Preparation method of dissolved oxygen sensing membrane head and dissolved oxygen sensing membrane head

A technology for sensing film and dissolved oxygen, which is applied in the manufacture of microstructure devices, processes for producing decorative surface effects, fluorescence/phosphorescence, etc., which can solve the problems of easy fall off of the fluorescent layer and long response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

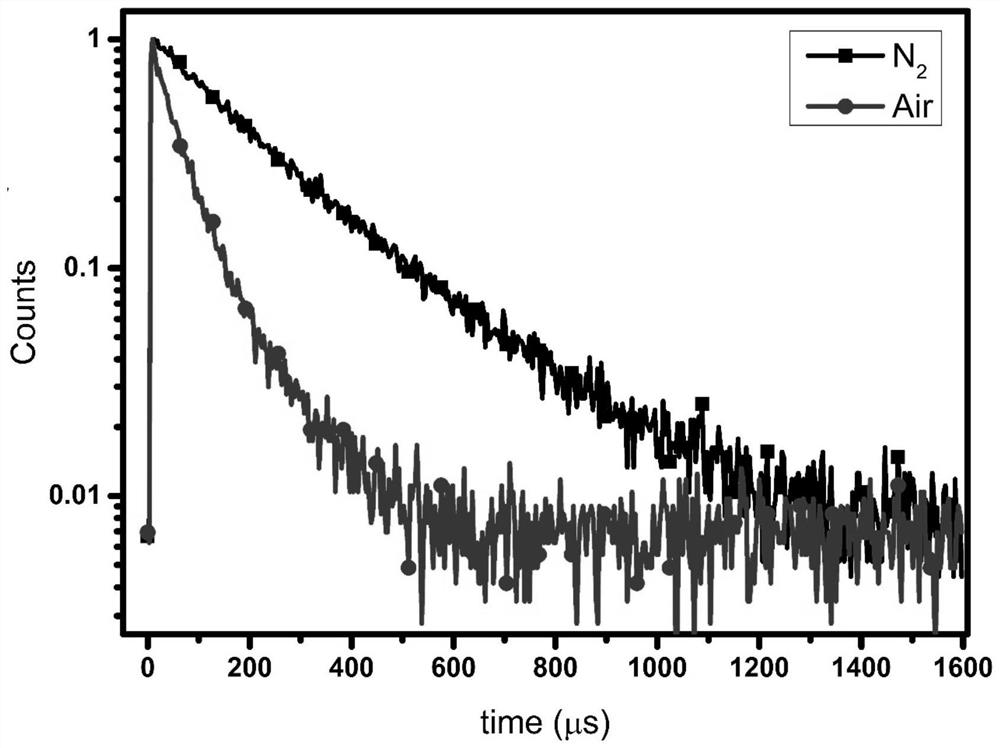

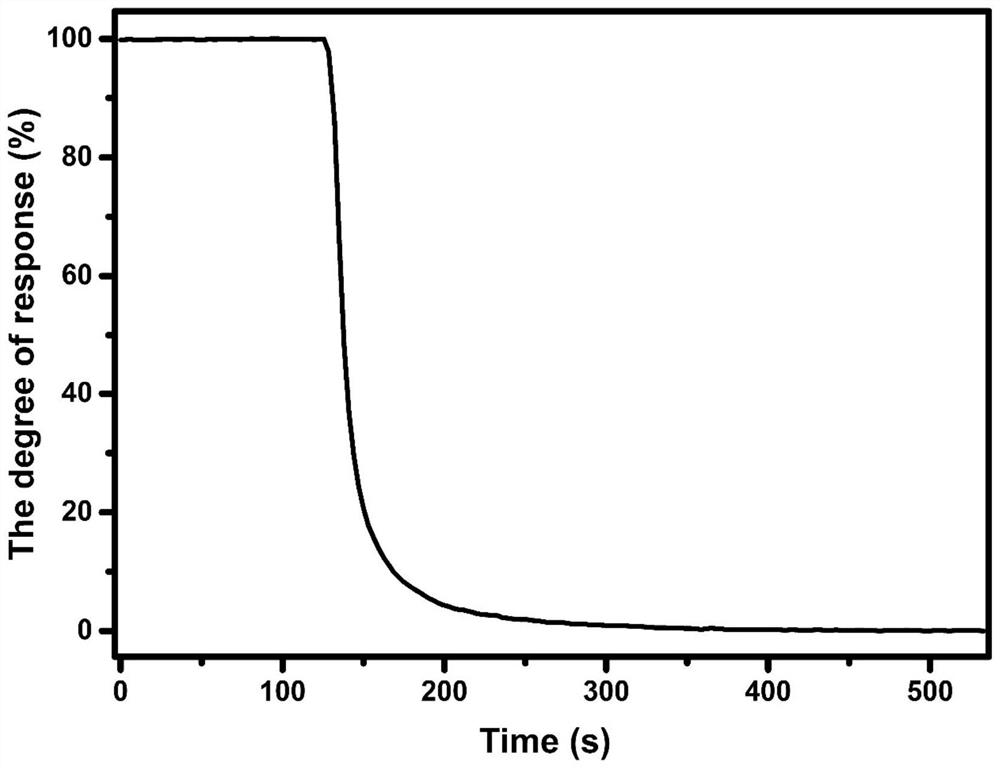

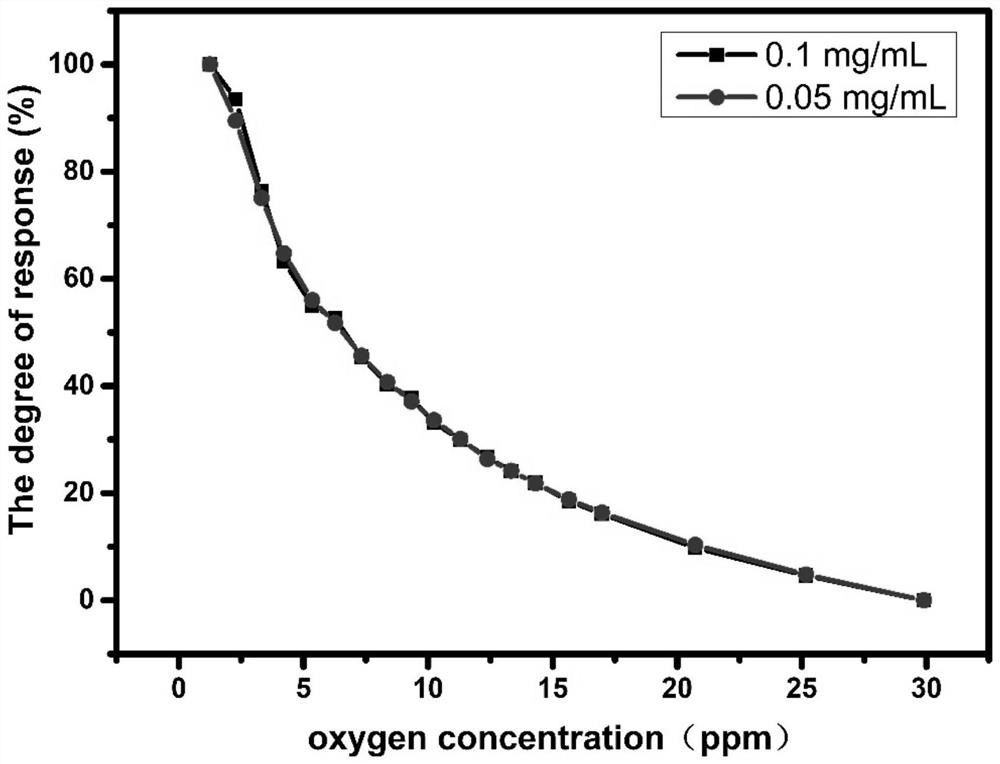

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of a dissolved oxygen sensing membrane head, comprising the following steps:

[0032] Preparation of fluorescent layer: Dissolve 18-22 parts by mass of the indicator in 0.8-1.2 parts by volume of tetrahydrofuran solution to obtain an indicator solution, and add the indicator solution to 18-22 parts by volume of 2wt% polyphenylene-containing solution under stirring In the emulsion of ethylene microspheres, stir for 50-70min to obtain the first mixed solution; then add 0.08-0.12 parts by volume of 0.1M calcium chloride aqueous solution to the first mixed solution, stir for 28-32min, and then ultrasonicate for 4-6min to obtain the second Mixed solution; pour the second mixed solution onto the quartz plate, volatilize at room temperature for 7.5-8.5 hours, and dry at 95-105° C. for 28-32 minutes to solidify to obtain a fluorescent layer; the 1 part by mass: 1 part by volume=1 mg: 1ml; wherein, the indicator is octaethylporphyrin platinum.

[0033] Prep...

Embodiment 2

[0052] This embodiment provides a dissolved oxygen sensing membrane head, which is prepared by the preparation method of a dissolved oxygen sensing membrane head described in any one of the embodiments of the first embodiment; including a quartz plate, a fluorescent layer, a light-reflecting layer and a light-shielding layer .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com