Preparation method of phthaloyl azo dye

A technology of phthalimide-based azo and dyes, which is applied in the preparation of phthalimide-based azo dyes, two asymmetric structure nitro compounds in the field of preparing azo dyes, can solve a large number of problems Inorganic salts, waste water, environmental impact and other issues, to achieve the effect of high safety, low energy consumption, and short synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

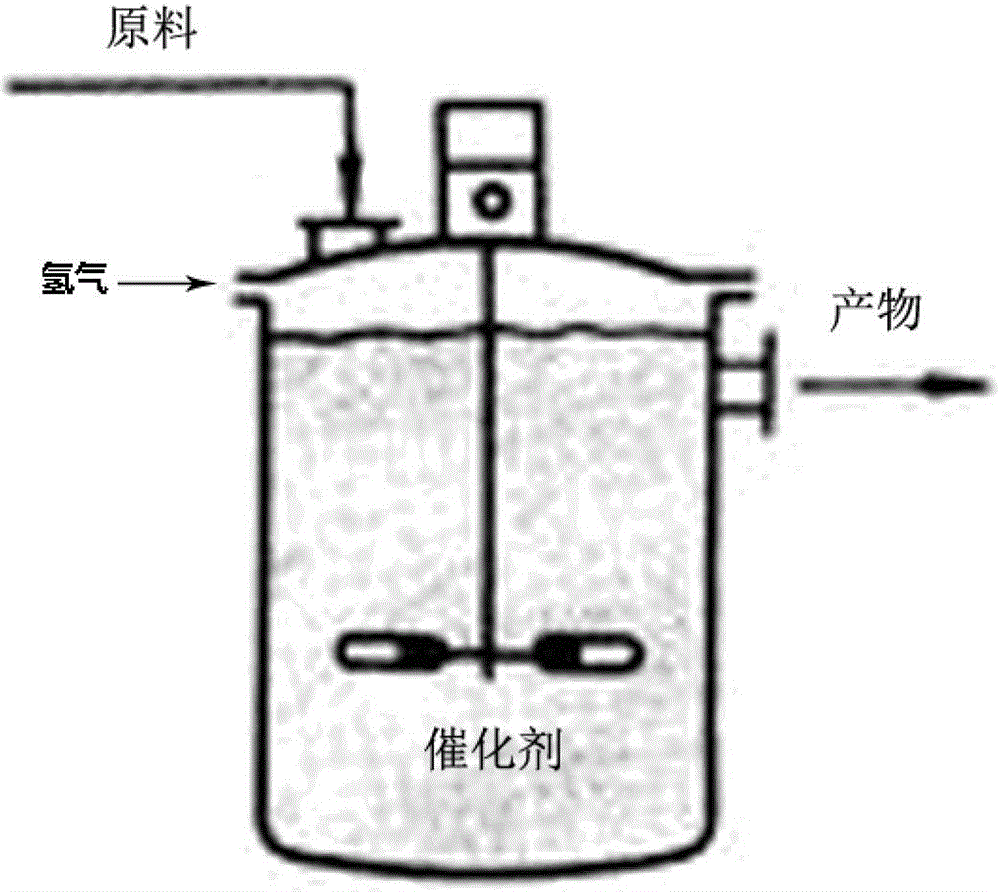

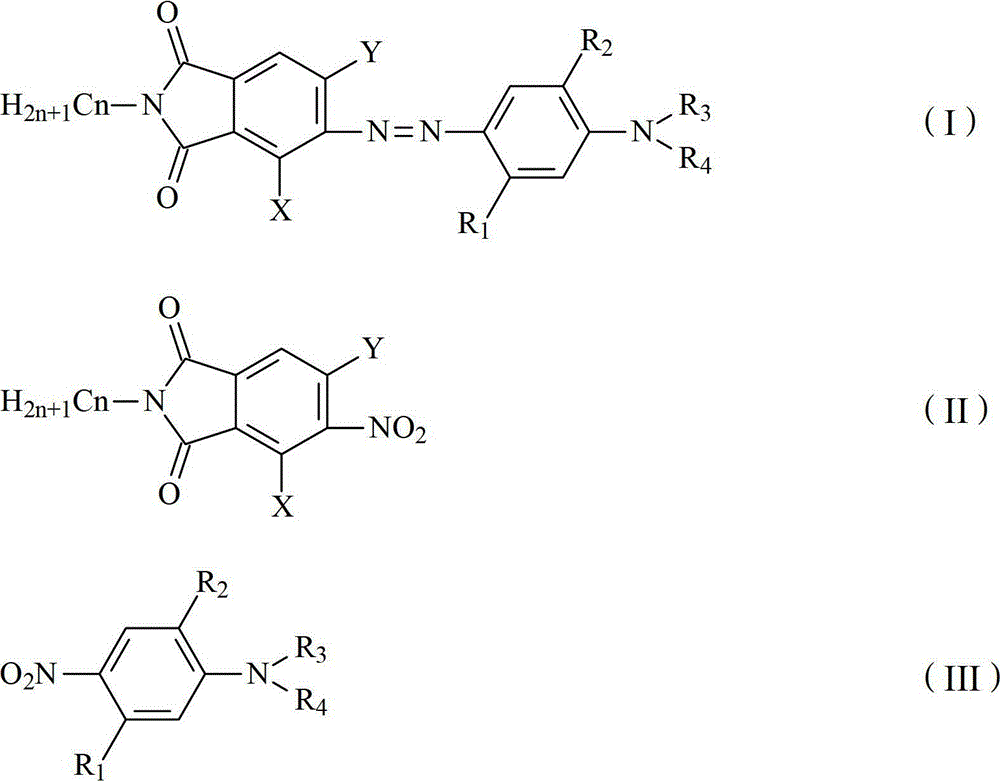

[0018] A method for preparing a phthalimide-based azo dye, comprising mixing a compound of formula (II) and a compound of formula (III) in equimolar proportions, adding them to a solvent containing alkali, and passing hydrogen gas in the presence of a catalyst , react at room temperature to 98°C for 4 to 24 hours under low pressure (0.1 to 0.2 MPa) or normal pressure to directly prepare the compound of formula (I) with azo structure.

