Low humidity steam flash double effect heat exchange system

A technology of heat exchange system and low humidity, which is applied in the field of low humidity steam flash two-effect heat exchange system, which can solve the problems of decreased drainage capacity, affecting normal production, low heat exchange efficiency and energy efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

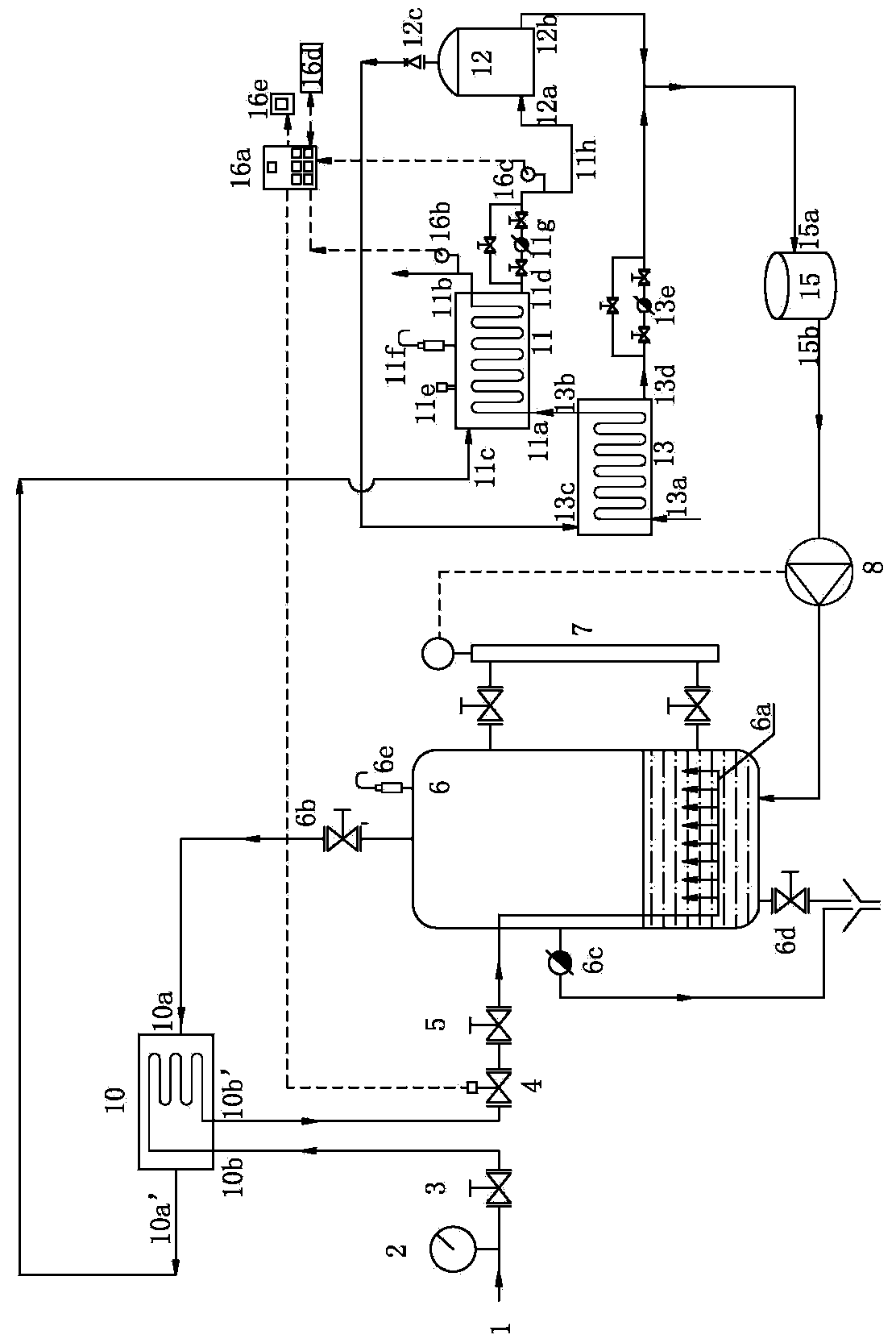

[0016] Such as figure 1 As shown, the low-humidity steam flash two-effect heat exchange system of the present invention includes a superheated steam pipe, a water bath type saturated steam generator 6, a make-up water pump 8, a steam drying heat exchanger 10, a main steam heat exchanger 11, a flash evaporation tank 12, flash steam heat exchanger 13, water collection tank 15 and PLC controller 16a.

[0017]The lower part of the cylinder of the water-bath saturated steam generator 6 is a liquid phase space, and the upper part of the cylinder is a vapor phase space. The top wall of the vapor phase space is provided with a water-bath saturated steam generator exhaust valve 6b, and the water-bath saturated steam generator A flow divider 6a is provided in the liquid phase space of 6 . A water level gauge 7 and an overflow valve 6c are installed on the side wall of the water bath type saturated steam generator 6, and the overflow valve 6c can be a ball float type steam trap. The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com