Non-delamination drilling method based on drilling force control for carbon fiber reinforced polymer (CFRP) laminate

A technology of reinforced composite materials and drilling methods, applied in the field of mechanical processing, can solve the problems of large dependence on original data, large influence of human factors, large errors, etc., to avoid delamination damage defects, reduce production costs, and reduce product scrapping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

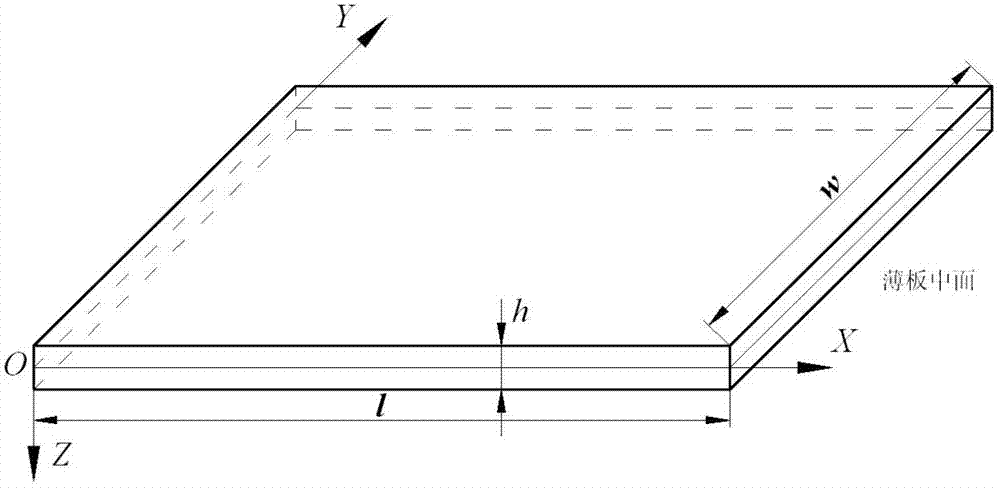

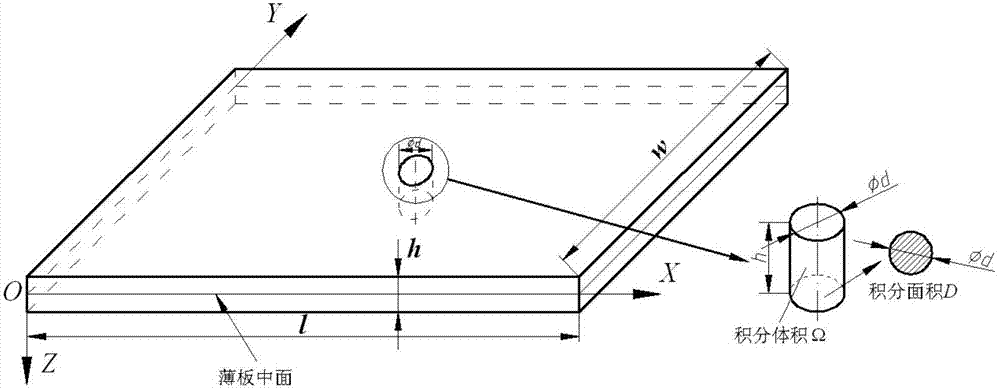

[0050] In this example, a cemented carbide twist drill with a diameter of 4.9 mm is used to drill and process T300 / 250F CFRP laminates. The determination of the critical thrust of the drilling layer includes the following steps, please refer to figure 1 , figure 2 with image 3 :

[0051] In the first step, when the drill bit is drilling the CFRP laminate, at the moment when the material is about to delaminate, the drilling axial force does work along the deflection direction of the CFRP laminate, and part of it is used to overcome the bending deformation of the CFRP laminate and convert it into The other part of the bending potential energy inside the matrix is converted into the surface energy required for the propagation of delamination cracks in the plate. When the strain energy (the difference between the work done by the drilling axial force along the deflection direction of the CFRP laminate and the bending potential energy of the CFRP laminate) is exactly equal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com