Preparation method for carbon nanomaterial enhanced aluminum base composite material

A nano-carbon material, a technology for reinforcing aluminum matrix, which is applied in the preparation of composite materials and the field of preparation of nano-carbon material reinforced aluminum matrix composite materials, can solve problems such as precise requirements, save costs, improve mechanical properties, and achieve high density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

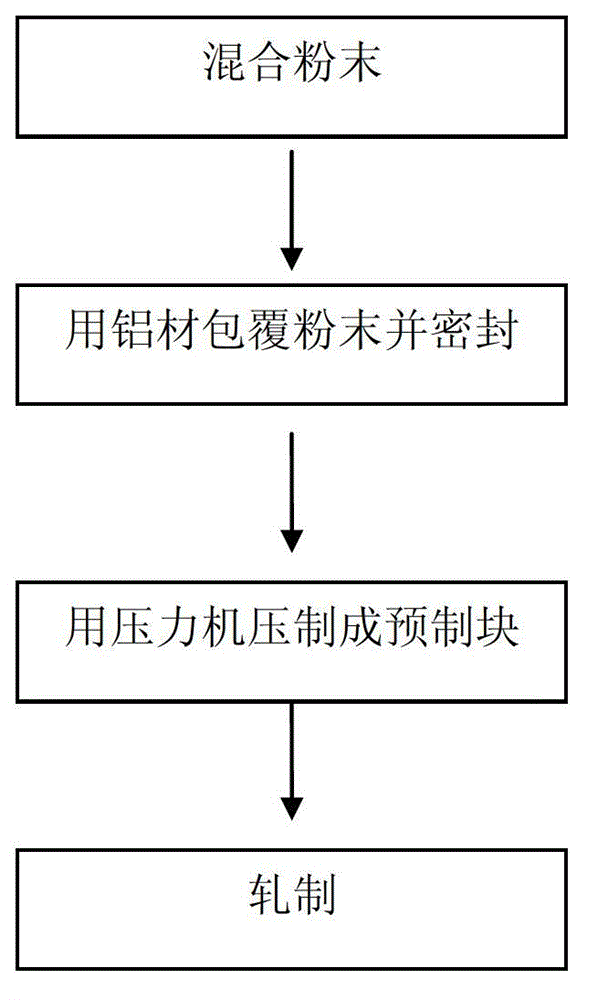

Method used

Image

Examples

Embodiment 1

[0036] Weigh 100g of pure aluminum powder (200 mesh particle size) and 1g of graphene, mix thoroughly with a ball mill and put them into the cleaned aluminum tube, compact the mixed powder in the aluminum tube and press the aluminum tube in two stages with a press Seal tightly. The sample is heated to 450°C, and the powder sample is pressed into a prefabricated block with a certain density by a press. The obtained prefabricated block was sintered for 1 hour under the protective environment of argon, and then hot-rolled, and the sintering temperature was 550°C. The tensile strength of the obtained experimental sample at room temperature reaches 142MPa, and the Vickers hardness is about 41kg / mm 2 .

Embodiment 2

[0038] Weigh 100g of pure aluminum powder (with a particle size of 200 mesh) and 5g of copper-coated graphene, mix them thoroughly with a ball mill, put them into a cleaned aluminum tube, compact the mixed powder in the aluminum tube, and use a press to double the aluminum tube. Segment compression seal. The sample is heated to 400°C, and the powder sample is pressed into a prefabricated block with a certain density by a press. The obtained precast was sintered for 1.5h under the protective environment of block argon, and then hot-rolled, and the sintering temperature was 500°C. The tensile strength of the obtained experimental sample at room temperature reaches 160MPa, and the Vickers hardness is about 50kg / mm 2 .

Embodiment 3

[0040] Weigh 100g of pure aluminum powder (with a particle size of 200 mesh) and 3g of copper-coated graphene, mix them thoroughly with a ball mill, put them into a cleaned aluminum tube, compact the mixed powder in the aluminum tube, and press the aluminum tube into two parts with a press. Segment compression seal. Then use a press for cold pressing, and the reduction of cold pressing deformation is greater than that of hot pressing deformation. After cold pressing, the obtained prefabricated blocks were sintered for 2 hours under the protective environment of argon, and then hot-rolled, and the sintering temperature was 550°C. The tensile strength of the obtained experimental sample at room temperature reaches 153MPa, and the Vickers hardness is about 42kg / mm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com