Polystyrene fire retardant material and its preparation method

A technology of polystyrene and fireproof materials, which is applied in the field of building thermal insulation materials, can solve problems such as inability to be flame retardant, and achieve the effect of a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

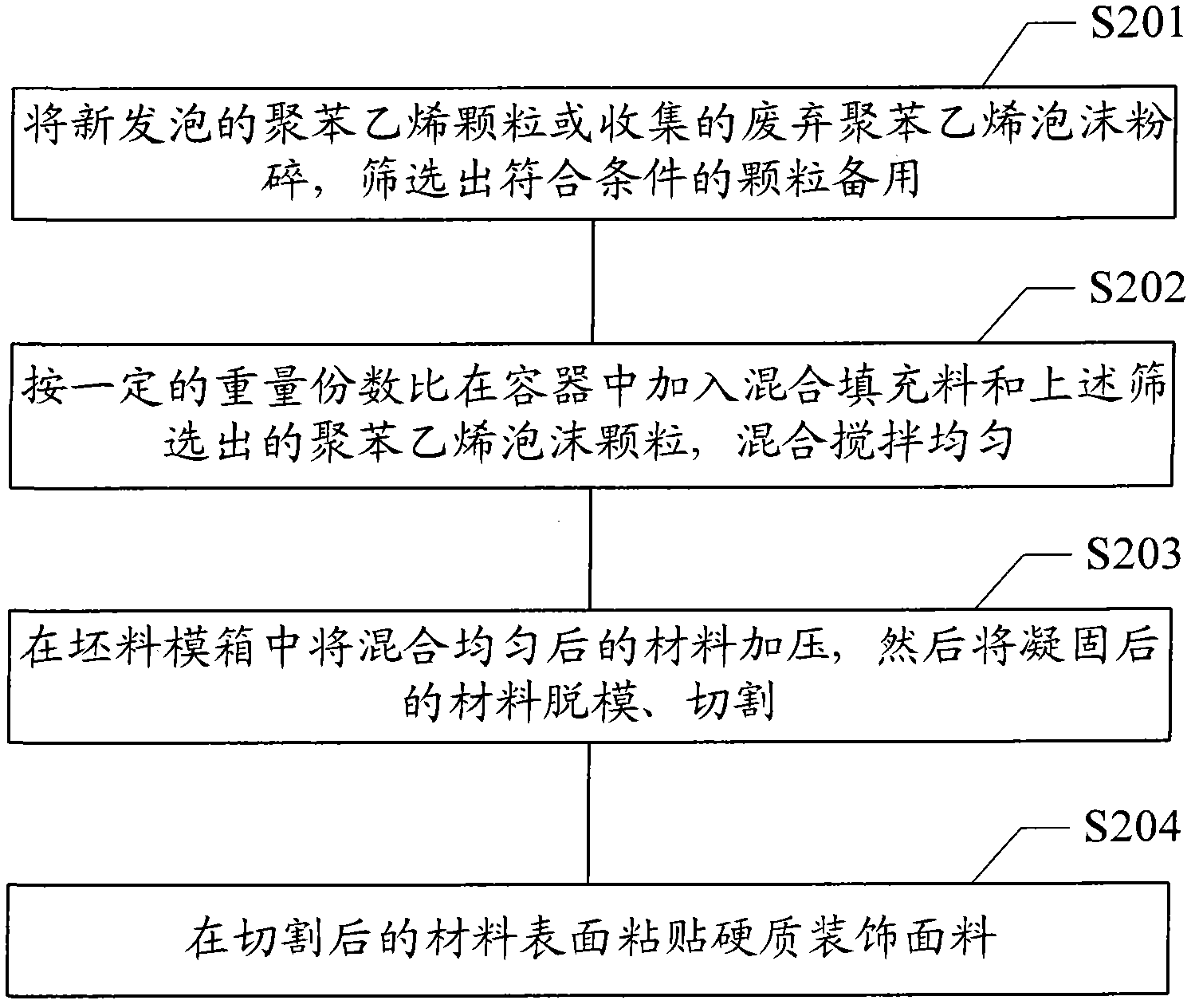

Embodiment 1

[0032] In this preferred embodiment, the mixed filler is composed of rapid hardening cement, water reducer, expansion agent, curing agent, iron oxide, polystyrene special rubber powder and other components, and the iron oxide can catalyze the adsorption of polystyrene particles , Fixing process, so that it does not drift or flow during the solidification process, ensures that the polystyrene particles are wrapped as well as possible by the mixed filler, enhances the isolation effect between polystyrene particles, and fundamentally destroys polystyrene particles under open flame conditions. Polymerization conditions of styrene to achieve the product's fire protection goals. refer to figure 2 , shows the process flow of the first embodiment of the polystyrene fireproof material preparation method of the present invention, specifically including:

[0033] Step S201: Pulverize the newly expanded polystyrene particles or the collected waste polystyrene foam, and select qualified ...

