Plasma submerged arc heating method of 5 to 600-ton steel ingot riser

A submerged arc heating and plasma technology, which is applied in the field of plasma submerged arc heating of steel ingot risers of 5 tons to 600 tons, can solve the problems of small influence of surrounding measuring instruments, low power utilization rate, low noise, etc. Improve, improve the yield rate, and promote the effect of floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Trial production of 5.3 tons of steel ingots, pouring molten steel material 42CrMo, pouring molten steel weight 5.3 tons, filling time 17.5min, pouring temperature 1530 ℃.

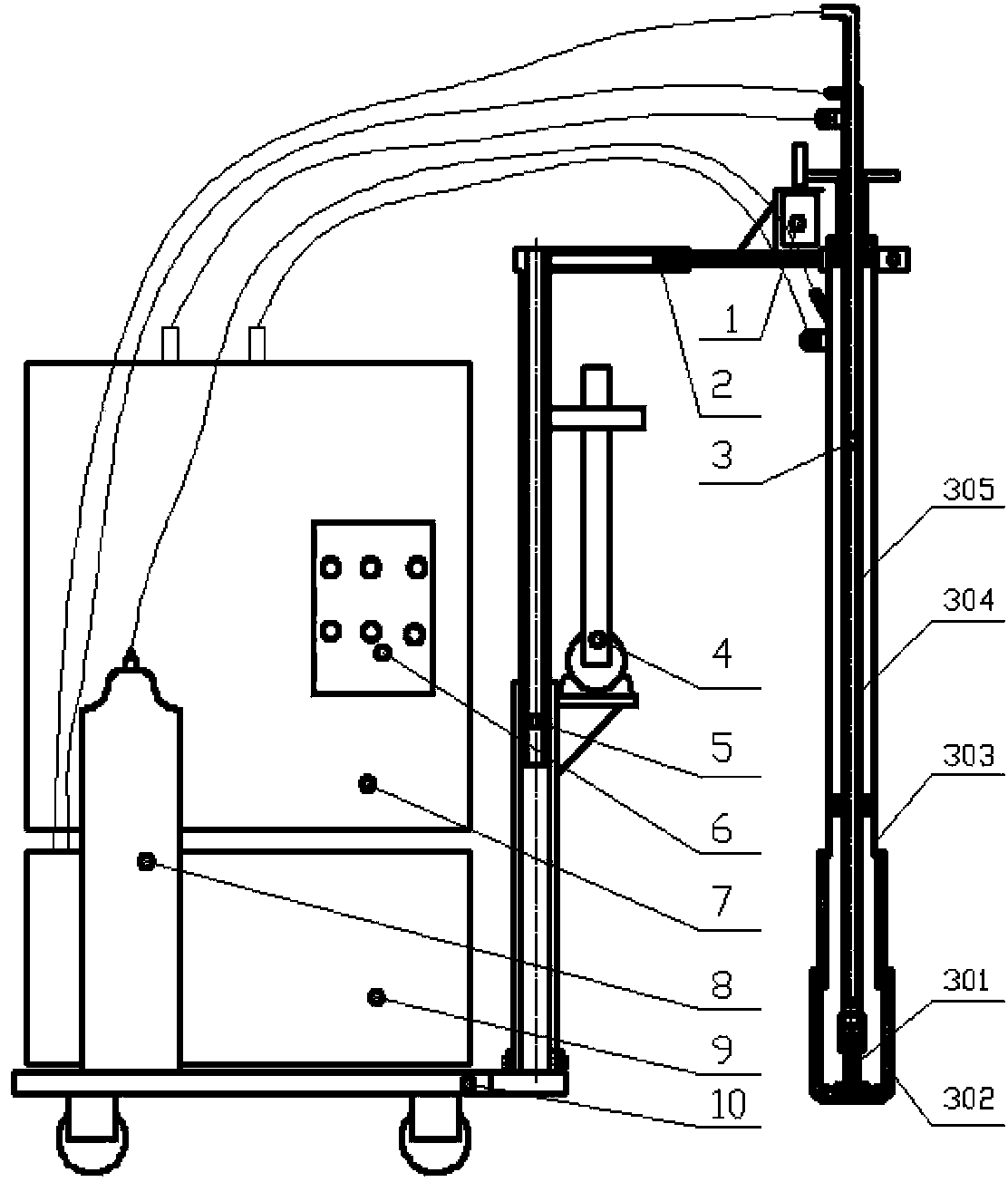

[0065] Such as Figure 8 As shown, in this embodiment, the plasma submerged arc heating method for the steel ingot riser of 5 tons to 600 tons is as follows:

[0066] 1) Strictly control the smelting process, start with the ingredients, select high-quality scrap steel, and reduce the impurity content, P≤0.01wt%, S≤0.01wt%.

[0067] 2) Before the ingot mold is closed, the riser is not preheated.

[0068] 3) During the pouring process, the slow pouring method is adopted, and mold slag is hung at a distance of 300mm from the bottom of the steel ingot.

[0069] 4) 15.5 minutes after the steel ingot is poured, the plasma submerged arc heating gun starts arcing with 5L / min argon gas, and the voltage is 50V; after 2 minutes, the steel ingot is poured and the plasma submerged arc heating gun is preheated....

Embodiment 2

[0072] Trial production of 5.5 tons of steel ingots, pouring molten steel material 42CrMo, pouring molten steel weight 5.8 tons, filling time 18min, pouring temperature 1540 ℃.

[0073] Such as Figure 8 As shown, in this embodiment, the plasma submerged arc heating method for the steel ingot riser of 5 tons to 600 tons is as follows:

[0074] 1) Strictly control the smelting process, start with the ingredients, select high-quality scrap steel, and reduce the impurity content, P≤0.01, S≤0.01.

[0075] 2) Before the ingot mold is closed, the riser is preheated, and the preheating temperature is ≥450°C.

[0076] 3) During the pouring process, the slow pouring method is adopted, the ingot body is poured for 10 minutes, and the riser is poured for 8 minutes.

[0077] 4) 16 minutes after the steel ingot is poured, the plasma submerged arc heating gun starts arcing with 6L / min argon gas, and the voltage is 80V; after 2 minutes, the steel ingot is poured and the plasma submerged ar...

Embodiment 3

[0080] Trial production of 5.5 tons of steel ingots, pouring molten steel material 42CrMo, pouring molten steel weight 5.5 tons, filling time 18min, pouring temperature 1560 ℃.

[0081] Such as Figure 8 As shown, in this embodiment, the plasma submerged arc heating method for the steel ingot riser of 5 tons to 600 tons is as follows:

[0082] 1) Strictly control the smelting process, start with the ingredients, select high-quality scrap steel, and reduce the impurity content, P≤0.02, S≤0.01.

[0083] 2) Before the ingot mold is closed, the riser is not preheated.

[0084] 3) During the pouring process, the slow pouring method is adopted, the ingot body is poured for 10 minutes, and the riser is poured for 8 minutes.

[0085] 4) 16 minutes after the steel ingot is poured, the plasma submerged arc heating gun starts arcing with 7L / min argon gas, and the voltage is 120V; after 2 minutes, the steel ingot is poured and the plasma submerged arc heating gun is preheated. When the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com