Combined heating and power system of heat source complementary Stirling engine and method of system

A Stirling engine and combined heat and power technology, which is applied in hot gas variable capacity engine devices, solar thermal power generation, machines/engines, etc. Improve overall energy efficiency, facilitate grid connection, improve stability and sustainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described with reference to the accompanying drawings.

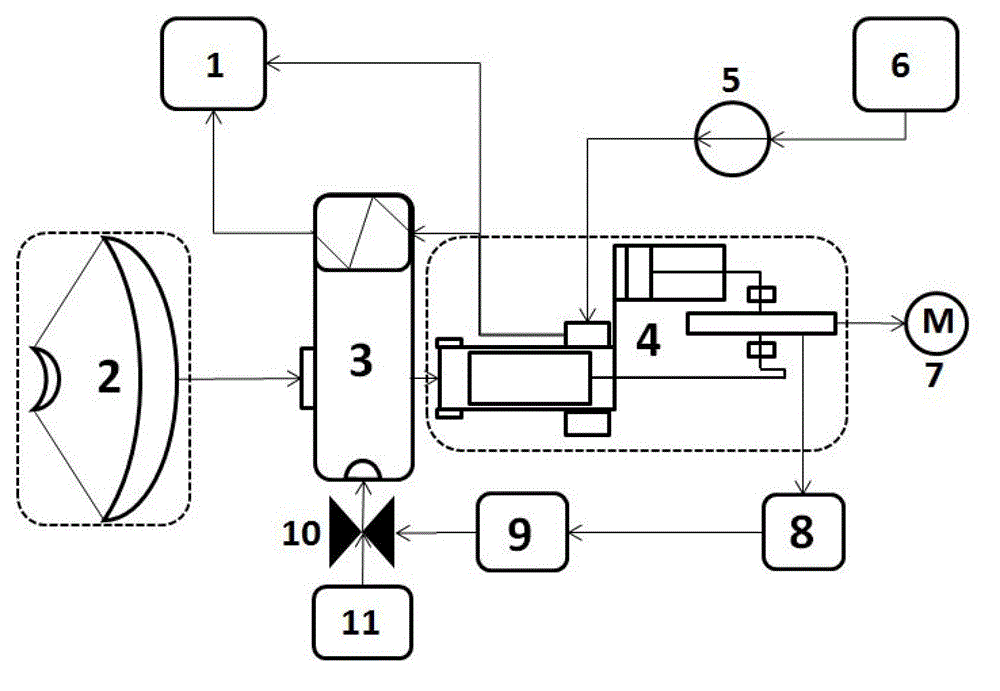

[0027] like figure 1 As shown, the heat source complementary Stirling engine combined heat and power system includes a hot water tank 1, a dish-type secondary reflector 2, a mixed heat source heater 3, a Stirling engine 4, a water pump 5, a cold water tank 6, and a generator 7 , data acquisition and detector 8, auxiliary heat source controller 9, electric control valve 10 and fuel replenishment device 11; dish-type secondary reflector 2 focuses the sunlight to the hybrid heat source heater 3, and the hybrid heat source heater 3 and Ster The hot end of the forest engine 4 is connected, the output terminal of the Stirling engine 4 is connected with the generator 7, the cold water tank 6, the water pump 5, the cooler circuit of the Stirling engine 4, and the flue gas side exchange in the mixed heat source heater 3 The heater is connected to the hot water tank 1 in sequence, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com