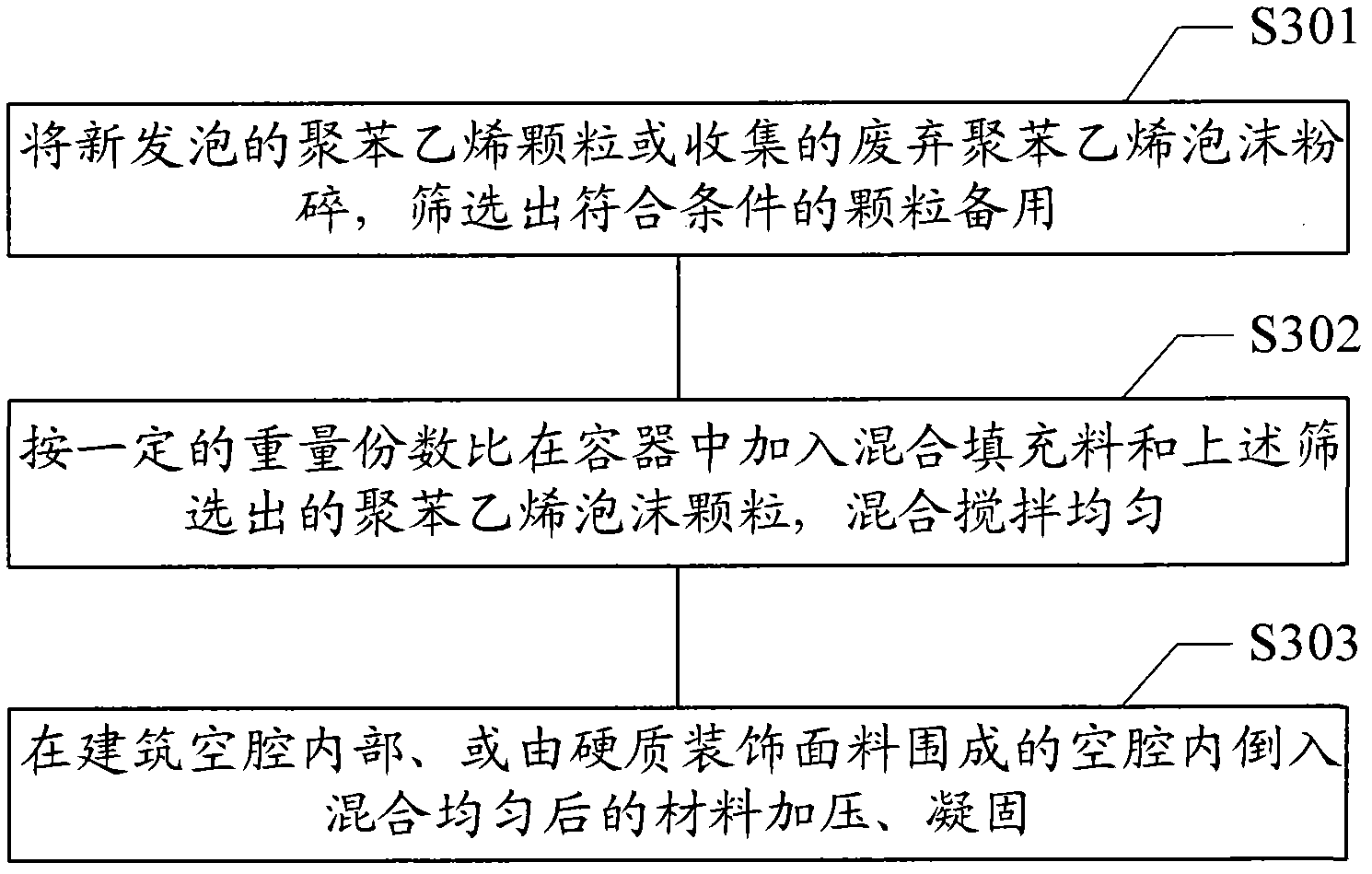

Embodiment 2

[0042] In this preferred embodiment, the homogeneously mixed polystyrene foam material and the mixed filling material are directly poured into the building cavity or the cavity surrounded by hard materials, and are used as insulation materials, which can not only keep polystyrene The characteristics of high strength, light weight, heat insulation, insulation and water resistance can also ensure that polystyrene cannot be melted by direct contact with an open flame under open flame conditions, or even if it melts, it cannot be polymerized to form a flammable glass body. Solve the fire prevention problem of insulation materials. In addition, in order to ensure that the product can also be produced in the northern region in winter, in addition to the ingredients in Method Example 1, the mixed filler is also added with antifreeze, air-entraining agent, defoamer, waterproofing agent, and quick-setting agent. and other ingredients. refer to image 3 , shows the process flow of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com