Light-emitting diode (LED) light-distributing lens

A light distribution lens and lens technology, applied in the direction of light source, fixed light source, point light source, etc., can solve the problems of inability to meet the requirements of high-end lighting occasions, limited ability to homogenize and modulate the light field, uneven color of the lighting area, etc. Flexible control of angle and area distribution, overcoming the phenomenon of uneven color distribution, overcoming the effect of uneven color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

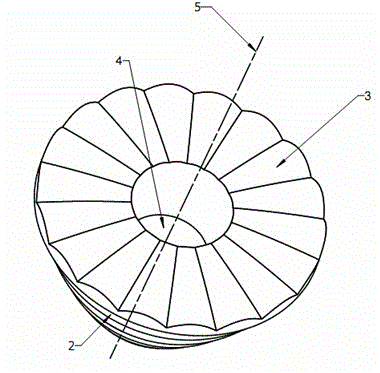

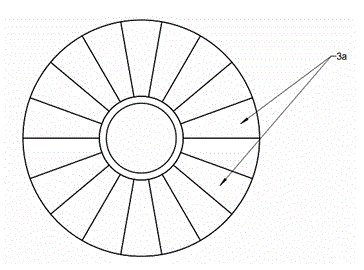

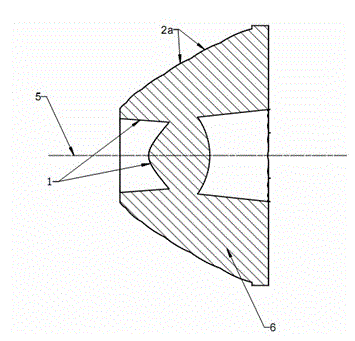

[0045] Such as Figure 1 to Figure 3 As shown, the LED light distribution lens of the present invention includes a lens body 6. The shape of the lens body 6 is approximately conical. The bottom is concave, and the LED light source can be installed in the concave space area. The incident surface 1 is used to receive the light of the LED light source close to this side, and the light of the LED light source is refracted by the incident surface 1 to form incident light inside the lens body 6; The reflection surface 2 is arranged on the side of the lens body 6, and is used for redirecting and reflecting the light inside the lens body 6 to the exit surface. After the light is refracted, it is emitted and projected to the illuminated area. The reflective surface 2 is sequentially spliced by several annular surfaces 2a arranged along the axial direction of the lens body 6. The diameters of the several annular surfaces 2a are gradually increased from the incident surface 1 to the ex...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that the generatrix of the annular surface 2a is a curve. By changing the curvature of the generatrix on the annular surface 2a, the reflected light can be accurately irradiated in the illumination area as required, which is more conducive to the light in the illumination area. Flexible adjustment within.

[0051] Please refer to Embodiment 1 for other structures.

Embodiment 3

[0053] The difference between this embodiment and Embodiment 1 lies in that the generatrix of the annular surface 2a is a straight line, and in this way, the light extraction efficiency is high, and the processing and manufacturing are convenient.

[0054] Please refer to Embodiment 1 for other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com