Chitosanase producing strain and chitosan production method by using the same

A technology for producing chitosanase and strains, which is applied in the field of bioengineering, can solve the problems of not fundamentally reducing the production cost of chitosan oligosaccharide, and the process of breaking cells is complicated and reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

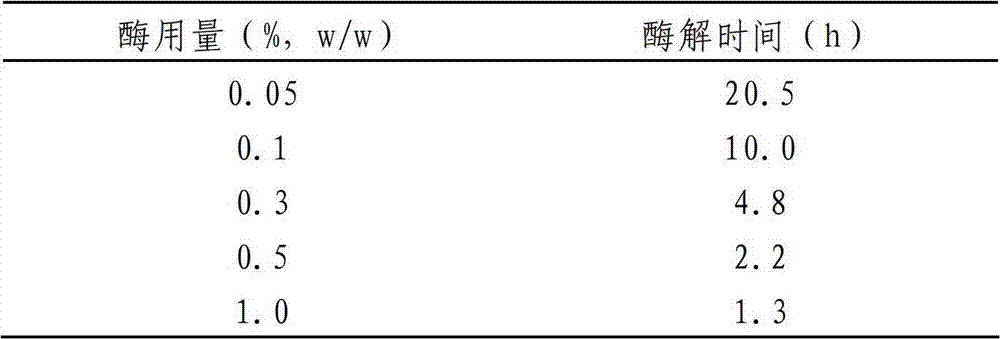

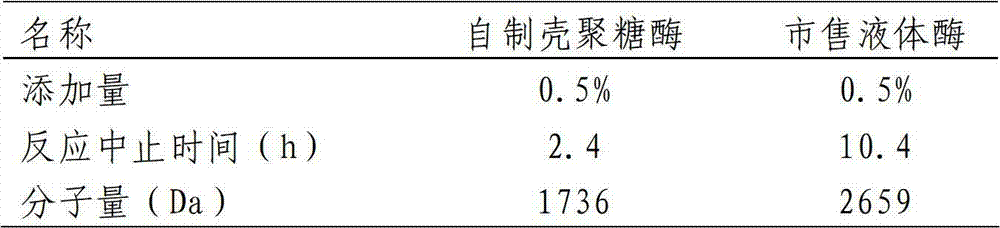

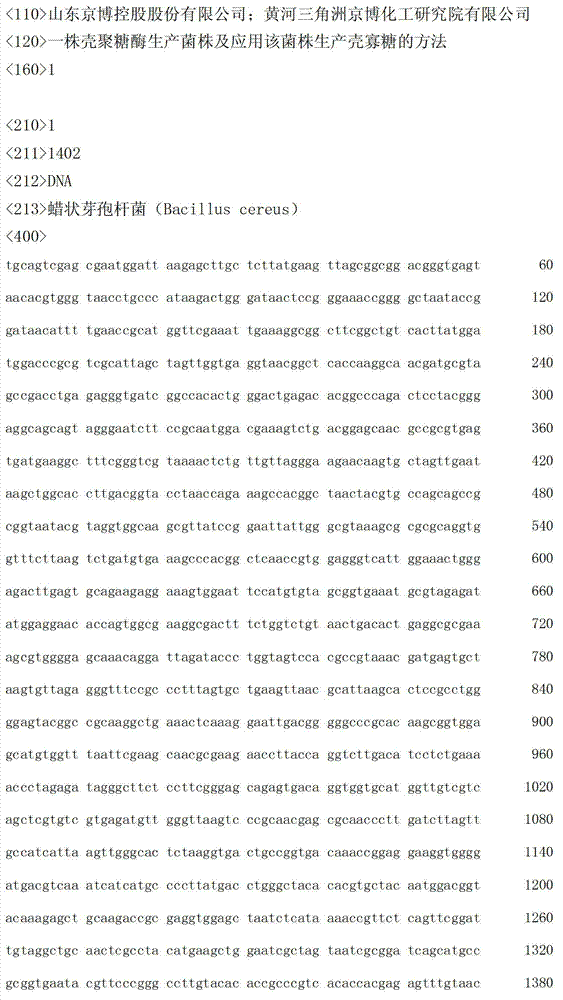

Method used

Image

Examples

Embodiment 1

[0069] liquid seed culture

[0070] The composition of seed medium (w / w) is: beef extract 2%, yeast powder 0.5%, glucose 2%, ammonium sulfate 0.5%, soybean meal 3%, corn flour 3%, and the balance is water; initial pH value is natural; 121 ℃, sterilize at 0.15Mpa for 20min.

[0071] Seed culture conditions: under aseptic conditions, rinse the activated CGMCC No.6129 test-tube slanted strains into a conical flask containing sterilized liquid medium with 10 mL of sterilized distilled water, and inoculate one inoculated with one test-tube strain Erlenmeyer flask, culture temperature 33~35℃, shaker speed 150r / min, culture time 12~18h;

Embodiment 2

[0073] solid fermentation

[0074] Composition of solid fermentation medium (w / w): 70% bran, 15% soybean meal, 13% corn meal, 2% ammonium sulfate; the ratio of material to water is 1:1.1; the initial pH value is natural; the culture temperature is 33 °C, and the fermentation The time is 48h; every 15h, the song is turned over.

[0075] After the fermentation is completed, it is dried at 55°C, pulverized, and passed through an 80-mesh sieve, which is the crude chitosanase enzyme. Samples were taken and the enzyme activity was detected by DNS method, and the average enzyme activity was 2547U / g.

Embodiment 3

[0077] solid fermentation

[0078] Composition of solid fermentation medium (w / w): 80% bran, 10% soybean meal, 7% corn meal, 3% ammonium sulfate; the ratio of material to water is 1:1.15; the initial pH value is natural; the cultivation temperature is 33~35℃ , the fermentation time is 48h; it is turned every 15h.

[0079] After the fermentation was completed, it was dried at 50°C, crushed, and sieved to obtain the crude chitosanase enzyme. The chitosanase activity was sampled and detected, and the average enzyme activity was 2732 U / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com