Double-power-driven system for concrete wet-spray platform vehicle and concrete wet-spray platform vehicle

A dual power drive, concrete technology, applied in earthwork drilling, machine/engine, wellbore lining, etc., can solve the problems of large hydraulic system, high failure rate, and high cost, and achieve simple hydraulic system, good economy, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make those skilled in the art better understand the technical solution of the present invention, the content of the present invention is described below in conjunction with accompanying drawing:

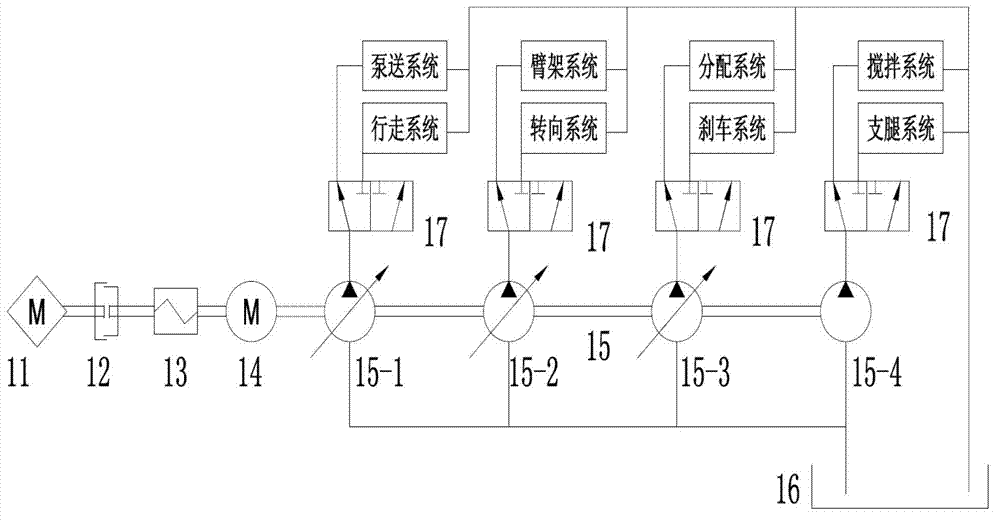

[0024] figure 1 It is a structural schematic diagram of a dual-power drive system for a concrete wet spraying trolley provided in the first embodiment of the present invention, figure 1 Among them, the dual power drive system for the concrete wet spraying trolley is used to drive the pumping system, walking system, boom system, steering system, distribution system, brake system, mixing system, outrigger system, including: 11 diesel engines, 12 Clutch, 13 gearbox, 14 double shaft extension motor, 15 quadruple pump set, 16 oil tank, 17 switching valve; 15 quadruple pump set includes 15-1 first plunger pump, 15-2 second plunger pump, 15-3 third plunger pump, 15-4 gear pump.

[0025] 11 The power output end of the diesel engine is connected to the input end of the 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com