Oil filling pipe assembly for engine

A technology for oil pipes and engines, which is used in lubricant conduit devices, adding/discharging lubricants, and lubricating parts, etc., can solve the problems of cumbersome strength reliability judgment, long development cycle of new products, and many welding parts, etc., to avoid High failure risk, lightweight and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

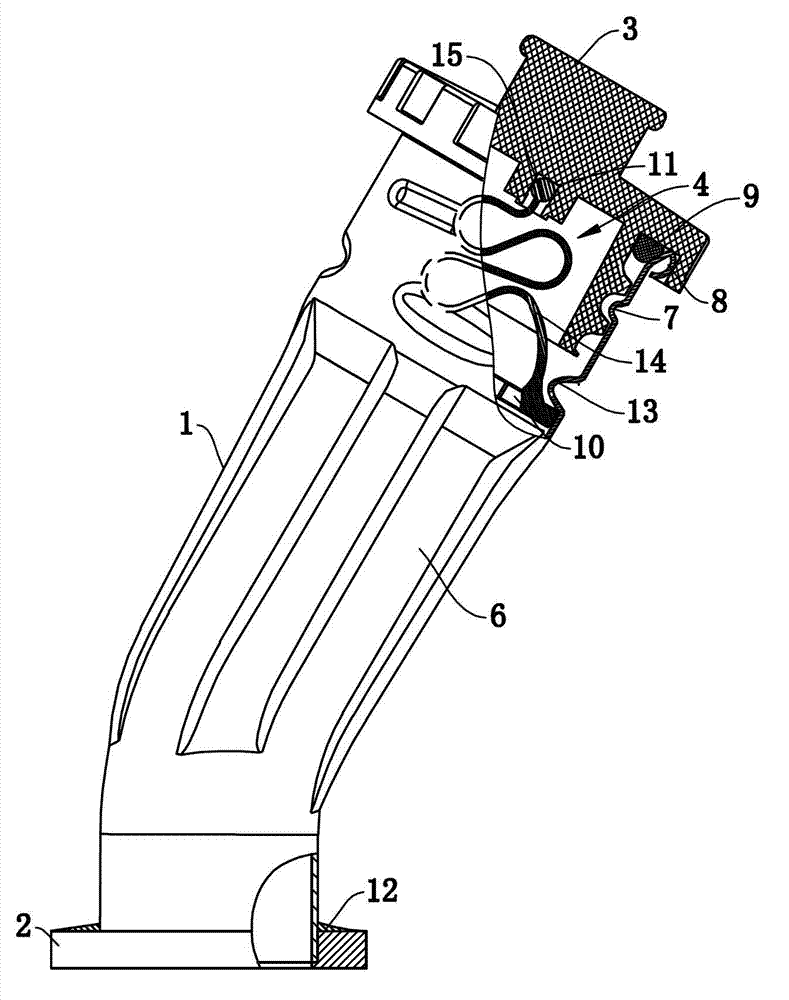

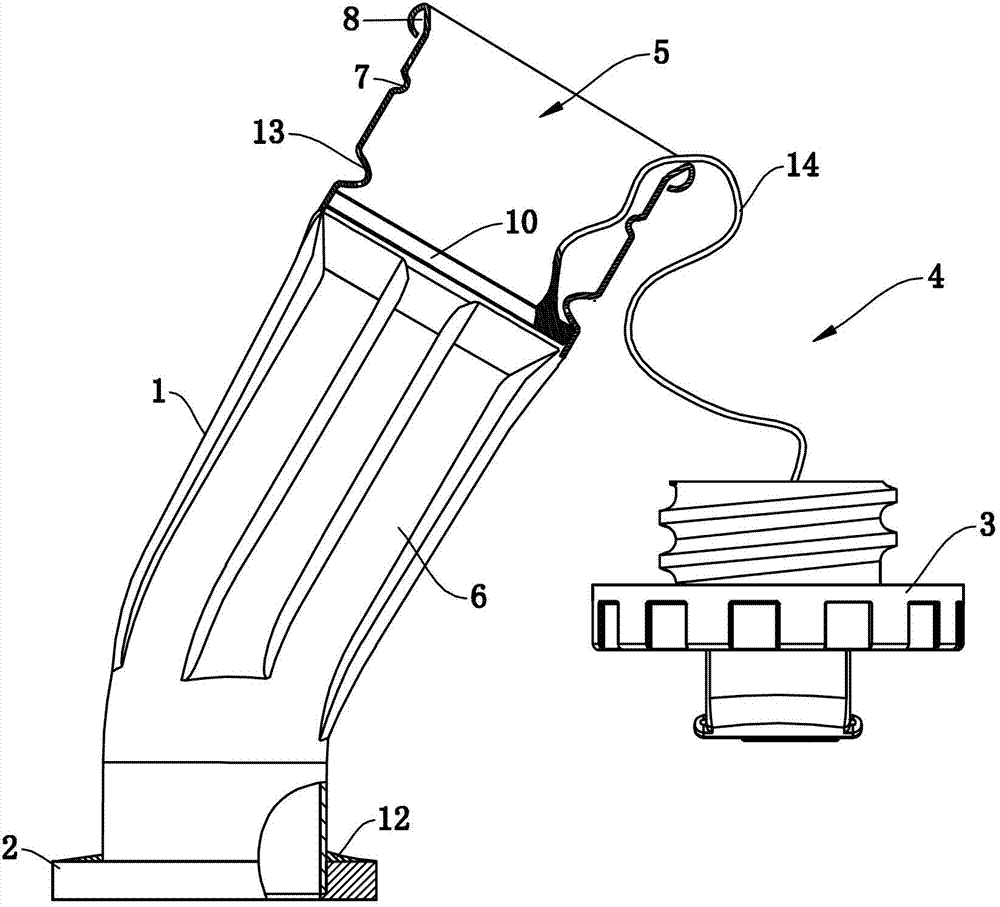

[0025] Such as figure 1 and figure 2 Commonly shown, the engine oil pipe assembly includes the oil pipe body 1, the flange 2, the pipe cover 3 and the connecting part 4. One end of the oil pipe body 1 is provided with a nozzle 5, and the other end of the oil pipe body 1 is connected to the flange 2. The nozzle and the cap 3 are connected by threads, and the oil pipe body 1 and the cap 3 are connected by a connecting part 4. The oil pipe body 1 is a thin-walled stainless steel pipe processed by hydroforming, and the wall thickness of the thin-walled stainless steel pipe is 0.5mm-1mm. The pipe wall of the tubing body 1 is provided with four concave-convex reinforcing ribs 6, and the concave-convex reinforcing ribs 6 improve the strength of the tubing body 1, so that under the condition of satisfying the same structural strength as that of the prior art...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com