Preparation of microcapsules of viable microbe biopesticide

A technology of microcapsules and biopesticides, applied in the fields of biopesticides and biochemistry, can solve the problems of easy inactivation of bacterial strains and no technical reports on production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0012] 1. Selection of microbial strains

[0013] Select Bacillus subtilis to inoculate in 50mL / 250mL SDAY seed medium, and cultivate it at 35°C and 150r / min for about 18h (measure the OD with a UV spectrophotometer). 600 6.0), inoculated into the fermentation medium of an optimized 50L fermenter, and cultured at 30°C for 48h to obtain a fermentation broth.

[0014] 2. Preparation of oil-water affinity emulsifier:

[0015] The HLB value is a measure of the relative value of the emulsifier's lipophilicity and hydrophilicity. The larger the value, the stronger the hydrophilicity. Every emulsification system requires an appropriate lipophilic-hydrophilic group ratio (HLB value). The HLB value of the emulsifier determines different emulsification effects. How to choose the HLB value of the compound emulsifier in the oil-water system to obtain the best emulsion is the key to the emulsification process. In the present invention, Span 80 and Tween 80 are formulated into an oil-wat...

Embodiment approach 2

[0045] In this scheme, firstly, the carrier absorbs the bacteria as the capsule core of the microcapsule, and then obtains the sodium alginate microcapsule by the emulsification method. The microcapsule preparation process is as follows: sodium alginate is dissolved in water to prepare a sodium alginate solution. Add the capsule core to the sodium alginate solution, stir evenly, then add the sodium alginate capsule core mixture to the oil under stirring, after stirring to disperse, add the calcium chloride solution, stir and solidify, stand still, filter and wash ,dry.

[0046] 1. Strain preparation

[0047] Pseudomonas fluorescens was inoculated into the optimized 50mL / 250mL fermentation medium, and cultured on a shaker at 37°C and 150r / min for 12h to obtain a seed culture solution. Then culture in a 50L fermenter for 48 hours to obtain a microbial fermentation liquid.

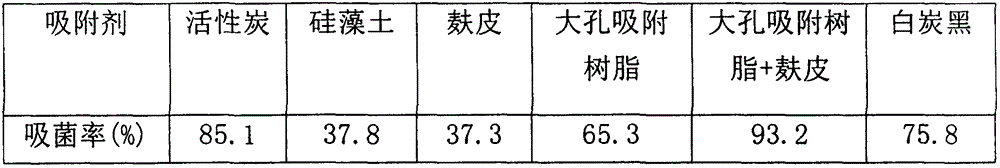

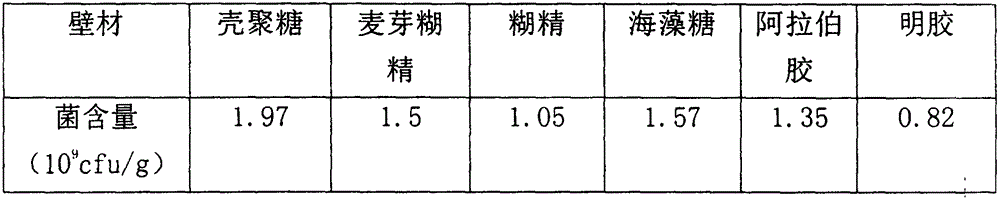

[0048] 2. Capsule core preparation

[0049] Take 10 liters of fermentation broth, add adsorption carri...

Embodiment approach 3

[0069] 1. Select Bacillus subtilis and inoculate it into the optimized 50mL / 250mL fermentation medium, and culture it on a shaker at 35°C and 150r / min for 12h to obtain a seed culture solution. Then culture in a 50L fermenter for 48 hours to obtain a microbial fermentation liquid.

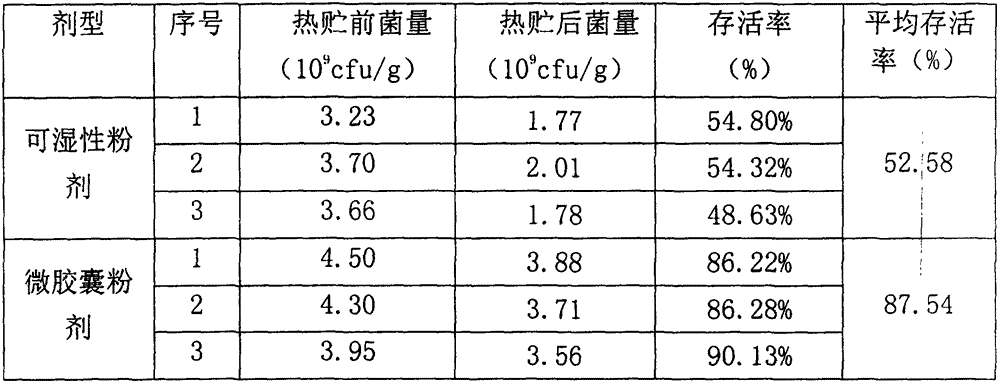

[0070] 2. Using the adsorbent and oil-water affinity emulsifier prepared in Example 2, add 300g of adsorbent activated carbon to the Bacillus subtilis fermentation broth at a rate of 300g per 10L of fermentation broth, stir for 20min, and then let stand for 10min. The mixed solution was filtered to remove moisture from the fermentation broth, and the obtained activated carbon was dried in a blast dryer at 37° C. for 5 hours. Mix 500 grams of activated carbon for adsorbing bacteria into 1 L of soybean oil, and stir evenly to prepare a mixture of bacteria, adsorbent and oil. Add this mixed solution at a uniform speed to 1 liter of chitosan wall material solution containing 2% stirred at a medium spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com