Preparation method of polysilicon thin film and optoelectronic device

A technology of polysilicon thin film and amorphous silicon thin film, applied in the direction of electrical components, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of restricting wide application, expensive equipment, MIC metal pollution, etc., achieve large-area preparation process, reduce The effect of preparation cost and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

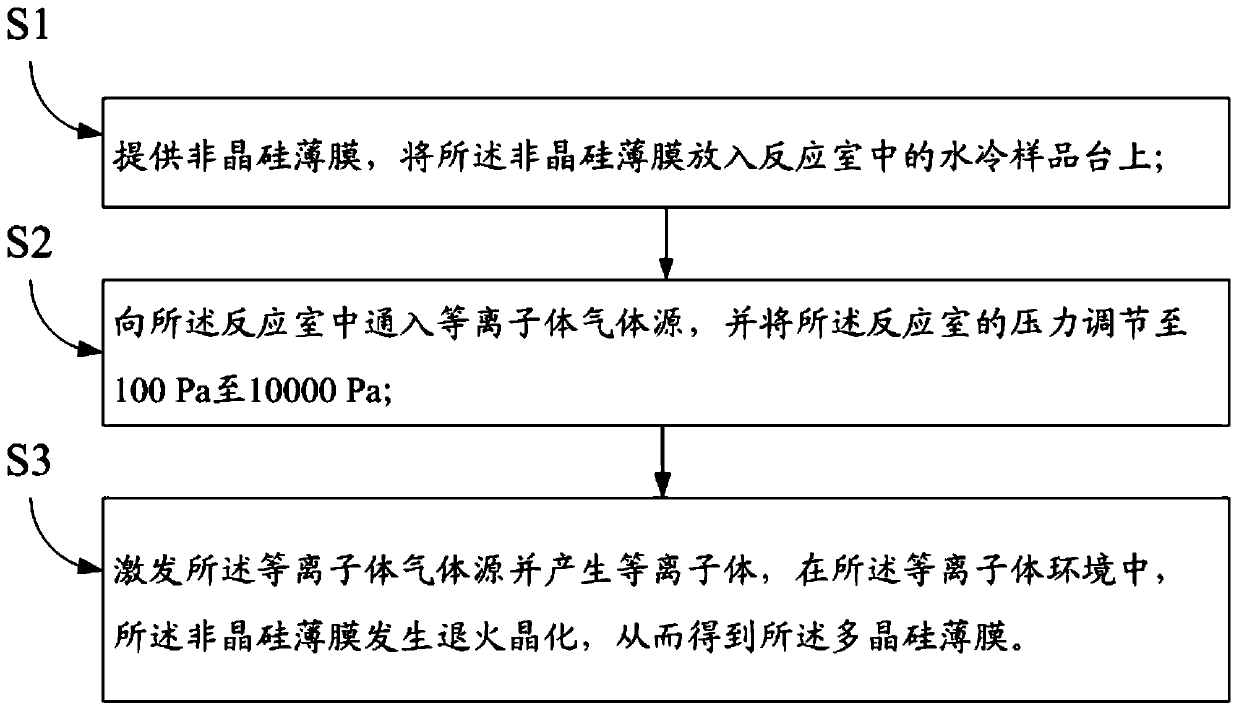

[0027] See figure 1 , The present invention provides a method for preparing a polysilicon film, which includes the following steps:

[0028] S1, providing an amorphous silicon film, and placing the amorphous silicon film on a water-cooled sample stage in the reaction chamber;

[0029] S2: Pass a plasma gas source into the reaction chamber, and control the pressure of the reaction chamber to 100 Pa to 10000 Pa;

[0030] S3. Excite the plasma gas source and generate plasma. In the plasma environment, the amorphous silicon film is annealed and crystallized, thereby obtaining the polysilicon film.

[0031] In step S1, a substrate may be further provided for supporting the amorphous silicon film. The substrate may be a silicon wafer with higher purity, or ordinary quartz glass. The amorphous silicon film may be deposited on the substrate first, and then the substrate deposited with the amorphous silicon film may be placed in the reaction chamber.

[0032] The thickness of the amorphous sil...

Embodiment 1

[0046] Deposit a 1μm thick amorphous silicon film on the cleaned 3cm×3cm silicon wafer substrate, take out the sample and install it on the water-cooled sample stage of the medium pressure plasma CVD equipment, adjust the height of the sample stage to make the surface of the substrate The distance from the plasma spray gun outlet is 30mm, close the vacuum chamber and pump the vacuum chamber to 10 -5 Pa background vacuum degree, close the gate valve connecting the molecular pump set and the cavity, open the process pump set and pressure control valve, pass in high purity Ar with a flow rate of 20slm, and adjust the pressure control valve to make the vacuum chamber The pressure reaches 800Pa, and the high purity H with a flow rate of 0.5slm 2 And turn on the radio frequency power supply to generate plasma, adjust the power of the radio frequency power supply to 14kW, the annealing temperature is 552℃, and the annealing time is 7s. Close H after annealing 2 , Turn off the plasma po...

Embodiment 2

[0048] This embodiment is basically the same as embodiment 1, except that the substrate is a quartz glass substrate, and the plasma gas sources are Ar and H 2 The flow rate of the plasma gas source is 10slm, the cavity pressure of the reaction chamber is 200Pa, the annealing power is 16kW, the annealing time is 5s, and the annealing temperature is 600°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com