Novel ion exchange fiber and its application

An ion exchange fiber, a new technology, applied in ion exchange, anion exchange, fiber type, etc., can solve the problems of performance not meeting the use requirements, little application value, poor solvent resistance, etc., achieve good mechanical properties and short regeneration time , the effect of high adsorption value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

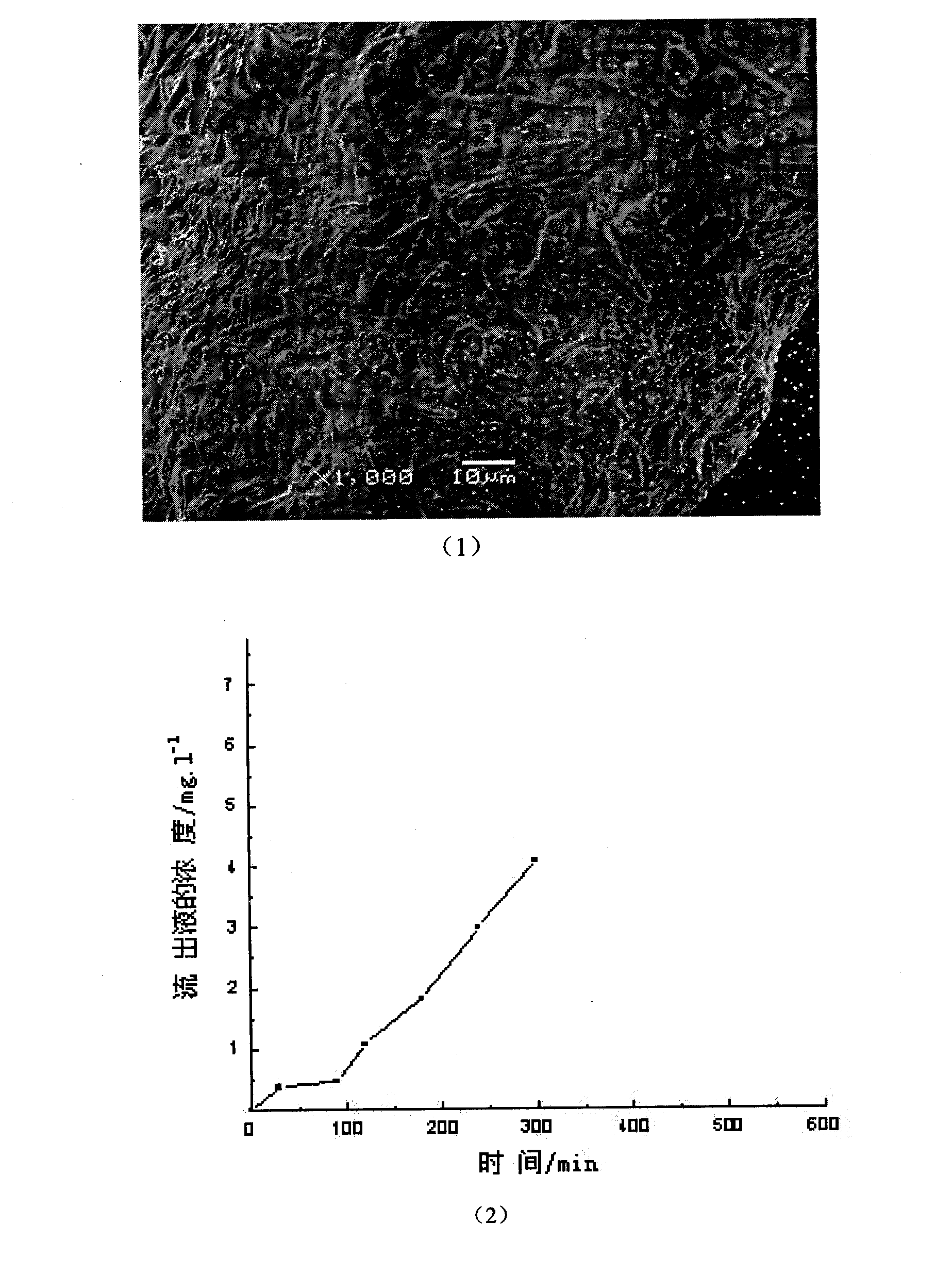

Image

Examples

Embodiment 1

[0033] Matrix fiber preparation:

[0034] The raw materials PS, PE and compatibilizer are mixed according to a certain weight ratio and fed into the feeding port of the spinning machine, and the spinning is carried out at a temperature of 180-230°C. The fiber is drawn through godet rollers and godet rollers, and wound onto a winder for winding. The parts by weight of the compatibilizer are 1; the total parts by weight of PS and PE are 99; the weight ratio of PS and PE is 90:10;

[0035] The PS has a molecular weight of 100,000 and a melt index of 12g / 10min;

[0036] The PE has a molecular weight of 120,000 and a melt index of 15g / 10min;

[0037] The compatibilizer is SIS;

[0038] Unwind the fiber from the winder for post-stretching. The process conditions for stretching are 90°C temperature and 0.5 times the draw ratio.

[0039] Preparation of ion exchange fibers:

[0040] The base fiber is washed with ethanol or acetone to remove oil stains, and after vacuum drying, the...

Embodiment 2

[0045] Matrix fiber preparation:

[0046] The raw materials PS, PE and compatibilizer are mixed according to a certain weight ratio and fed into the feeding port of the spinning machine, and the spinning is carried out at a temperature of 180-230°C. The fiber is drawn through godet rollers and godet rollers, and wound onto a winder for winding. The weight part of compatibilizer is 0.5; the total weight part of PS and PE is 99.5; the weight ratio of PS and PE is 60:40

[0047] The PS has a molecular weight of 200,000 and a melt index of 8g / 10min;

[0048] The PE has a molecular weight of 80,000 and a melt index of 18g / 10min;

[0049] The compatibilizer is SBS;

[0050] Unwind the fiber from the winder for post-stretching. The process conditions for stretching are 110° C. temperature and 3 times the stretching ratio.

[0051] Preparation of ion exchange fibers:

[0052] The base fiber is washed with ethanol or acetone to remove oil stains, and after vacuum drying, the base ...

Embodiment 3

[0057] Matrix fiber preparation:

[0058] The raw materials PS, PE and compatibilizer are mixed according to a certain weight ratio and fed into the feeding port of the spinning machine, and the spinning is carried out at a temperature of 180-230°C. The fiber is drawn through godet rollers and godet rollers, and wound onto a winder for winding. The parts by weight of compatibilizer are 5; the total parts by weight of PS and PE are 95; the weight ratio of PS and PE is 80:20

[0059] The PS has a molecular weight of 50,000 and a melt index of 24g / 10min;

[0060] The PE has a molecular weight of 100,000 and a melt index of 16g / 10min;

[0061] The compatibilizer is SEEPS;

[0062] The fiber is withdrawn from the winding machine for post-stretching. The process conditions for stretching are 100° C. temperature and 2 times the stretching ratio.

[0063] Preparation of ion exchange fibers:

[0064] Cleaning the base fiber with ethanol or acetone to remove oil stains, vacuum dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com