Polyolefin resin foaming sheet

A technology of polyolefin resin and foamed sheet, applied in electrical components, printed circuits, etc., can solve problems such as adhesion to glass substrates, and achieve the effect of inhibiting adhesion and promoting easy washing and removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

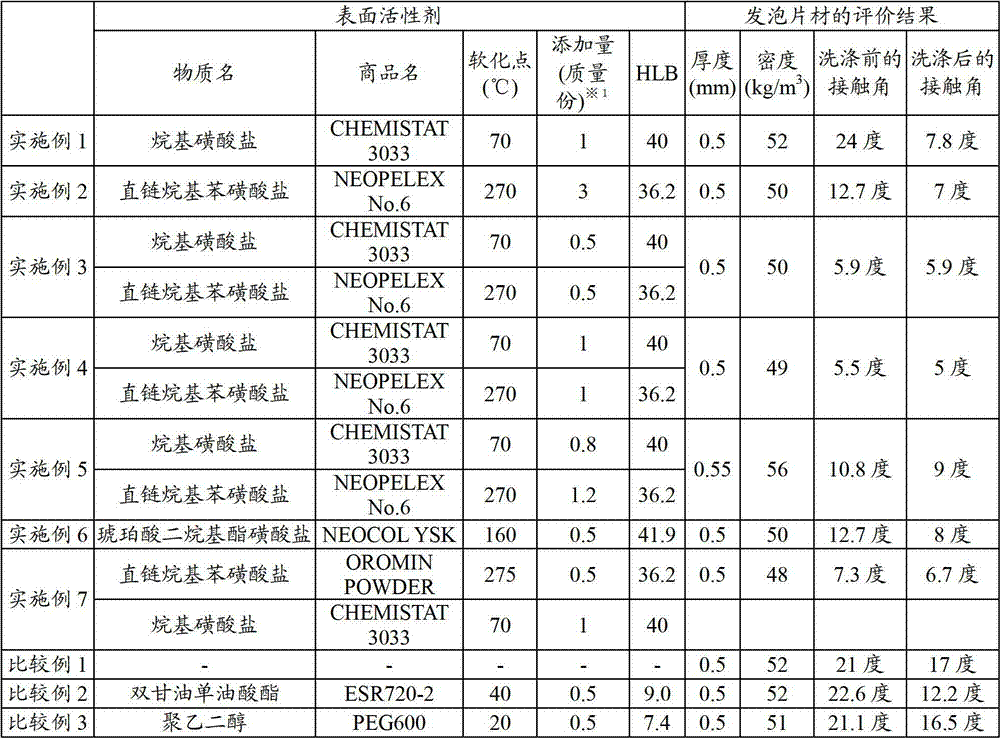

[0095] 100 parts by mass of low density polyethylene resin (trade name: "LF580", density: 929kg / m 3 , MFR=4.0g / 10min) was blended with 7 parts by mass of a polymer antistatic agent manufactured by Sanyo Kasei Co., Ltd. (polyether polypropylene block copolymer, trade name: "PELESTAT 300", crystallization temperature: 85.4°C , MFR=30g / 10 minutes), 1 mass part of anionic surfactant manufactured by Sanyo Chemical Industry Co., Ltd. (containing more than 90 mass% of alkyl sulfonates with 12 to 16 carbon atoms, trade name "CHEMISTAT 3033", Softening point 70°C, hydrophilic-lipophilic balance value 40) and 0.05 parts by mass of a cell regulator masterbatch (azodicarbonamide-containing masterbatch: trade name "CELLMIC MB1023") manufactured by Sankyo Kasei Co., Ltd. The compounded material was supplied to the 1st extruder (barrel diameter: (phi)90mm) of a tandem extruder, and it melt-kneaded so that the maximum attained temperature in this extruder might become 210 degreeC.

[0096] I...

Embodiment 2~5

[0108] The foam seat|seet was produced similarly to Example 1 except having changed the kind and quantity of the anionic surfactant contained in foam seat|seet, and it evaluated similarly to Example 1.

[0109] It should be noted that in Example 2, straight-chain alkylbenzenesulfonate (softening point 270°C, hydrophilic-lipophilic balance value 36.2) manufactured by Kao Corporation was used. The trade name "NEOPELEX No.6" of the main component (containing about 60% by mass of linear alkylbenzene sulfonate, the remainder: sodium sulfate), in Examples 3, 4, and 5, the "NEOPELEX No.6 " was used in combination with "CHEMISTAT 3033" used in Example 1.

Embodiment 6

[0111] In addition to changing the polymer antistatic agent to potassium ionomer manufactured by DU PONT-MITSUI POLYCHEMICALS CO.,LTD. (trade name "ENTIRA AS SD100"), and changing the type and amount of anionic surfactant , The foam seat|seet was produced similarly to Example 1, and it evaluated similarly to Example 1.

[0112] It should be noted that, in Example 6, dialkyl succinate sulfonates such as dioctyl sodium sulfosuccinate manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd. (softening point 160° C., hydrophilic-lipophilic balance value 41.9) The trade name "NEOCOL YSK" which is the main ingredient (approximately 70% by mass active ingredient).

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com