Modified asphalt and preparation method thereof

A technology for modifying asphalt and asphalt, applied in building components, building thermal insulation materials, buildings, etc., can solve problems such as poor stability of modified asphalt, and achieve improved temperature stability, thermal stability, good rheology, and good viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

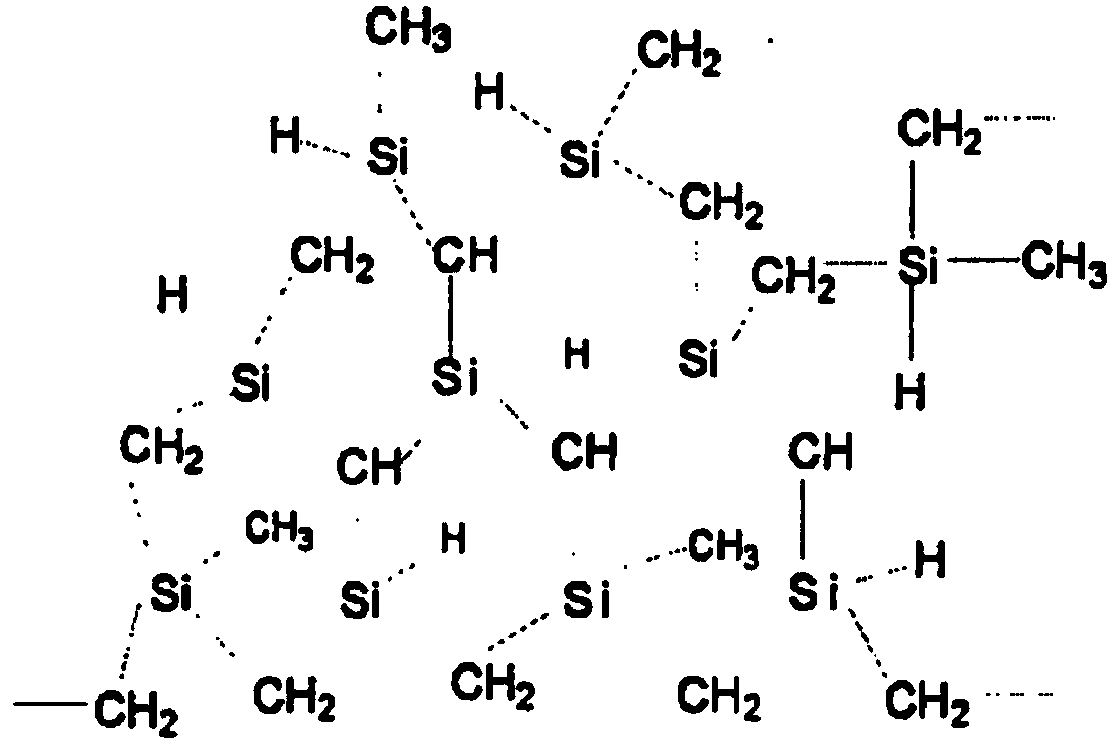

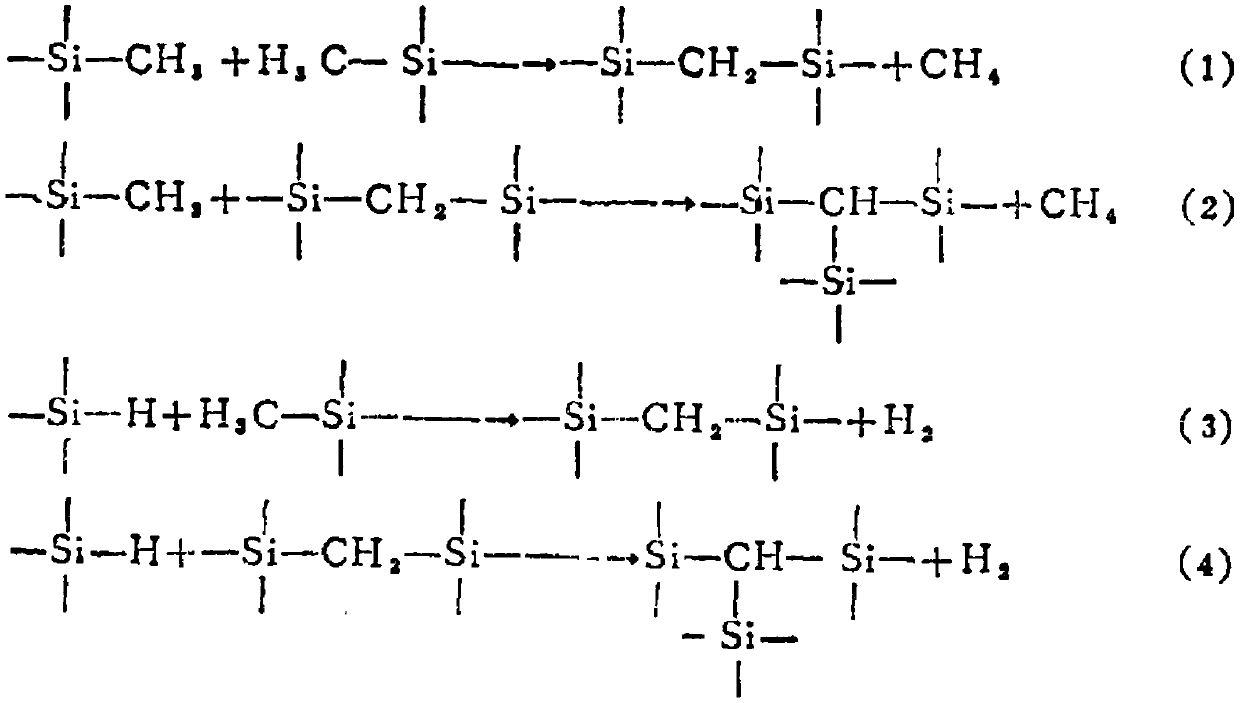

Method used

Image

Examples

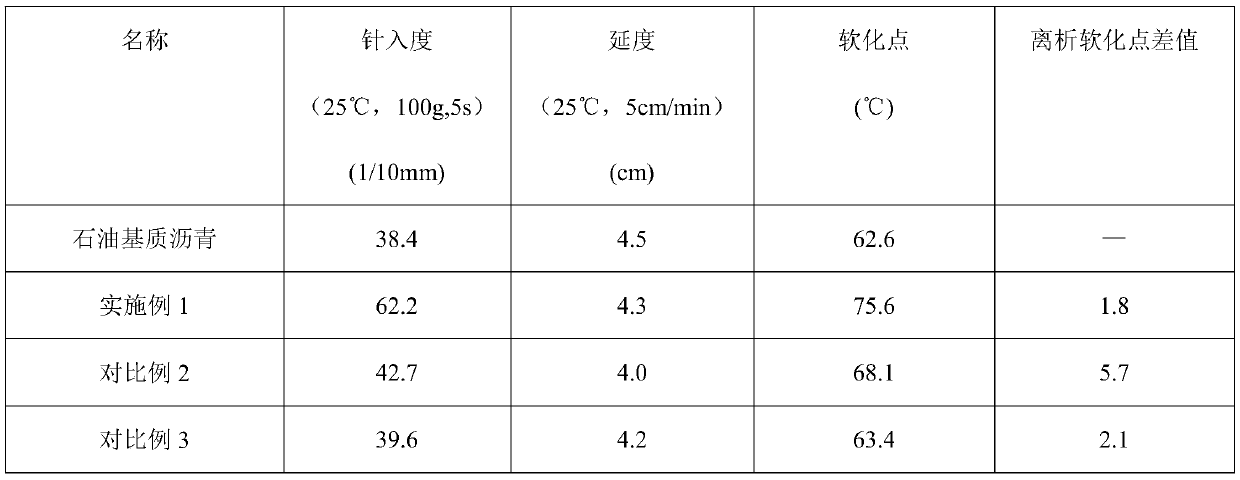

Embodiment 1

[0029] In the present embodiment, the preparation method of modified asphalt is as follows:

[0030] 1) In parts by weight, weigh 100 parts of petroleum-based asphalt, 15 parts of polycarbosilane powder (softening point 90°C, mesh number 4), and 8 parts of KH792 silane coupling agent, and set aside;

[0031] 2) Heat the petroleum base asphalt to 160°C, keep it warm under slow stirring (40r / min) and wait for the next process;

[0032] 3) Add the weighed polycarbosilane powder to the petroleum base asphalt, first stir at a slow speed (40r / min) for 7 minutes, then stir at a medium speed (80r / min) for about 6 minutes until the polycarbosilane powder is evenly dispersed, and obtain mixture A , and wait for the next process under slow stirring (40r / min) state;

[0033] 4) Add the weighed KH792 silane coupling agent into the mixture A, stir at a slow speed for 7 minutes, then stir at a medium speed (80r / min) for about 6 minutes until the silane coupling agent is uniformly dispersed;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com