Polyamide-imide resin insulating coating material, insulated wire and coil

A polyamide-imide resin and insulating coating technology, which is applied in the direction of insulating cables, coils, transformers/inductor coils/windings/connections, etc., can solve the problems of easy partial discharge and high dielectric constant, and achieve coating operations Excellent performance and cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] The polyamide-imide resin insulating varnish of this embodiment can form an insulating coating of an insulated wire by coating and firing on a conductor such as copper or another coating on a conductor.

[0037] As the conductor of the insulated wire, conductors of various shapes such as round wires and flat (square) wires can be used. In addition, another coating such as an adhesive layer for improving adhesion may be used on the upper and lower sides of the insulating coating, and a self-lubricating layer or a self-welding layer may be provided on the insulating coating.

[0038] In addition, the polyamide-imide resin insulating paint can form an insulating coating even when it is applied and baked on members other than wires, such as films and substrates.

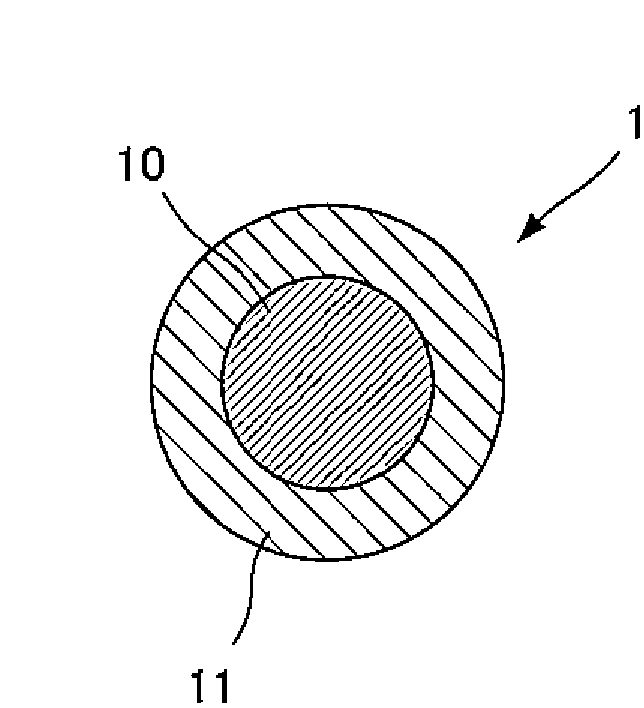

[0039] figure 1 An example of the cross section of the insulated wire according to the embodiment is shown. The insulated wire 1 of the present embodiment has a conductor 10 and an insulating coating 11 covering...

Embodiment 1

[0082] First, prepare a flask equipped with a stirrer, a nitrogen inflow tube, a thermometer, a condenser tube, and a quantitative receiver for moisture, and put 37.3 g of 4-aminobenzoic acid and 1,2,3,6-tetrahydrophthalic anhydride into the flask. 41.3 g was dissolved in 300 g of N-methyl-2-pyrrolidone together with 30 g of xylene as an azeotropic solvent. Then, the solution was stirred at 180° C., and the generated water and xylene were removed from the system to obtain a reaction liquid containing a carboxylic acid compound as an embodiment of the carboxylic acid compound (D).

[0083] Next, after cooling the reaction solution to 60°C, 40.8 g of 4,4'-diphenylmethane diisocyanate, which is the diisocyanate component (E) of the embodiment, was put into the flask, stirred at 130°C for 1 hour, and further After stirring at 140°C for 1.5 hours, an amide compound having a reactive terminal group was synthesized.

[0084] In addition, in another flask, 502.1 g of 2,2-bis(4-aminop...

Embodiment 2

[0087] First, in a flask, 33.6 g of 4-aminobenzoic acid, 37.2 g of 1,2,3,6-tetrahydrophthalic anhydride, and 30 g of xylene as an azeotropic solvent were dissolved in N-methyl-2 - pyrrolidone 300 g. Then, the solution was stirred at 180° C., and the generated water and xylene were removed from the system to obtain a reaction liquid containing a carboxylic acid compound as an embodiment of the carboxylic acid compound (D).

[0088] Next, after cooling the reaction solution to 60°C, 128.6 g of 4,4'-diphenylmethane diisocyanate as the diisocyanate component (E) of the embodiment and 70.5 g of trimellitic anhydride as the tricarboxylic anhydride were mixed with N-methyl - 327.2 g of 2-pyrrolidone was put into a flask together, stirred at 130° C. for 1 hour, and further stirred at 140° C. for 1.5 hours to synthesize an amide compound having a reactive terminal group.

[0089] In addition, in another flask, 451.9 g of 2,2-bis(4-aminophenoxyphenyl)propane as the diamine component (A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com