La-containing high-strength steel plate and heat treatment technology thereof

A high-strength steel plate and rare earth technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problem of less than 20 kinds of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

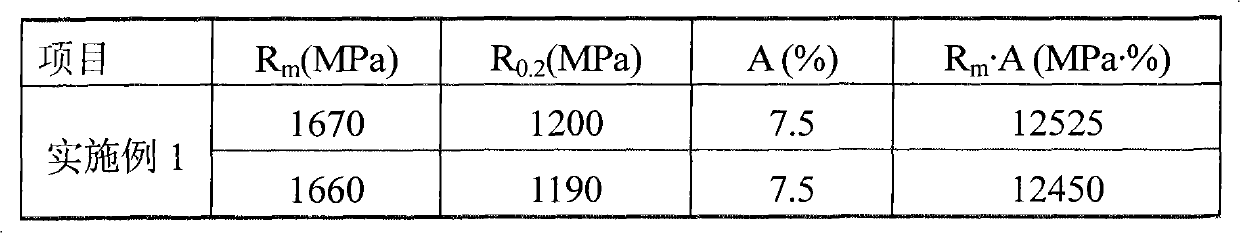

[0012] The thickness of the steel plate is 8mm, and its heat treatment process system is: austenitizing temperature 910 ℃, water quenching after holding time for 44 minutes. Sampling test, its mechanical property test value is shown in Table 1:

[0013] Table 1 Mechanical property detection value

[0014]

Embodiment 2

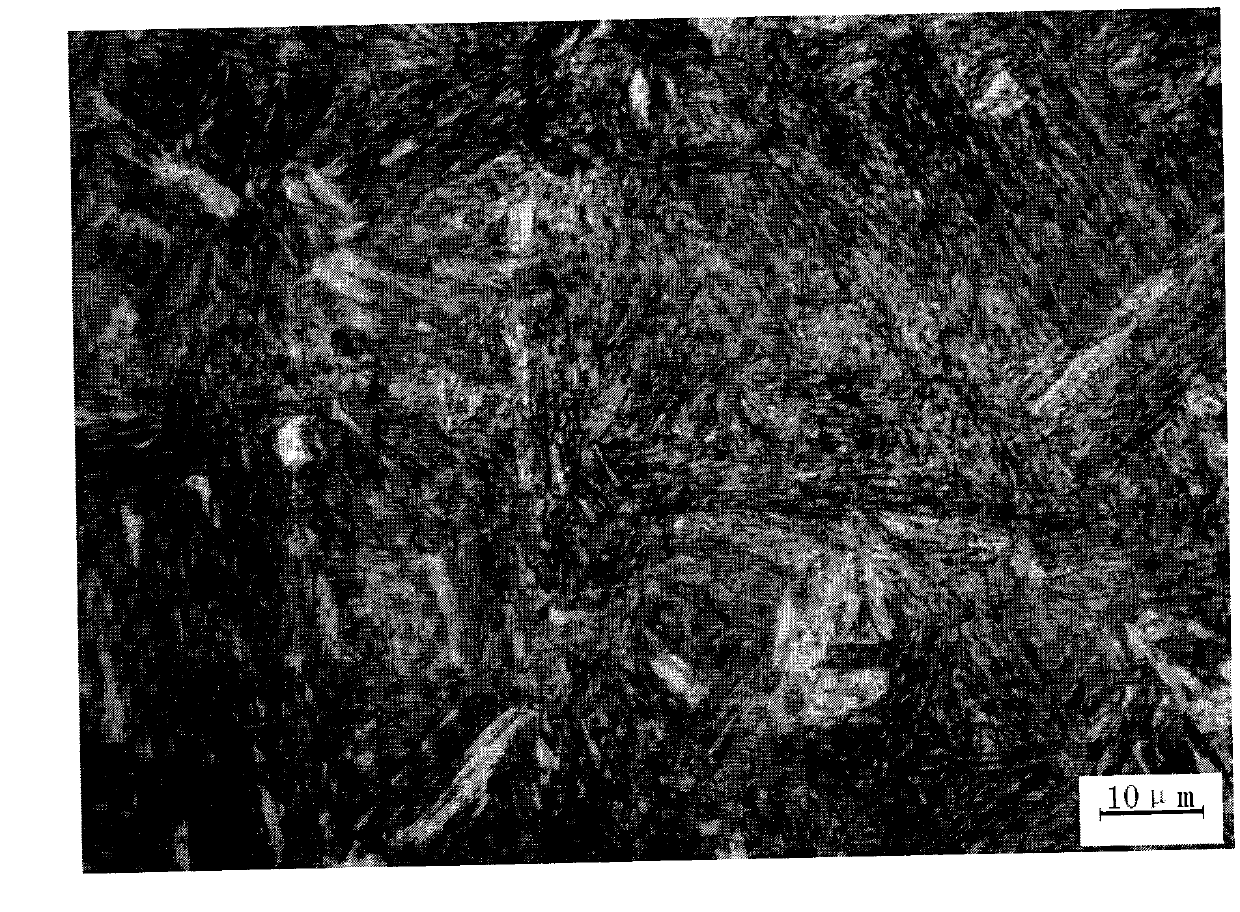

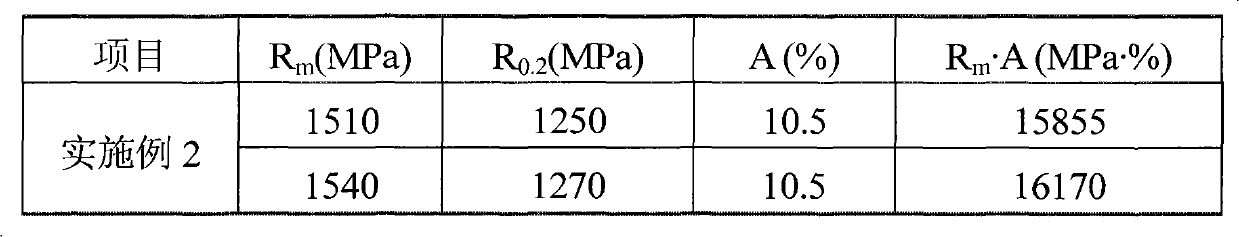

[0016] The thickness of the steel plate is 8mm, and the heat treatment process system is as follows: austenitization temperature 920°C, water quenching after holding time for 44 minutes, low temperature tempering at 200°C, holding time for 5 hours, and air cooling. Sampling and testing, the mechanical properties test values are shown in Table 2. Observed with a metallographic microscope, the metallographic structure is as follows figure 1 As shown, a large number of thin-scale martensitic strengthening phases can be observed. The solid solution rare earth La in steel can significantly reduce lath martensite bundles and improve the hardenability of steel.

[0017] Table 2 Mechanical property detection value

[0018]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com