Combined hydrogenation method

A catalytic hydrogenation and jet fuel technology, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, can solve the problems of low-concentration hydrogen loss, low temperature, unfavorable device heat utilization, etc., and achieve the change of gas-liquid The effect of balancing coefficient, increasing feed temperature, and improving deodorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

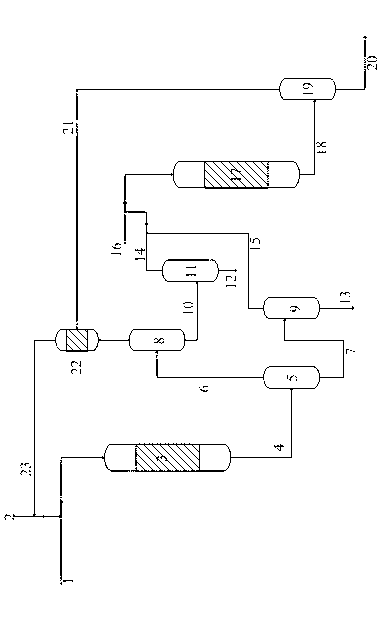

[0021] The method and effect of the present invention will be further described below through the combined process of straight-run jet fuel hydrogenation deodorization device and diesel fraction hydrotreating.

[0022] See Table 1-1 for the straight-run jet fuel raw materials used, and Table 1-2 for the diesel raw materials. The catalyst is FH-UDS hydrotreating catalyst developed and produced by Fushun Petrochemical Research Institute (see Table 1-3 for main property indicators).

[0023] Table 1-1 Main properties of straight-run jet fuel raw materials.

[0024] Oil properties Straight run jet fuel raw material Density(20℃) / g.cm -3 0.7876 Distillation range / ℃ IBP / EBP 146 / 231 Sulfur / μg.g -1 1258 PhD test Mercaptan sulfur / μg.g -1 99.7

[0025] Table 1-2 Main properties of diesel raw materials.

[0026] project Diesel feedstock Density, g / cm 3 0.8486 Distillation range (ASTM D86), ℃ Distillation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com