Demulsifying dehydration method of oilfield produced liquid

A production fluid and oilfield technology, applied in the direction of chemical dehydration/emulsification, etc., to achieve the effect of wide application range, convenient industrial application, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

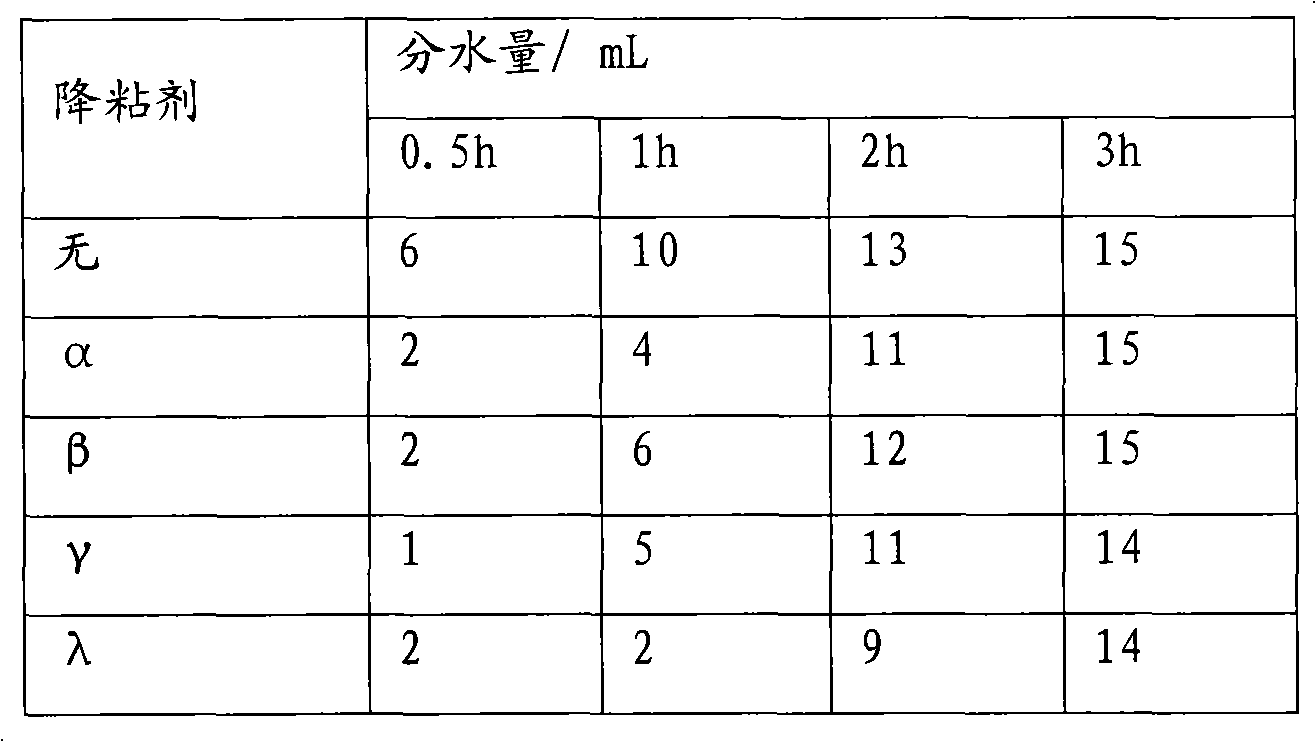

[0028] The water content of the production fluid is 20%, the addition of emulsifying viscosity reducer is 200ppm, and the demulsification aid is liquid polyaluminum chloride (product index: alumina content ≥ 10.0%, basicity 40.0%-85.0%, water insoluble content ≤0.5), the addition amount is 150ppm, the results are shown in Table 1.

[0029] Table 1

[0030]