[0019]

[0020] Among them, in formula (I), formula (II) and formula (III), n=1, 2 or 3; X is -H, -CH 3 、-C 2 h 5 , -Cl, -Br; Y is -H, -Cl, -Br; R 1 -H, -CH 3 , -NHCOCH 3 , -NHCOC 2 h 5 ; 2 -H, -CH 3 ; 3 with R 4 Same as -C 2 h 4 OCH 3 、-C 2 h 4 OC 2 h 5 、-C 2 h 4 OCOCH 3 、-C 2 h 4 OCOC 2 h 5 ;

[0021] The catalyst is one of Pt nanomaterials, Pd nanomaterials or a mixture of both.

[0022] The diameter of the catalyst is 2nm-3nm.

[0023] Preferably, the amount of the catalyst accounts for 0.01wt%-1wt% of the compo...

Embodiment 1

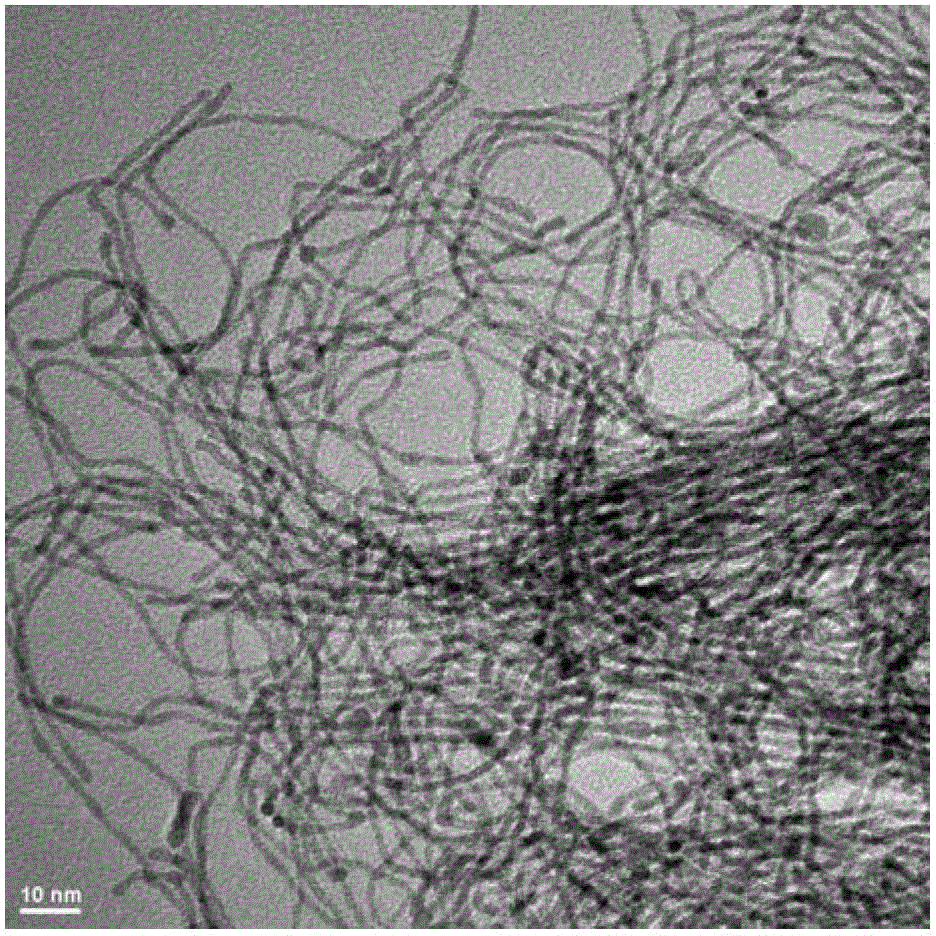

[0029] Synthesis of platinum nanowires: Platinum acetylacetonate was reduced in oleylamine at 160°C while iron pentacarbonyl was thermally decomposed to obtain Fe / Pt nanowires with a diameter of 2nm to 3nm (see Angew.Chem.Int.Ed.46(2007), 6333 -6335), and then heated and stirred under acidic conditions to corrode the Fe wrapped on the outside of the Pt nanowires to obtain platinum nanowires. Scanning the obtained nanowires with an electron microscope, the results are shown in the attached figure 2 , from attached figure 2 It can be seen that the diameter of the platinum nanowires is 2 nm to 3 nm.

Embodiment 2

[0031] In a reaction flask of 20g m-xylene, 2.85g compound (IIA) and 3.09g compound (IIIA) were firstly added, and then 0.4g sodium hydroxide and 1.4mg platinum nano-compound were added respectively. Put the system into an autoclave, cool, vacuumize, release hydrogen, cycle 3 to 4 times, put in hydrogen, and return to room temperature. The system was kept in an oil bath at 80°C with a hydrogen pressure of 0.2Mpa, and the product (IA) was obtained after heating for 15h with a yield of 78%.

[0032]

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com