Flame-retardation enhanced epoxy plastic sheet material and its preparation method

A technology of epoxy plastics and plates, applied in the field of polymer material modification and processing, can solve the problems of high cost, high price, unfavorable development of the automobile industry, etc., and achieve the effect of low cost, long life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

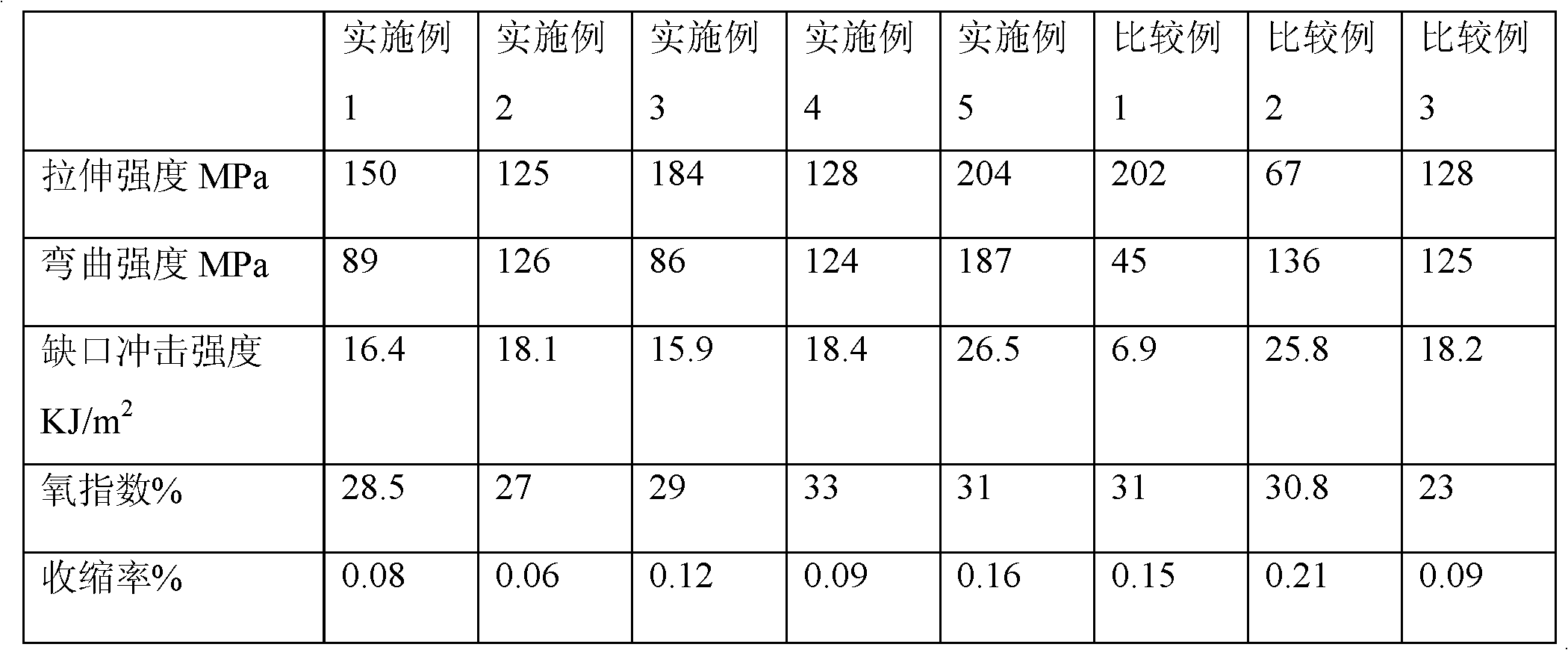

Examples

Embodiment 1

[0039] Add 100 parts of epoxy resin, 8 parts of dioctyl phthalate, 5 parts of EPDM rubber, 100 parts of glass fiber, 30 parts of quartz powder, and 10 parts of allyl glycidyl ether into the reaction kettle according to the formula ratio , stirring at 70°C for 10 minutes;

[0040] Add 20 parts of chlorinated paraffin and 5 parts of antimony trioxide into the above mixture, heat to 80°C, and stir until no solid particles appear; then add 9 parts of diethylenetriamine-propylene oxide phenyl ether adduct , stir well;

[0041] Put the prepared material liquid under vacuum (vacuum degree is 9.5*10 4 Pa) Stirring, the stirring speed is 180r / min, degassing for 12 minutes; then the degassed material is placed in a molding mold for curing, and it is released after 3.5 hours, and the mold temperature is 90°C;

[0042] Then, the above-mentioned board after release was kept at a constant temperature of 55° C. for 2 hours. The obtained plates were processed into test specimens according ...

Embodiment 2

[0044] Add 100 parts of epoxy resin, 14 parts of dibutyl phthalate, 8 parts of nitrile rubber, 80 parts of glass fiber, 20 parts of calcium carbonate, and 12 parts of allyl glycidyl ether into the reactor according to the formula ratio. Stir at 75°C for 8 minutes;

[0045] Add 15 parts of decabromodiphenyl ether and 6 parts of zinc borate into the above mixture, heat to 85°C, and stir until no solid particles appear; then add 5 parts of 2-methylimidazole, and stir to mix;

[0046] Put the prepared material liquid under vacuum (vacuum degree is 9.2*10 4 Pa) Stirring at a stirring speed of 170r / min, degassing for 10 minutes; then placing the degassed material in a molding mold for curing, and releasing it after 3 hours, and the mold temperature is 80°C;

[0047] Then, the above-mentioned board after release was kept at a constant temperature of 60° C. for 1.5 hours. The obtained plates were processed into test specimens according to the standard experimental requirements, and ...

Embodiment 3

[0049] Add 100 parts of epoxy resin, 6 parts of dinonyl phthalate, 4 parts of EPDM rubber, 120 parts of glass fiber, 60 parts of calcium carbonate, and 8 parts of allyl glycidyl ether into the reaction kettle according to the formula ratio , stirred at 80°C for 8 minutes;

[0050] Add 20 parts of tetrabromobisphenol A and 6 parts of antimony trioxide into the above mixture, heat to 95°C, and stir until no solid particles appear; then add 10 parts of diethylenetriamine-propylene oxide phenyl ether adduct portion, stir well;

[0051] Put the prepared material liquid under vacuum (vacuum degree is 10.0*10 4 Pa) Stirring at a stirring speed of 160r / min, degassing for 14 minutes; then placing the degassed material in a molding mold for curing, and releasing it after 3 hours, and the mold temperature is 100°C;

[0052] Then, the above-mentioned board after release was kept at a temperature of 65° C. for 2 hours at a constant temperature. The obtained plates were processed into te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com