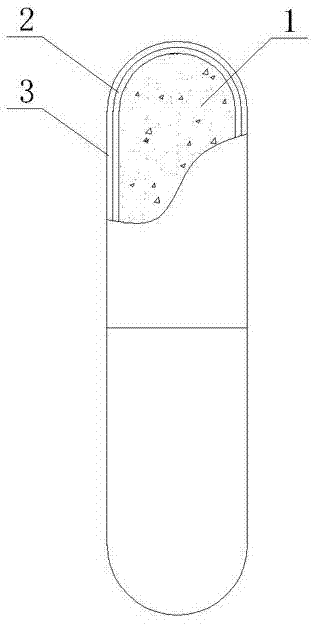

Photochromic double-shell microcapsule and preparation method and application thereof

A photochromic and photochromic material technology, applied in the field of functional polymer material preparation, can solve the problems of wide particle size distribution, easy adhesion, easy loss of photochromic organic solution, etc., to achieve wear resistance and durability Good, good processing resistance, the effect of maintaining photochromic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

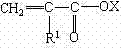

[0043] Mix and emulsify 10 parts of 6-nitro-1`,3`,3`-trimethylindoline spirochromene, 15 parts of polymer system regulator, and 200 parts of distilled water under high-speed shear at room temperature. Homogenize at medium and high speed for 30 minutes, and the homogenization rate is 10000rpm. Pour the homogenized emulsion into a three-necked flask, put it into a constant temperature water tank, add 0.5 parts of potassium persulfate under stirring conditions, raise the temperature to 80°C, and add 20 parts of formazan After cooling, adjust the pH value to 3-4 with acetic acid, add 1200 parts of etherified melamine resin dropwise at a stirring speed of 200 rpm, raise the temperature to 55°C, and keep it warm for 1.5 hours to complete the outer shell. One-layer wall building; then heated up to 65°C, kept warm for 1 hour, cooled, neutralized with ammonia water until the average H value was 7, obtained photochromic double-shell microcapsule solution, and dried to obtain powdery phot...

preparation Embodiment 2

[0049] At room temperature, mix and emulsify 10 parts of N-ethyl-3,3-dimethylspiroindoline naphthoxazine, 15 parts of polymer system regulator, and 200 parts of distilled water at high speed, that is, homogenize at medium and high speed for 30 minutes , the homogenization rate is 10000rpm, pour the homogenized emulsion into a three-necked flask, put it into a constant temperature water tank, add 0.5 parts of potassium persulfate under stirring conditions, raise the temperature to 80°C, and add 20 parts of ethyl methacrylate to carry out Build the inner wall, after cooling, adjust the pH value to 3-4 with acetic acid, add 80 parts of etherified melamine resin dropwise at a stirring speed of 200rpm, raise the temperature to 55°C, and keep it warm for 1.5h to complete the single wall building of the outer shell layer ; After cooling to room temperature, add 80 parts of etherified melamine resin dropwise again, heat up to 55°C, keep warm for 1.5h, carry out secondary wall building ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com