Method for preparing cadmium telluride/ferroferric oxide magnetic fluorescent fiber through in-situ method

A technology of ferroferric oxide and fluorescent fibers, applied in chemical instruments and methods, chemical characteristics of fibers, luminescent materials, etc., can solve the problems of poor dispersion of quantum dots, and achieve the effect of simple method and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

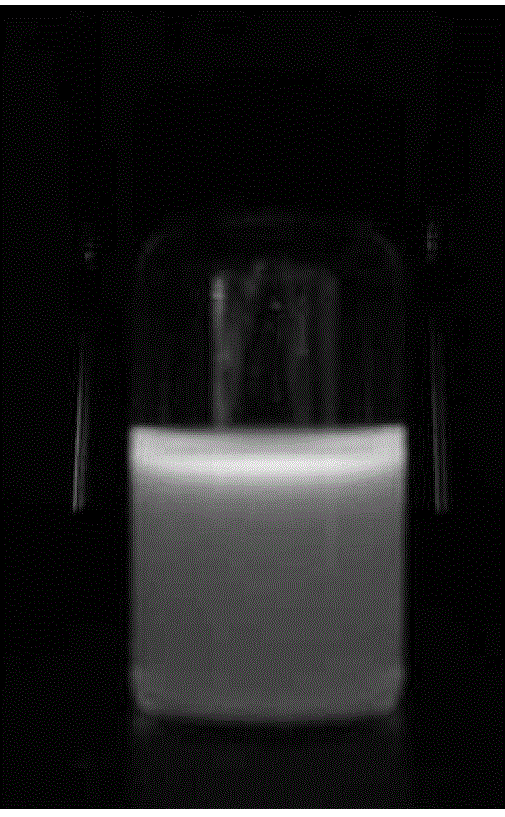

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment 1: The method for preparing cadmium telluride ferromagnetic fluorescent fiber by in-situ method in this embodiment is as follows:

[0021] 1. Add 0.36g~0.3612g sodium borohydride, 6mL deionized water and 0.51g~0.5146g tellurium powder into a 25mL round bottom flask, and put the round bottom flask under the condition of 0℃~4℃ ice water bath Stir on the stirrer at a stirring speed of 200rpm to 300rpm, react for 10h, and obtain a sodium telluride hydride solution;

[0022] 2. Add 0.02g of sodium hydroxide to 40mL of deionized water, and stir until the sodium hydroxide is completely dissolved to obtain a sodium hydroxide solution;

[0023] 3. Add 24g polyvinyl alcohol to 376g deionized water, then raise the temperature to 60°C and keep the temperature constant for 2-3 hours, then raise the temperature to 90°C and keep the temperature constant for 4-5 hours to obtain a polyvinyl alcohol solution;

[0024] 4. Take 250 mL of the polyvinyl alcohol solution ...

specific Embodiment approach 2

[0026] Specific embodiment 2: the difference between this embodiment and specific embodiment 1 is that in step 1, stir at a stirring speed of 250 rpm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment is different from Embodiment 1 in that in step 3, the temperature is raised to 60° C. and kept at a constant temperature for 2.5 hours. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com