Anti-dropping flame-retardant ABS material and preparation method thereof

An ABS material and anti-drop technology, which is applied in the field of anti-drop flame-retardant ABS material and its preparation, can solve problems such as difficult high-altitude drop testing and failure to meet customer requirements well, and achieve excellent comprehensive performance and good mechanical properties , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

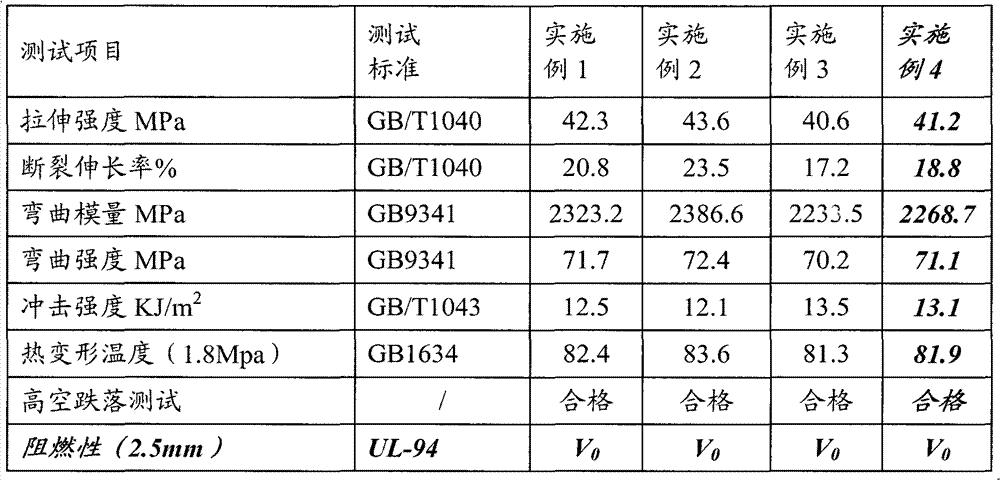

Examples

preparation example Construction

[0029] The present invention also provides a method for preparing an anti-drop flame retardant ABS material, which comprises the following steps:

[0030] a. Weigh each component according to the above mass percentage, specifically, ABS resin: 70-80%; toughening agent: 2-6%; composite flame retardant: 18-25%; antioxidant: 0.2- 0.6%; processing aid: 0.3-1%; anti-dripping agent: 0.1-0.3%, and mix the weighed components in a high-speed mixer and stir for 2-5 minutes;

[0031] b. Add the homogeneously mixed material in step a into the hopper of the twin-screw extruder, melt, blend and extrude through the high-temperature extruder, cool, air-dry, and granulate;

[0032] Among them, the temperature of each heating zone of the twin-screw extruder is respectively set as follows: first zone temperature: 180-190°C; second zone temperature: 185-195°C; third zone temperature: 190-200°C; fourth zone temperature: 200 ~210℃; temperature in zone five: 200~210℃; temperature in zone six: 200~2...

Embodiment 1

[0036] Weigh acrylonitrile-butadiene-styrene copolymer (ABS)--77.3kg, styrene triblock copolymer (SBS)--4kg, composite flame retardant--18kg (bromotriazine--14kg , Sb 2 o 3 --4kg), antioxidant --0.3kg (main antioxidant 1010--0.2kg, secondary antioxidant 168--0.1kg), ethylene bisstearic acid amide (EBS) --0.3kg, containing Polytetrafluoroethylene (PTFE) - 0.1kg.

[0037]Then mix for 3 minutes in a high speed mixer. Then add the mixed material into the hopper of the twin-screw extruder, and control the temperature of each section: Zone 1: 185°C; Zone 2: 185°C; Zone 3: 195°C; Zone 4: 195°C; Zone 5 : 200°C; Sixth zone: 195°C; Seventh zone: 190°C; Eighth zone: 185°C; Machine head temperature: 180°C; Screw speed 400r / min, after melt blending extrusion, water cooling, air drying, pelletizing, drying Dry, and finally packaged into bags to obtain anti-drop flame-retardant ABS material.

Embodiment 2

[0039] Weigh acrylonitrile-butadiene-styrene copolymer (ABS)--74.3kg, styrene triblock copolymer (SBS)--5kg, composite flame retardant--20kg (bromotriazine--15kg , Sb 2 o 3 --5kg), antioxidant --0.3kg (primary antioxidant 1010--0.2kg, secondary antioxidant 168--0.1kg), ethylene bisstearic acid amide (EBS) --0.3kg, containing Polytetrafluoroethylene (PTFE) - 0.1kg.

[0040] Then mix for 3 minutes in a high speed mixer. Then add the mixed material into the hopper of the twin-screw extruder, and control the temperature of each section: Zone 1: 185°C; Zone 2: 185°C; Zone 3: 195°C; Zone 4: 195°C; Zone 5 : 200°C; Sixth zone: 195°C; Seventh zone: 190°C; Eighth zone: 185°C; Machine head temperature: 180°C; Screw speed 400r / min, after melt blending extrusion, water cooling, air drying, pelletizing, drying Dry, and finally packaged into bags to obtain anti-drop flame-retardant ABS material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com