Embodiment 2

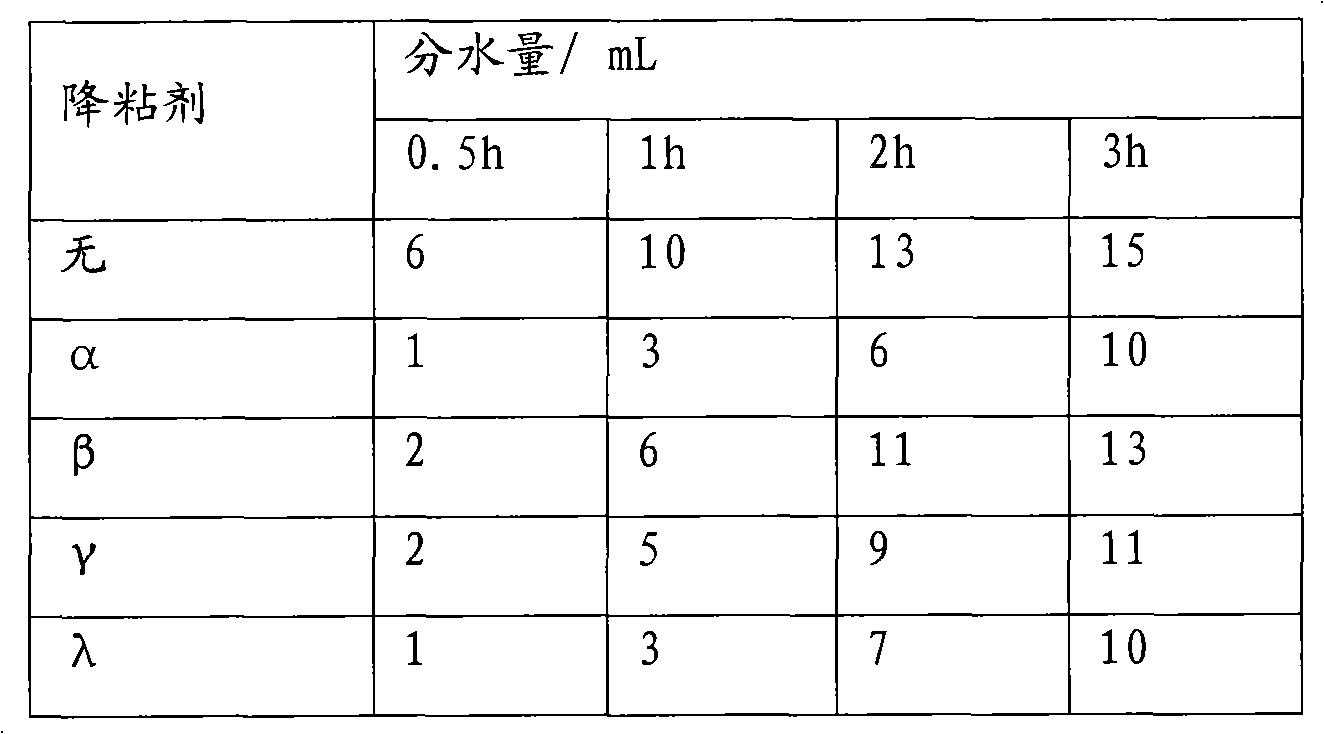

[0036] The water content of the production fluid is 20%, the addition of emulsifying viscosity reducer is 300ppm, and the demulsification aid is liquid polyferric sulfate (product index: total iron content ≥ 11.0%, basicity 9.0%-14.0%, water insoluble content ≤ 0.3), addition 200ppm, the results are shown in Table 3.

[0037] table 3

[0038]

Embodiment 3

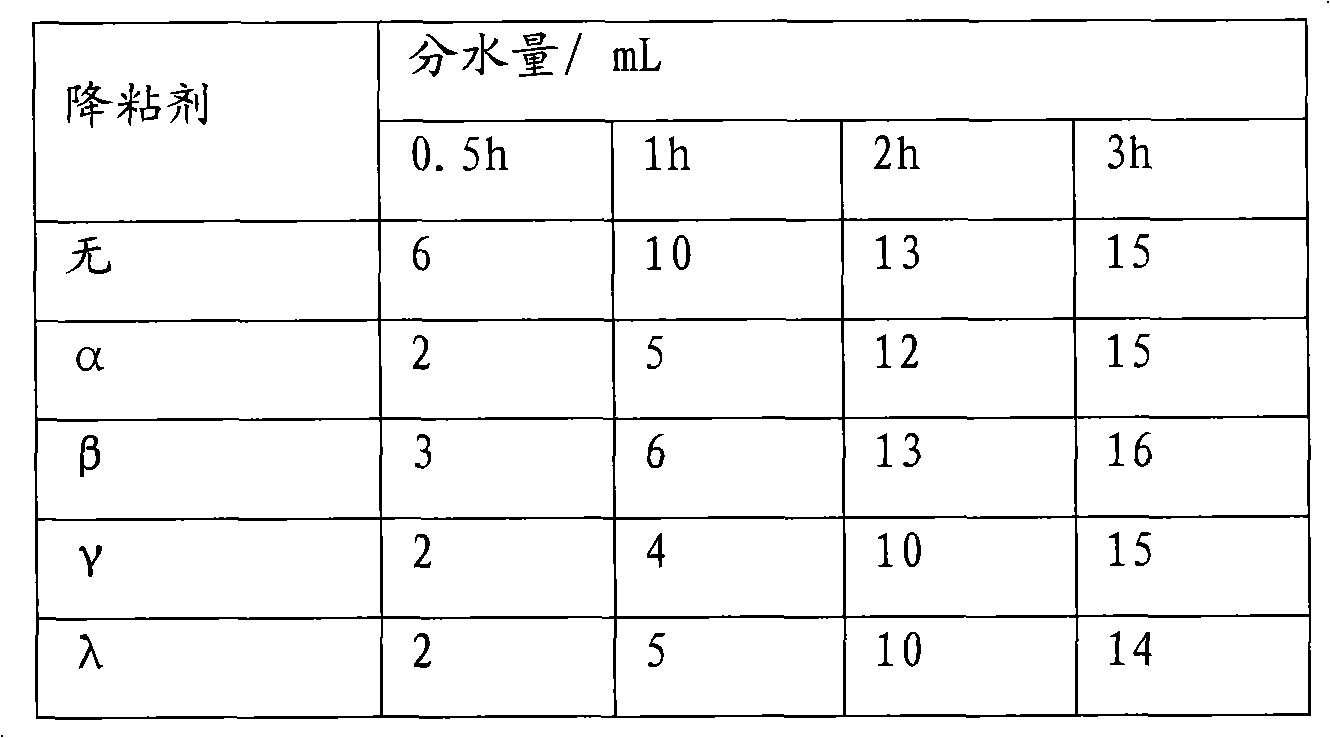

[0044] The water content of the production fluid is 30%, the addition of emulsifying viscosity reducer is 500ppm, and the demulsification aid is polyaluminum ferric chloride (product index: alumina content ≥ 27.0%, iron oxide content 3.0%-6.0%, basicity ≥ 70.0%, water-insoluble content≤0.75%), the addition amount is 500ppm, and the results are shown in Table 5.

[0045] table 5

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com