Direct reduction process for producing spongy iron from CH4-rich coal gas

A technology of sponge iron and coal gas, applied in the field of metallurgy, can solve problems such as reducing emissions, achieve the effects of reducing fuel gas consumption, preventing sponge iron from sticking, and reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

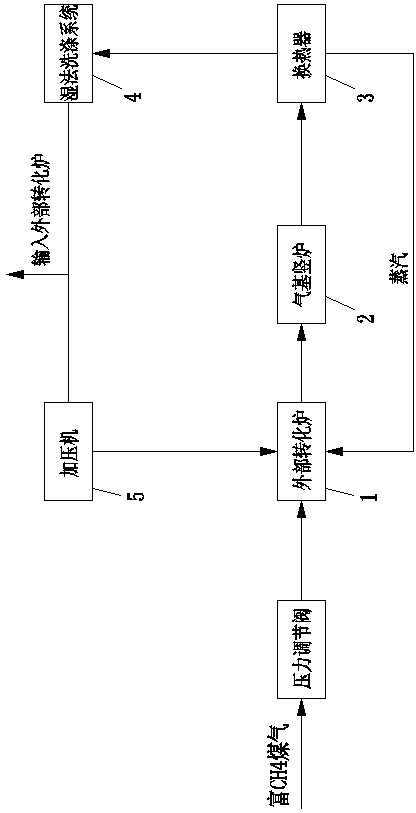

[0022] As shown, this embodiment utilizes rich CH 4 The direct reduction process of coal gas production sponge iron comprises the following steps:

[0023] Include the following steps:

[0024] a, the pressure-regulated rich CH 4 Coal gas and gas-based shaft furnace top gas that have been treated in turn by cooling, dust removal, and pressurization are input into external reformer 1, and supplemented into external reformer 1 as CH 4 The steam of the reforming reaction oxidant occurs, so that the CH in the external reformer 1 4 、H 2 O and CO 2 Under the action of the catalyst, the modification reaction produces mainly CO and H 2 reduced gas;

[0025] b. The high-temperature reducing gas generated in the external reformer 1 is fed into the gas-based shaft furnace 2 to directly reduce iron ore to generate sponge iron.

[0026] This example utilizes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com