Rubber composition and use thereof

A technology of rubber composition and compound, applied in other chemical processes, mechanical equipment, fuel cell parts, etc., can solve the problems of acid resistance, insufficient gas permeability resistance, etc., and achieve excellent gas permeability resistance, Effects of excellent compression set resistance and high-speed formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The preparation method of the copolymer [A] of the present invention is, for example, carried out at a polymerization temperature of 30-60°C (preferably 30-50°C) in the presence of a catalyst containing the following vanadium compound (a) and an organoaluminum compound (b) as main components ℃), the polymerization pressure is 4~12kgf / cm 2 (preferably 5-8kgf / cm 2 ), the molar ratio (non-conjugated polyene / ethylene) of the supply amount of non-conjugated polyene and ethylene is 0.01 to 0.2, and ethylene, α-olefin and the above-mentioned non-conjugated polyene (preferably containing vinyl norbornene compound) copolymerization. The above-mentioned copolymerization reaction is preferably carried out in a hydrocarbon medium.

[0072] Among the vanadium compounds (a), for example, the general formula VO(OR) can be cited a x b or V (OR) c x d (In the formula, R is a hydrocarbon group, 0≤a≤3, 0≤b≤3, 2≤a+b≤3, 0≤c≤4, 0≤d≤4, 3≤c+d≤4) represented vanadium compounds, or their ...

Embodiment

[0129] Hereinafter, the present invention will be more specifically described based on examples, but the present invention is not limited to these examples.

[0130] The compounding components of the rubber composition used in Examples 1-7 and Comparative Examples 1-8 are as follows.

[0131] ・Ethylene・α-Olefin・Non-conjugated polyene copolymer[A]

[0132] For Examples 1 to 7 and Comparative Examples 1 to 8, ethylene·propylene·5-vinyl-2-norbornene random copolymer (ethylene content: 52.7% by mass, propylene content: 42.6% by mass, 5- Vinyl-2-norbornene content: 4.7% by mass, iodine value 25g / 100g, complex viscosity at 25°C (complex viscosity measured using a viscoelasticity measuring device MCR-301 manufactured by Anton Paar Co., Ltd.) (1% deformation) : 1100 Pa·sec, intrinsic viscosity [η] measured in a decahydronaphthalene solution at 135° C.: 0.28 dl / g, “PX-062” manufactured by Mitsui Chemicals Co., Ltd.).

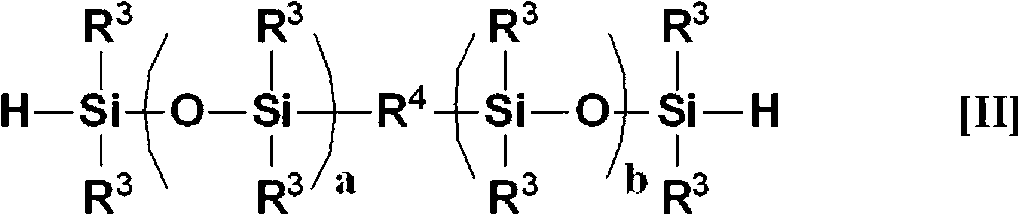

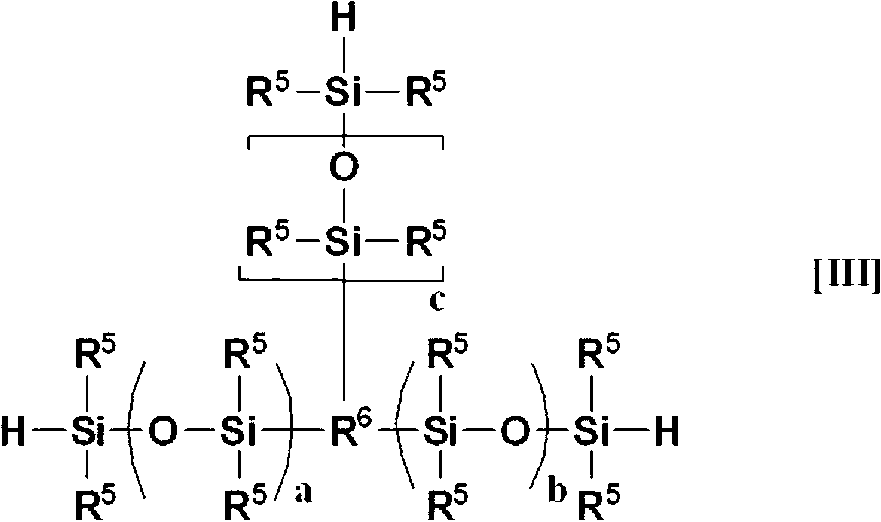

[0133] ・SiH group-containing compound having two SiH groups in on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com