Automatic control sewage treatment system with variable process and treating capacity

A sewage treatment system and sewage treatment technology, applied in the direction of sterilization/microdynamic water/sewage treatment, biological water/sewage treatment, adsorbed water/sewage treatment, etc. , investment costs and land area increase, automatic monitoring and control still need to be improved and other issues, to achieve the effect of saving processing time, reducing operating costs, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

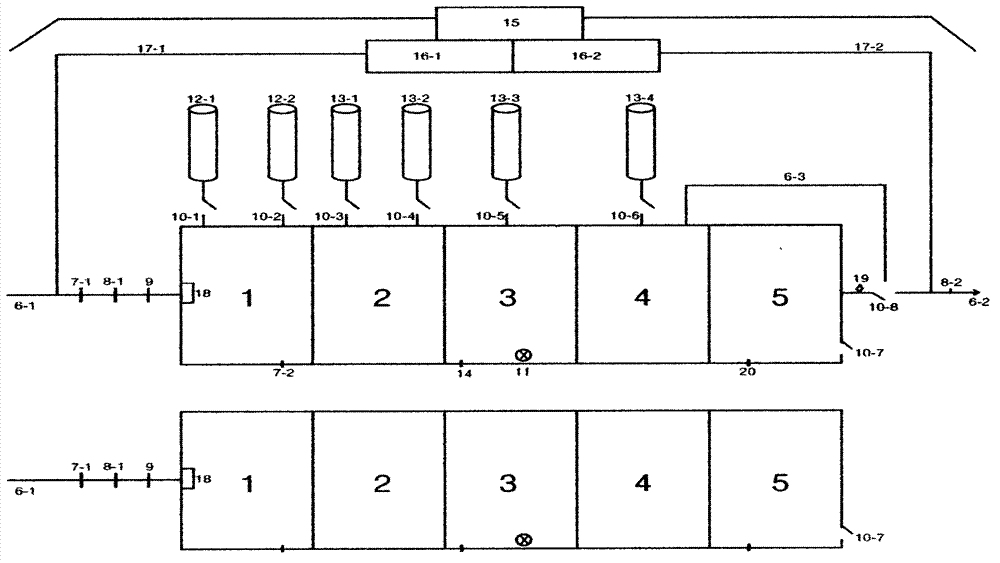

[0009] Install an ultrasonic flowmeter 8-1 on the water inlet pipe 6-1 of the sewage treatment tank to monitor the sewage flow, install a pH online monitor sensor head 7-1 to measure the pH value, and install an online suspended solids S S tester 9 to measure Suspended matter S S, connect the fine water pipe 1 7-1 to the water sample pool 1 6-1 in the control room, measure the chemical oxygen demand COD of the sewage with an automatic analyzer and a spectrophotometer, and record it.

[0010] Sewage is installed on the pool wall at the entrance of the regulating pool 1 with multiple rows of semi-circular pin headers 18. Its structure is: a gear with a diameter of about 40 cm, the shaft of which is inserted into the pool wall and fixed, the gear is driven by the motor to rotate, the gear is equipped with a toothed chain to engage with it, the chain is welded with a fixed bracket, and the bracket is drilled with screw holes , insert the half-round pin header into the screw hole a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com