Heat exchanger

A technology for heat exchangers and heat exchange tubes, which is applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., and can solve the problems of reducing the space utilization rate of tubular shells, difficulties in large-scale and popularization and application, and heat exchange problems. Reduce the compactness of the device and other problems, and achieve the effect of improving energy dissipation, easy perforation operation, and reducing the thickness of the bottom laminar flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

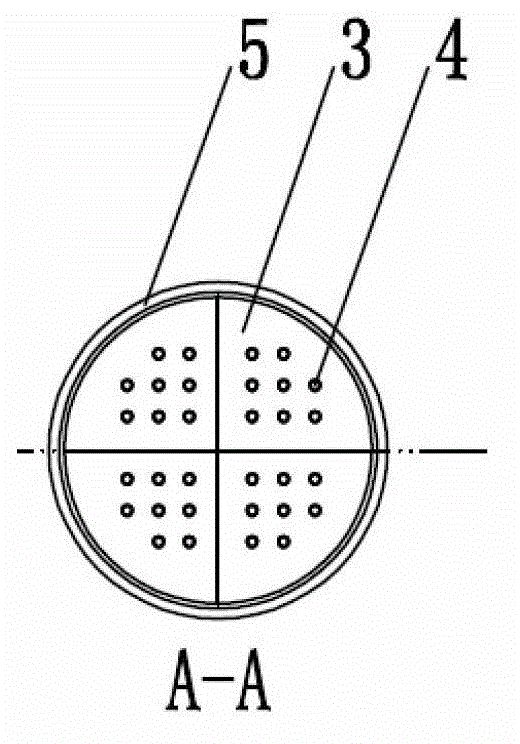

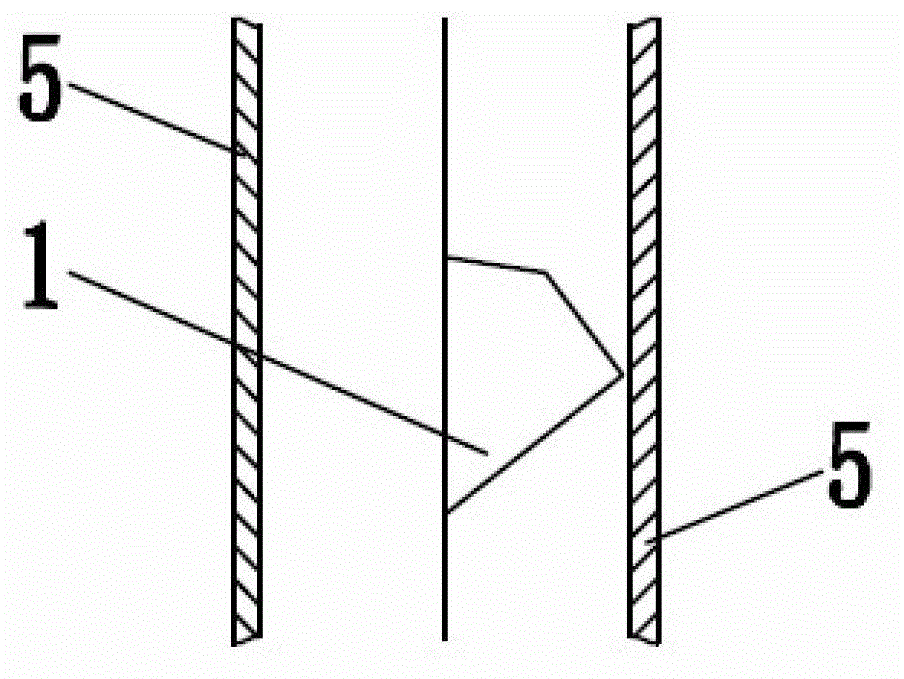

[0051] Such as figure 1 and figure 2 , a schematic diagram of the overall structure of a double-channel heat exchanger in a fully-enclosed channel continuous spiral baffle heat exchanger with an axial support plate structure includes: a tubular shell 5 with twelve supports 2 inside, and supports 2 Rotate one side of the coaxial side on a plane with α=180° fixedly connected by two support plates to form a support 2 with a rhombus structure, in which the support 2 at both ends is 1 / 2 each, and all the supports end to end Then rotate the adjacent supports 2 at an angle of β=90° according to the right-handed spiral method, and then use the baffles 3 to rotate the 24 baffles 3 on both sides of the two adjacent supports according to the right-handed spiral method. Corner closed fixed connection, a number of heat exchange tubes pass through the through holes on the baffle, and then through the limit inlays 12 at both ends and the vertical fixed connection of the tube plate 7, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com