Liquid whistle type ultrasonic emulsifier and method thereof for processing plant oil

A technology of ultrasonic emulsification and vegetable oil, applied in chemical instruments and methods, mixing methods, chemical/physical/physical-chemical processes of applying energy, etc., can solve the problems of insufficient power, high carbon residue, single restriction, etc. The effect of increasing, reducing raw material cost and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

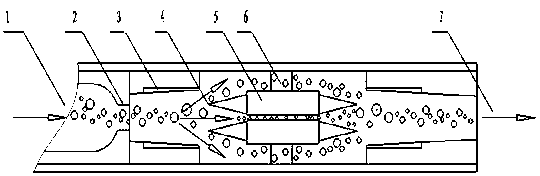

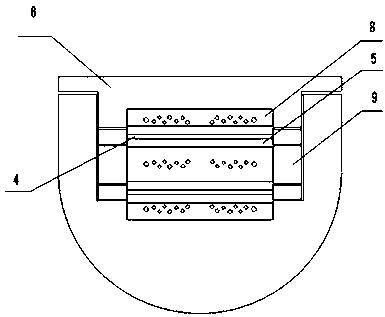

[0032] Embodiment 1, referring to the accompanying drawings, a liquid whistle type phacoemulsifier, including an inlet 1, a small opening 2, and an outlet 7 arranged on the housing, and the housing is provided with a core shooter 3, a resonance 5, and a phacoemulsifier arranged on the resonance 5 The reed 4, the inlet 1 and the outlet 7 are respectively arranged at both ends of the housing, the core shooter 3 is positioned by a key or a pin, the resonance 5 is arranged in the middle of the housing in two rows up and down, between the resonance 5 and the upper and lower housings Three fluid passages 8 are formed between the two resonators 5 , the resonator 5 and the reed 4 are an integrated structure and are fixedly installed in the groove on the housing through the gland 6 .

[0033] In this embodiment, the liquid whistle ultrasonic emulsifier is used in the method of vegetable oil treatment, and the process includes: coarse filtration, fine filtration, ratio control of vegetab...

Embodiment 2

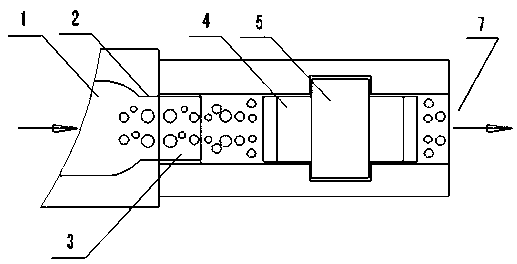

[0034] Embodiment 2, referring to the accompanying drawings, a liquid whistle type phacoemulsifier, including an inlet 1, a small opening 2, and an outlet 7 arranged on the housing, and the housing is provided with a core shooter 3, a resonance 5, and a phacoemulsifier arranged on the resonance 5 The reed 4, the inlet 1 and the outlet 7 are respectively arranged at both ends of the housing, the core shooter 3 is positioned by a key or a pin, the resonance 5 is arranged in the middle of the housing in two rows up and down, and a The pressure bar 9 forms a fluid channel 8 in the middle, and three fluid channels 8 are formed between the resonance 5 and the upper and lower shells and between the two resonances 5. The resonance 5 and the reed 4 are an integrated structure and are fixed and installed on the groove on the housing.

[0035] In this embodiment, the liquid whistle phacoemulsifier is used for the vegetable oil treatment method, see embodiment 1, wherein, the content of h...

Embodiment 3

[0036]Embodiment 3, referring to the accompanying drawings, a liquid whistle type phacoemulsifier, a liquid whistle type phacoemulsifier, comprising an inlet 1, a small port 2, and an outlet 7 arranged on the housing, and the housing is provided with a core shooter 3, The resonance 5 and the reed 4 arranged on the resonance 5, the inlet 1 and the outlet 7 are respectively arranged at both ends of the housing, the core shooter 3 is positioned by a key or a pin, and the resonance 5 is two rows up and down and is arranged in the middle of the housing , between the two rows of resonance 5 is provided with a bead 9, forming a fluid channel 8 in the middle, a total of three fluid channels 8 are formed between the resonance 5 and the upper and lower shells and between the two resonances 5, and the two ends of each resonance 5 are respectively set There is a composite reed including a cantilever reed and a fixed reed. The resonator 5 and the reed 4 are an integrated structure and are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com