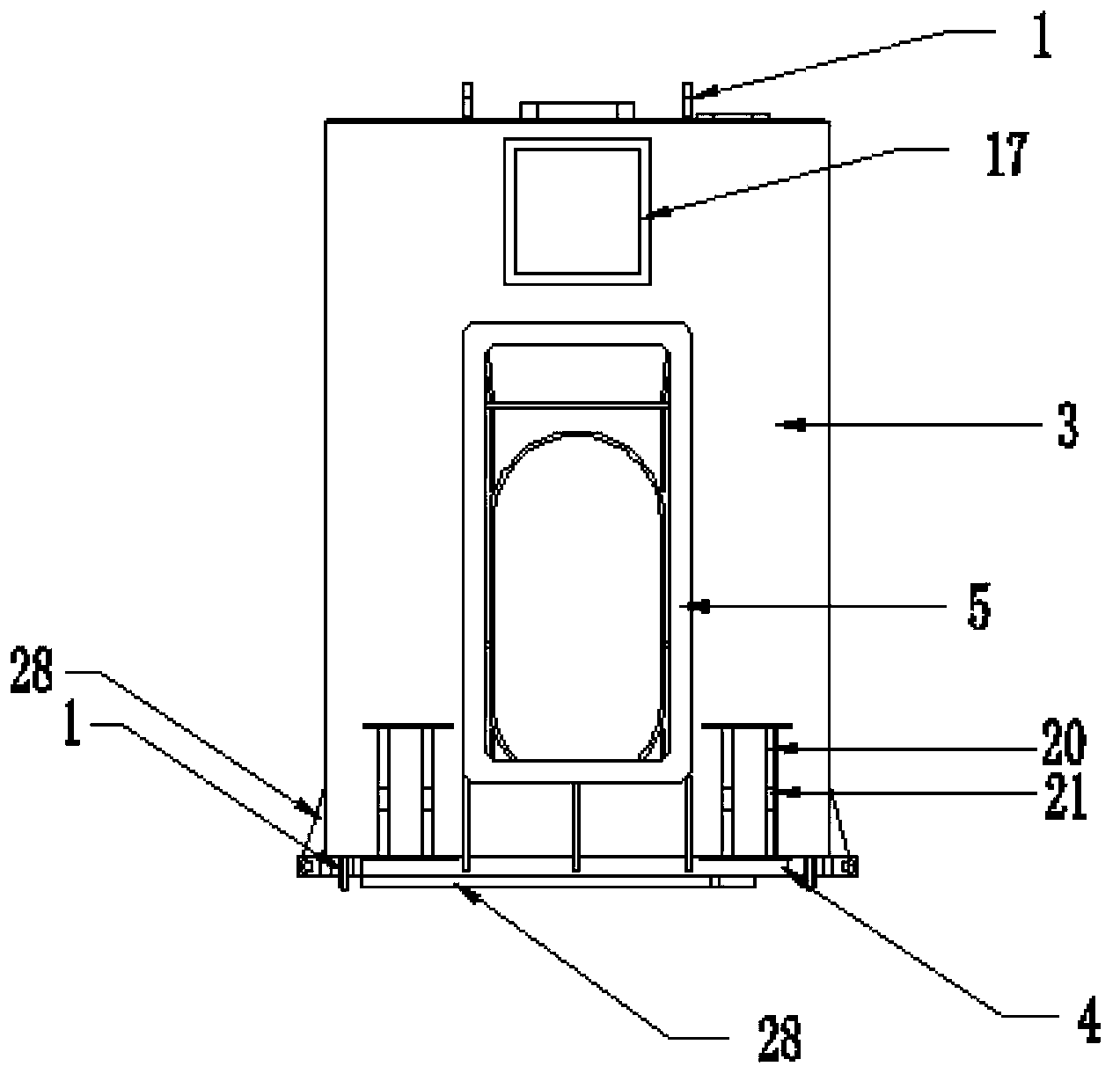

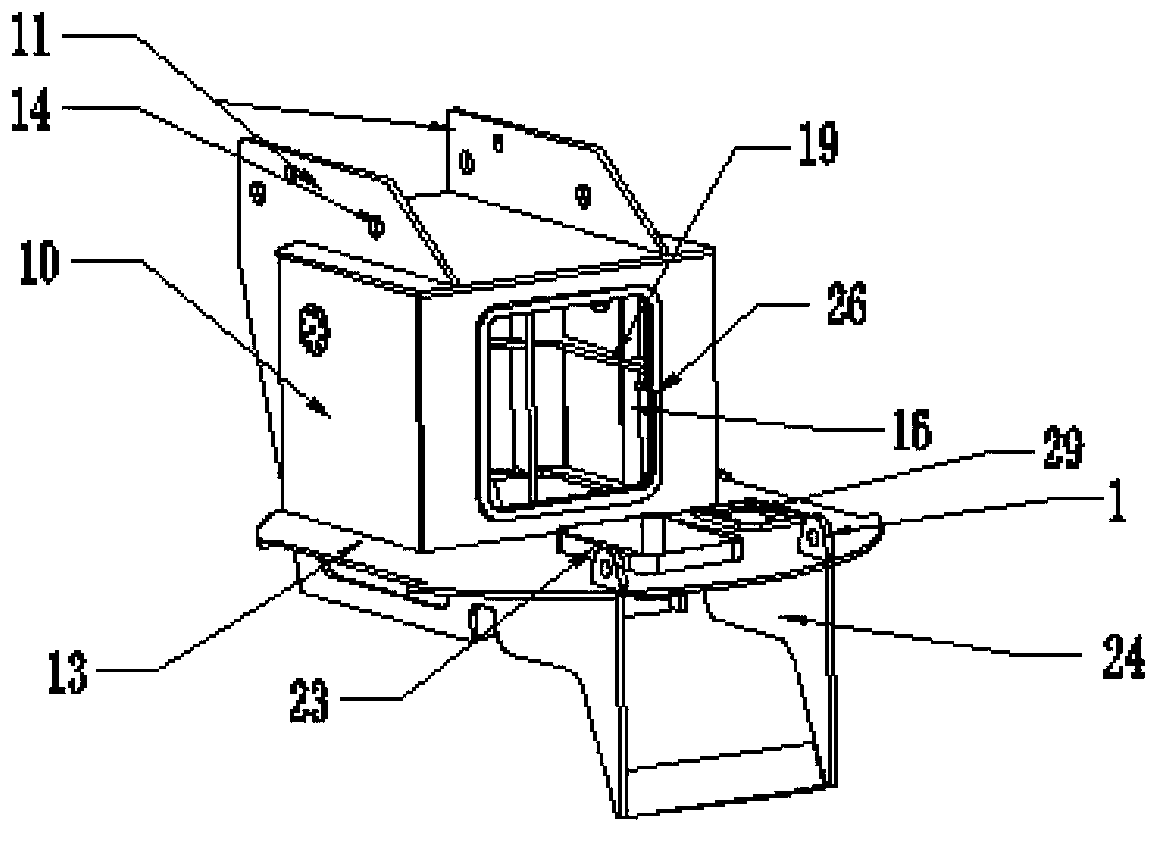

[0032] like figure 1 As shown, the embodiment of the present invention provides a cylinder luffing crane tower body, the tower body includes a tower body shell 3, one end of the tower body shell 3 is connected with a top cover 13, and the other end of the tower body shell 3 is connected with a The large base plate 4 of the tower body is provided with a driver's cab channel 5 on the tower body shell 3, such as Figure 4 As shown, the top surface of the large bottom plate of the tower body is provided with a rotary mounting surface 30 and a number of through holes, and the large bottom plate 4 of the tower body is provided with an oil cylinder mounting support 20 connected with the tower body shell 3, and the oil cylinder mounting support 20 is also connected to the tower body. The body is connected to the bottom plate 4, the cylinder mounting support 20 is provided with the cylinder mounting hinge hole 21, and the tower body also includes: the fuel tank housing 10 and the side ...

Embodiment 2

[0044] The embodiment of the present invention provides a method for processing the tower body provided in Embodiment 1, comprising the following steps:

[0045] Step a) Weld the formed fuel tank housing 10, side plates 12, top cover 12 and lifting mechanism mounting support 11 together, respectively, to obtain the following: figure 2 shown structure.

[0046] Step b) Weld the tower shell 3 and the tower base plate 4 together to obtain the following: image 3 shown structure.

[0047] Step c) Go to the machining workshop to process the large bottom plate 4 of the tower body on the boring machine, including processing the rotary mounting surface 30, through holes, threaded holes and bottom holes, wherein the through holes include weight reduction holes 8, rotary mechanism installation holes 6, The first pump unit maintenance hole 9, the cable channel 7, and the threaded holes are respectively located at: the outer edge of the slewing mechanism mounting hole 6, the outer edge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com