Mineral powder gas delivery dry-type magnetic separation device and method

A dry magnetic separation and gas technology, which is used in swirl devices, chemical instruments and methods, and devices whose axial directions of swirl can be reversed, etc. Reduce the sorting effect and other problems to achieve the effect of low cost, lower operating expenses, and higher yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

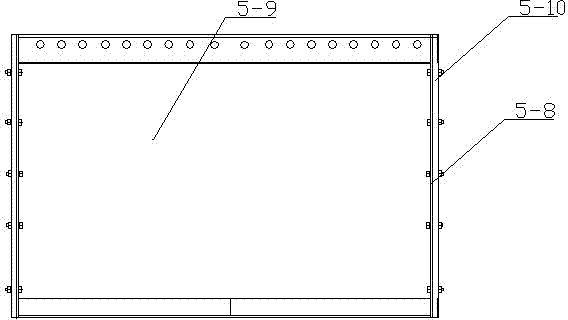

[0038] Depend on figure 1 , figure 2 It can be seen that the mineral powder gas conveying dry magnetic separation device consists of a dry ball mill 1, a rolling screen 2, an ore feeding belt conveyor 3, a feeding hopper 4, a dry magnetic separator 5, a gravity separator 15, a fan 13, and a dust collector. Device 12, forms through pipeline connection.

[0039] The dry magnetic separator is equipped with arc-shaped magnetic separation air ducts 5-4, and the magnetic separation working gap is 40mm. The air volume regulating valve 9 is connected with the pressure air pipe 10, and the opening of the regulating valve can be adjusted to control the air flow entering the negative pressure air pipe. The pressurized air pipe is connected with the air outlet of the fan, and the pressurized air pipe is provided with a shunt pipe 11 to be connected with the dust collector to remove dust in the pipeline system. The arc-shaped magnetic separation air duct is provided with a tailings fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com