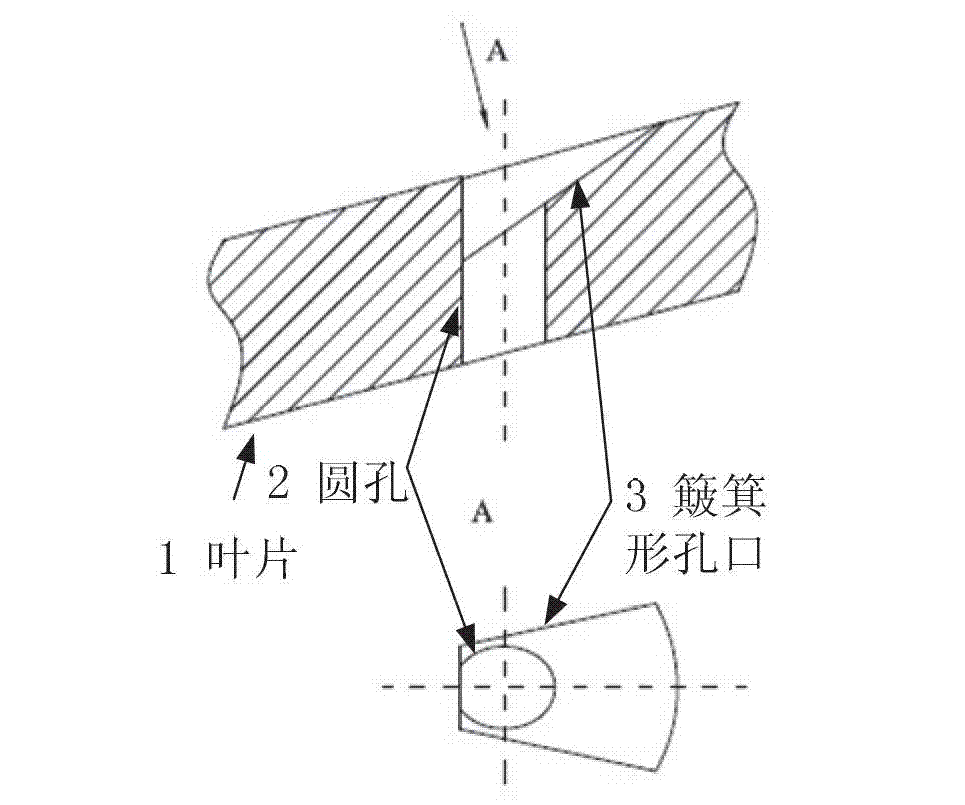

Machining method of gravity-free smelting layer air membrane hole of aviation engine turbine blade

A technology for aero-engine and turbine blades, which is applied in the processing field of aero-engine turbine blades without remelting layer gas film holes, can solve the problems of electrode wear, frequent electrode replacement, and long electrode manufacturing time, and achieves reduction of manufacturing cycle and reduction. The difficulty of electrode manufacturing and the effect of improving surface processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

