Preparation method of silver colloid for LED (Light Emitting Diode) with high thermal conductivity

A high thermal conductivity, silver glue technology, used in adhesives, epoxy resin glues, conductive adhesives, etc., can solve the problems of difficult processing and complicated operations, and achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

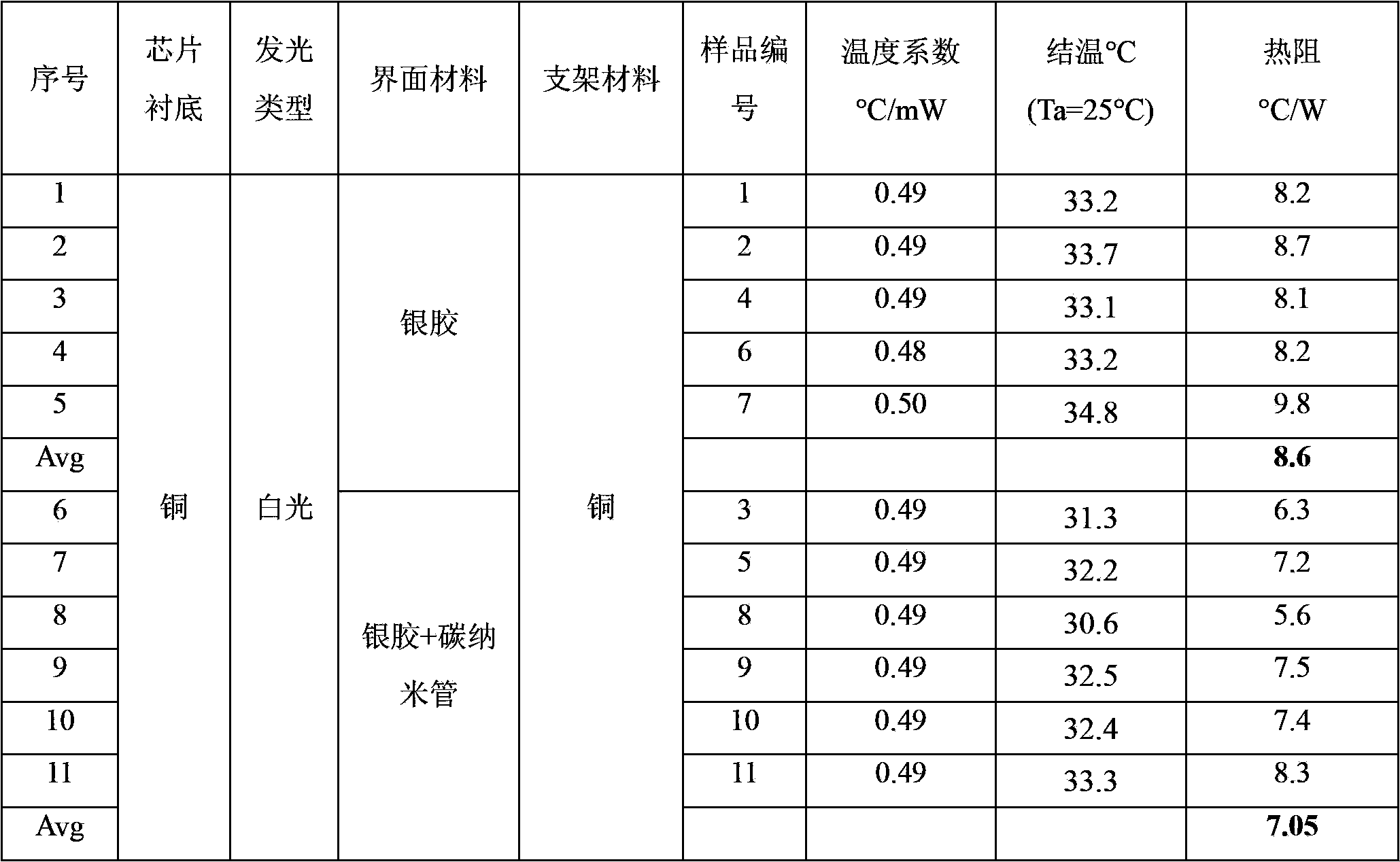

Examples

Embodiment Construction

[0025] The present invention can be further described by the following examples.

[0026] The silver glue is a commercially available LED conductive silver glue.

[0027] The present invention provides a kind of preparation technology of LED silver glue its steps are:

[0028] 1. Put the carbon nanotubes into a ball mill for ball milling, the purpose is to cut and select the length of the carbon nanotubes, and the selected length is 20-30um.

[0029] 2. Soak the carbon nanotubes in concentrated nitric acid for activation treatment, and the treatment time is 10 hours.

[0030] 3. Adding the carbon nanotubes into the ethanol solvent for ultrasonic dispersion, then mixing the suspension containing the carbon nanotubes with the silver colloid and stirring to obtain a mixed solution of the carbon nanotubes and the silver colloid.

[0031] 4. Place the mixture in a flat magnetic field with a magnetic field strength of 10-25 Tesla and let it stand for 10-15 minutes.

[0032] 5. Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com