Method for promoting surface crystallization of glass

A glass surface and glass technology, which is applied in the field of promoting crystallization on the glass surface, can solve the problems of unseen and unsuitable bulk glass, etc., achieve remarkable effects, shorten heat treatment time, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

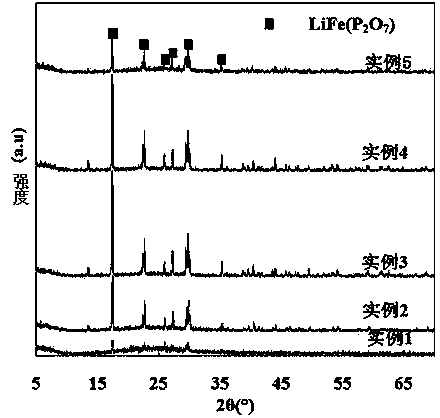

Embodiment 1

[0029] The glass composition is Li 2 O 8%, Fe 2 o 3 29%, P 2 o 5 63%, the preparation method is as follows:

[0030] Weigh the raw materials according to the above mass percentages and mix them evenly, put the mixture into a quartz crucible and melt it in a silicon carbide rod electric furnace at 1200 °C for 1 hour; pour the glass liquid into a preheated mold, and quickly Move it to a muffle furnace that has been heated to 300-400 ° C, keep it warm for 1 hour and anneal. Turn off the muffle furnace and cool down to room temperature. After annealing, the small glass sample was heated at a rate of 5 °C / min to the crystal nucleus formation temperature of 440 °C and kept for 2 hours; then at the same rate of heating to the crystallization peak temperature of 565 °C and kept for 2 hours. After heat treatment, the thickness of the crystallization layer was analyzed by optical microscope, and the thickness of the crystallization layer was 361.6 μm, and the main crystal phase ...

Embodiment 2

[0032] The glass composition is Li 2 O 8%, Fe 2 o 3 29%, P 2 o 5 63%, plus the crystallization promoting agent Cr 2 o 3 5%. The preparation method is as follows:

[0033] Weigh the raw materials according to the above mass percentages and mix them evenly, put the mixed materials into a quartz crucible and melt them in a silicon carbide rod electric furnace at 1200 °C for 1 hour; pour the molten glass into a preheated mold, and quickly Move it to a muffle furnace that has been heated to 300-400 ° C, keep it warm for 1 hour and anneal. Turn off the muffle furnace and cool down to room temperature. After annealing, the small glass sample was heated at a rate of 5 °C / min to the crystal nucleus formation temperature of 490 °C and kept for 2 hours; then at the same rate of heating to the crystallization peak temperature of 620 °C and kept for 2 hours. The thickness of the crystallization layer of the sample after heat treatment was analyzed by optical microscope to be 108...

Embodiment 3

[0035] The glass composition is Li 2 O 8%, Fe 2 o 3 29%, P 2 o 5 63%, plus crystallization promoting agent TiO 2 2%, Cr 2 o 3 3%. The preparation method is as follows:

[0036] Weigh the raw materials according to the above mass percentages and mix them evenly, put the mixed materials into a quartz crucible and melt them in a silicon carbide rod electric furnace at 1200 °C for 1 hour; pour the molten glass into a preheated mold, and quickly Move it to a muffle furnace that has been heated to 300-400 ° C, keep it warm for 1 hour and anneal. Turn off the muffle furnace and cool down to room temperature. After annealing, the small glass sample was heated at a rate of 5 °C / min to the crystal nucleus formation temperature of 480 °C and kept for 2 hours; then at the same rate of heating to the crystallization peak temperature of 620 °C and kept for 2 hours. After heat treatment, the thickness of the crystallization layer was analyzed by optical microscope to be 2047.6 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com