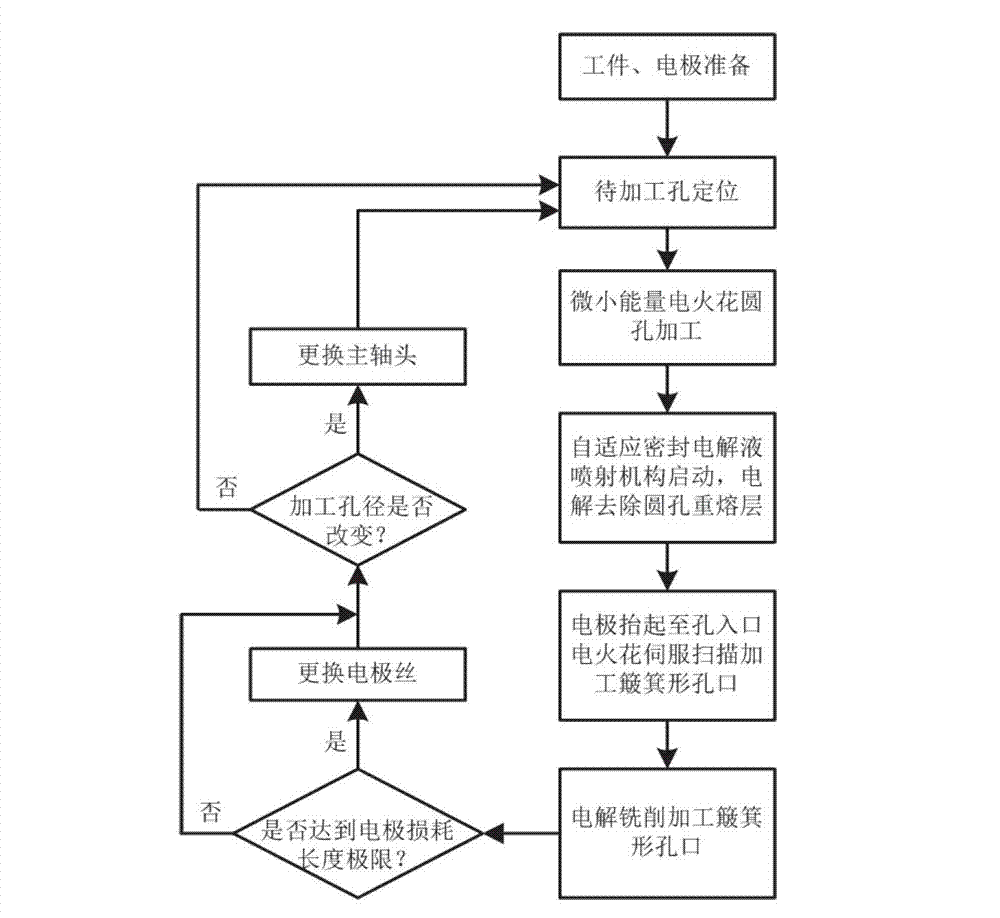

[0036] According to the processing position and shape requirements of the air film hole of the blade, the blade is clamped and positioned by the tenon of the blade, and the hole to be processed is adjusted to the station through the five axes of X, Y, Z, A, B, and the hollow hole with an outer diameter of 0.38 mm The electrode wire is clamped by the spindle head and adjusted to the required position of the hole to be processed by the machine tool.

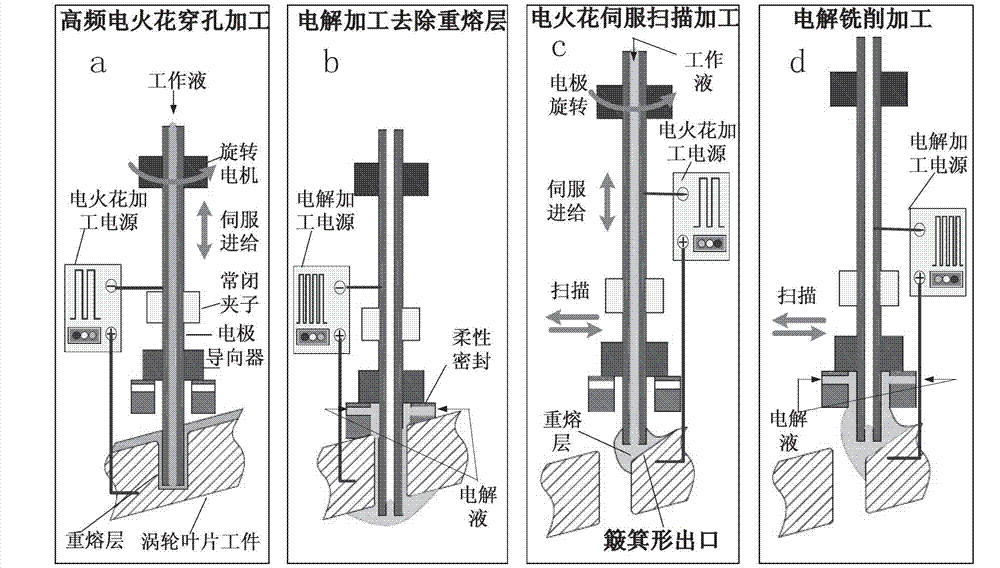

[0037] like figure 2 As shown in a, start the high-frequency narrow pulse width pulse power supply, the electrode rotating motor, and the high-pressure water pump for flushing liquid in the electrode. By detecting the discharge state, use the normally open and normally closed clamps at the lower end of the electrode to clamp the electrode and perform servo control. To, realize EDM round hole machining. By detecting the change of current and voltage when the electrode penetrates the exit of the hole to be processed from liquid dis...

Embodiment 2

[0043] According to the processing position and shape requirements of the air film hole of the blade, the blade is clamped and positioned by the tenon of the blade, and the hole to be processed is adjusted to the station through the five axes of X, Y, Z, A, B, and the hollow electrode with an outer diameter of 0.38 mm The wire is clamped by the spindle head and adjusted to the required position of the hole to be processed by the machine tool.

[0044] like figure 2 As shown in a, start the high-frequency narrow pulse width pulse power supply, the electrode rotating motor, and the high-pressure water pump for flushing liquid in the electrode. By detecting the discharge state, use the normally open and normally closed clamps at the lower end of the electrode to clamp the electrode and perform servo control. To, realize EDM round hole machining. By detecting the change of current and voltage when the electrode penetrates the exit of the hole to be processed from liquid discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com