Mechanical laying method for large-section overhead cable

An overhead cable and cable laying technology, applied in the direction of overhead lines/cable equipment, cable laying equipment, etc., can solve the problems of laborious lifting, low efficiency, high cost, etc., and achieve the effect of reducing the risk of accidents and avoiding dangerous factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

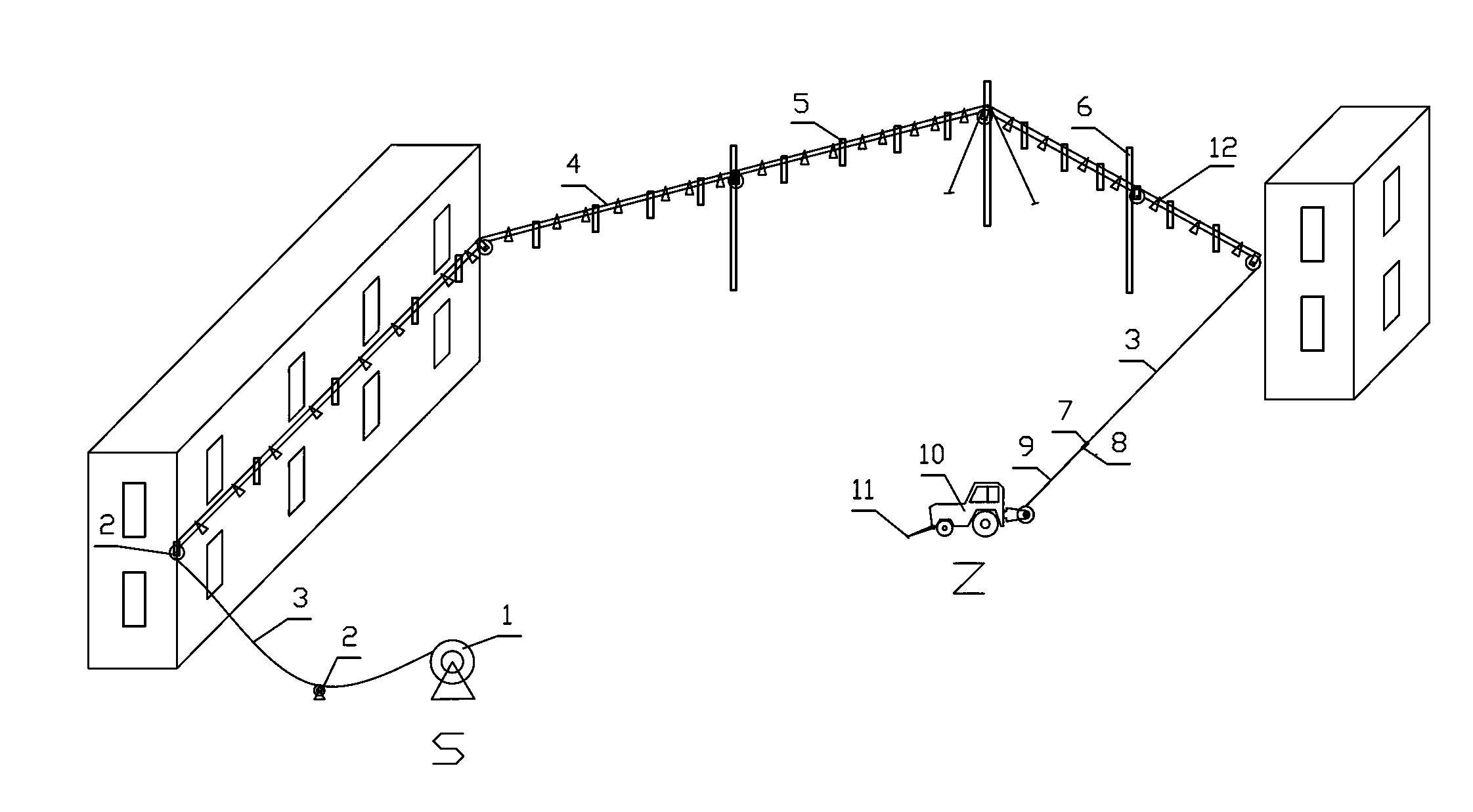

[0029] like figure 1 As shown, before laying the cable, install the cable pulley 2 for guiding at each corner of the line, and lay out the non-twisted braided traction wire rope 9 along the laying line; use the operating rod to install and penetrate the non-twist The gravity self-locking cable suspension tackle 5 of the twisted braided traction wire rope 9, the guide cable tackle 2 of the non-twisted braided traction wire rope 9 is installed as required near the cable laying terminal point Z. At the end point Z of the laying line, use structures or install ground anchors 11 to fix the traction machine 10, and at the starting point S of the laying line, set up the cable reel 1; install the cable pulling head on the end of the large-section cable 3 to be laid Or the cable netting 7, the pulling head or the cable netting 7 is connected with the untwisted braided t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com