Novel flux for ZK60 magnesium alloy, and preparation method and usage method thereof

A ZK60 and magnesium alloy technology, applied in the field of alloy smelting, can solve the problems of rising prices, restricting the development and application of alloys, and high costs, and achieve the effects of increasing yield, controlling smelting costs, and saving zirconium resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

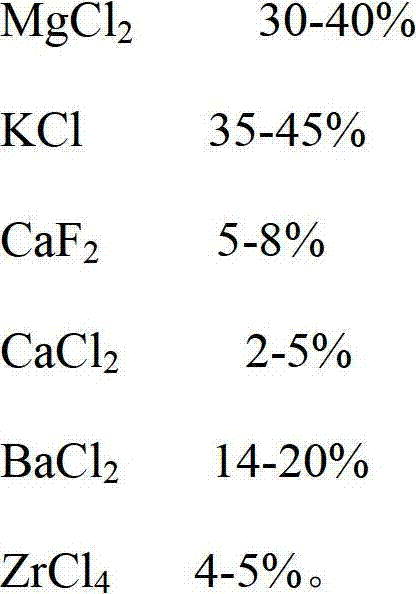

[0012] The new flux used for ZK60 type magnesium alloy is composed of the following raw materials in mass percentage:

[0013]

[0014] The preparation method of the new flux used for ZK60 type magnesium alloy is to first add CaCl 2 and BaCl 2 Heated to 400K for dehydration, then KCl, MgCl 2 , ZrCl 4 with dehydrated CaCl 2 and BaCl 2 Put them together in the crucible according to the proportion and heat to 1073K, stir evenly after the boiling stops, pour into blocks, break and mix with CaF 2 Grind them together into powder and use them after sieving.

[0015] The using method of the novel flux that ZK60 type magnesium alloy is used is that melt is heated to 1098-1103K and adds described novel flux to carry out refining, consumption is 20Kg / ton, stirs 30 minutes, the Zr element in the magnesium alloy receives in the present embodiment rate reached 72%.

Embodiment 2

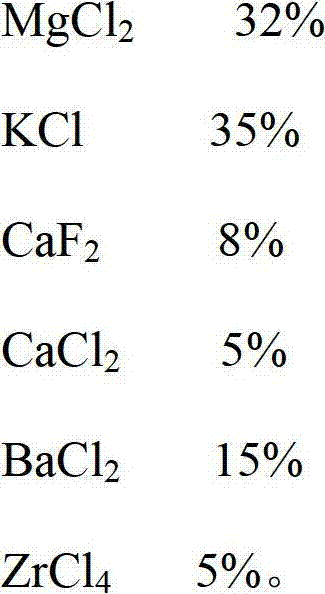

[0017] The novel flux used for Mg-Zn-Zr alloys consists of the following raw materials in mass percentages:

[0018]

[0019] The preparation method of the new flux used for ZK60 type magnesium alloy is to first add CaCl 2 and BaCl 2 Heated to 400K for dehydration, then KCl, MgCl 2 , ZrCl 4 with dehydrated CaCl 2 and BaCl 2 Put them together in the crucible according to the proportion and heat to 1073K, stir evenly after the boiling stops, pour into blocks, break and mix with CaF 2 Grind them together into powder and use them after sieving.

[0020] The using method of the novel flux that ZK60 type magnesium alloy is used is that melt is heated to 1098-1103K and adds described novel flux to carry out refining, consumption is 20Kg / ton, stirs 30 minutes, the Zr element in the magnesium alloy receives in the present embodiment rate reached 75%.

Embodiment 3

[0022] The novel flux used for ZK60 type magnesium alloy is characterized in that it consists of the following raw materials in mass percentage:

[0023]

[0024] The preparation method of the new flux used for ZK60 type magnesium alloy is to first add CaCl 2 and BaCl 2 Heated to 400K for dehydration, then KCl, MgCl 2 , ZrCl 4 with dehydrated CaCl 2 and BaCl 2 Put them together in the crucible according to the proportion and heat to 1073K, stir evenly after the boiling stops, pour into blocks, break and mix with CaF 2 Grind them together into powder and use them after sieving.

[0025] The using method of the novel flux that ZK60 type magnesium alloy is used is that melt is heated to 1098-1103K and adds described novel flux to carry out refining, consumption is 20Kg / ton, stirs 30 minutes, the Zr element in the magnesium alloy receives in the present embodiment rate reached 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com