Twisting and spooling combine

An all-in-one machine and tube-forming technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of insufficient support, easy deformation, and low strength of paper tubes, so as to prevent falling off or Radial rotation, prevent loosening up and down, good locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

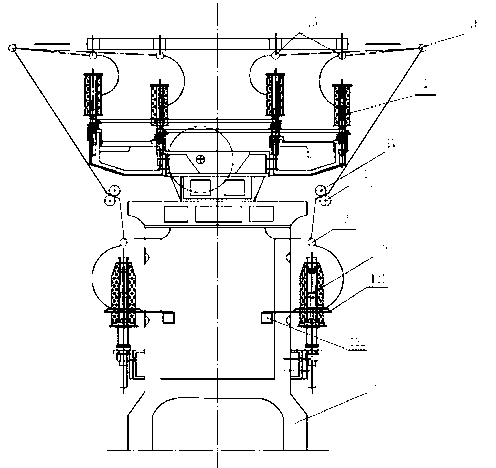

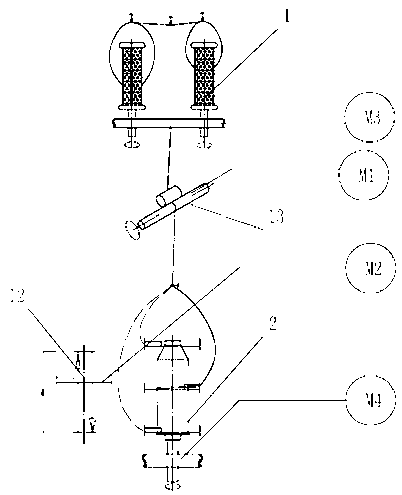

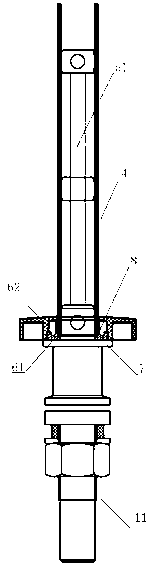

[0076] An integrated twisting machine, comprising an upper spindle assembly 1, a lower spindle assembly 2, and an introduction guide 3 for feeding the thread to the lower spindle assembly 2, the upper spindle assembly 1 guides the thread through the The silk device 3 is delivered to the lower spindle assembly 2, the lower spindle assembly 2 includes a bobbin 4, a rotating shaft 5 and a base 6, the rotating shaft 5 is provided with a base support member 7, and the base 6 is provided with There is a locking member 8, the base 6 is fixed on the rotating shaft 5 through the base support member 7, the bobbin 4 is sleeved on the rotating shaft 5, and the bobbin 4 is fixed on the base 6 through the locking member 8 superior.

[0077]In the present invention, the base 6 is provided with an inlaid cavity, and an inlaid core 61 is provided in the inlaid cavity, the locking member 8 is arranged on the inlay core 61, and the bobbin 4 is fixed on the inlay core 61 through the locking membe...

Embodiment 2

[0110] The difference from Implementation 1 is that: the length of the supporting ball protruding from the outer surface of the annular flange is 3 mm; there are three supporting balls on the upper annular flange and the lower annular flange, forming three points respectively. The positioning support structure; the outer diameter of the annular flange is 30mm, the width is 25mm, the distance between the two adjacent annular flanges is 85mm; the diameter of the supporting ball is 9mm. The locking member 8 is at least equally divided into five arc-shaped locking blocks 10 , and each locking block 10 is provided with an anti-slip protrusion 9 .

Embodiment 3

[0112] The difference from Implementation 1 and 2 is that: the length of the supporting ball protruding from the outer surface of the annular flange is mm; the supporting balls on the upper annular flange and the lower annular flange are three, respectively forming Three-point positioning support structure; the outer diameter of the annular flange is 30 mm, the width is 26 mm, and the distance between two adjacent annular flanges is 90 mm; the diameter of the supporting ball is 10 mm.

[0113] The locking member 8 is at least equally divided into eight arc-shaped locking blocks 10 , and each locking block 10 is provided with an anti-slip protrusion 9 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com