Device for rapid annealing of semiconductor silicone chip

A rapid annealing, semiconductor technology, applied in crystal growth, post-processing details, post-processing and other directions, can solve problems such as affecting the recovery of silicon single crystals to the true resistivity, and achieve strong industrial operability, high efficiency, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

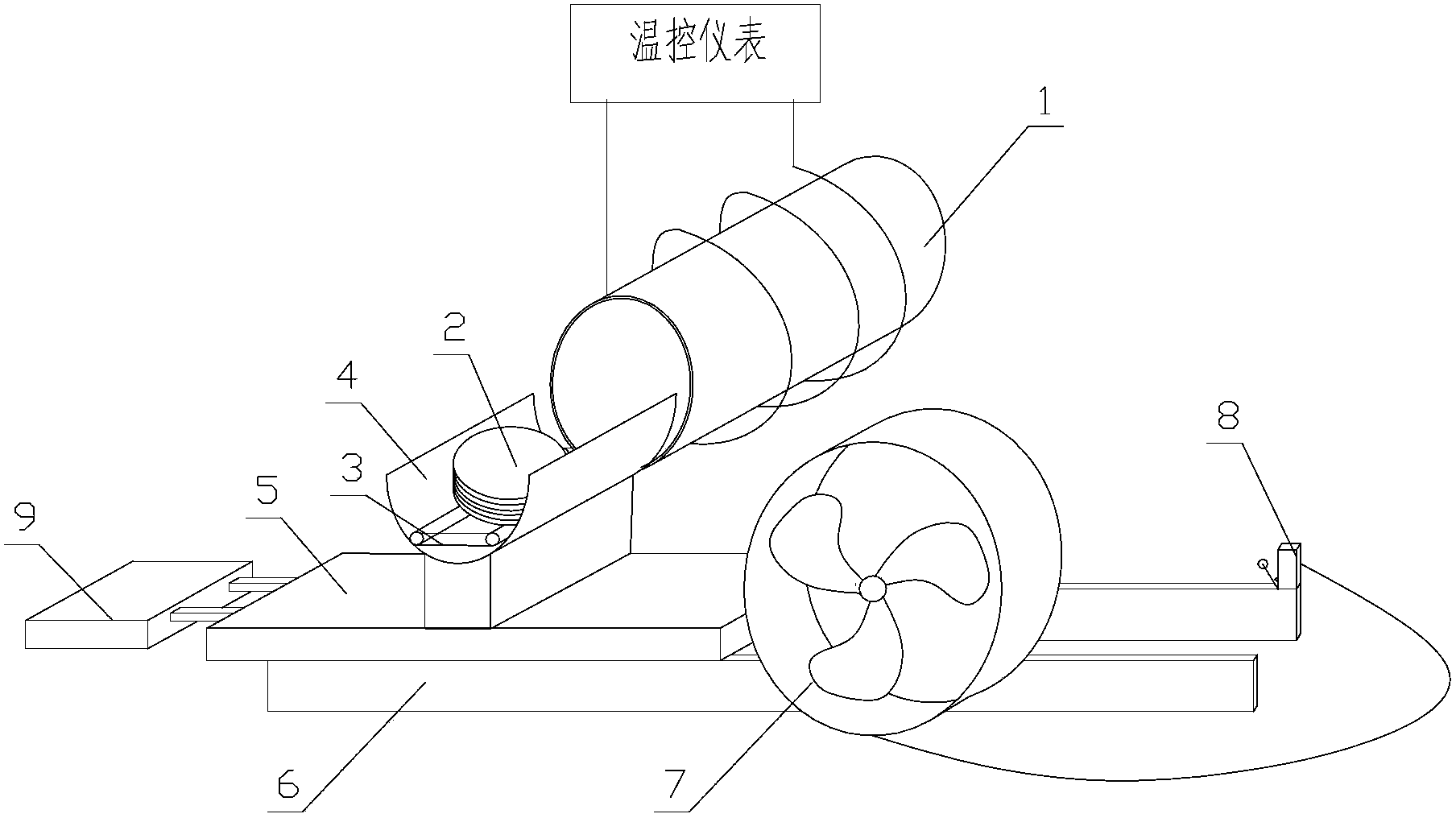

[0023] Combine below figure 1 Specifically illustrate an embodiment of a device for rapid annealing of semiconductor silicon wafers of the present invention, comprising a support bracket 4 that receives the semiconductor silicon wafer 2 from the heat treatment furnace 1, a mobile slide 5 fixedly connected to the support bracket 4, and cooperating with the mobile slide 5 The sliding guide rail 6, the device also includes a contact switch 8 located on the sliding guide rail and the cooling fan 7 controlled by the contact switch. The contact switch controls the cooling fan to be turned on, and the mobile slide plate 5 is driven by the drive mechanism to slide on the sliding guide rail. Described driving mechanism is an air cylinder 9, and this air cylinder is closed by the control of contact switch 8.

[0024] The support bracket is a plate with an arc-shaped cross section, and the support bracket has the same radian as the lower half of the furnace mouth of the heat treatment f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com