Novel polymer proton exchange membrane and preparation method thereof

A proton and exchange membrane technology, which is applied in the field of proton exchange membrane preparation for new direct methanol fuel cells, can solve the problems of cumbersome synthesis process conditions of crosslinking agents, etc., and achieve good proton conductivity, thermal stability and tensile strength improvement , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

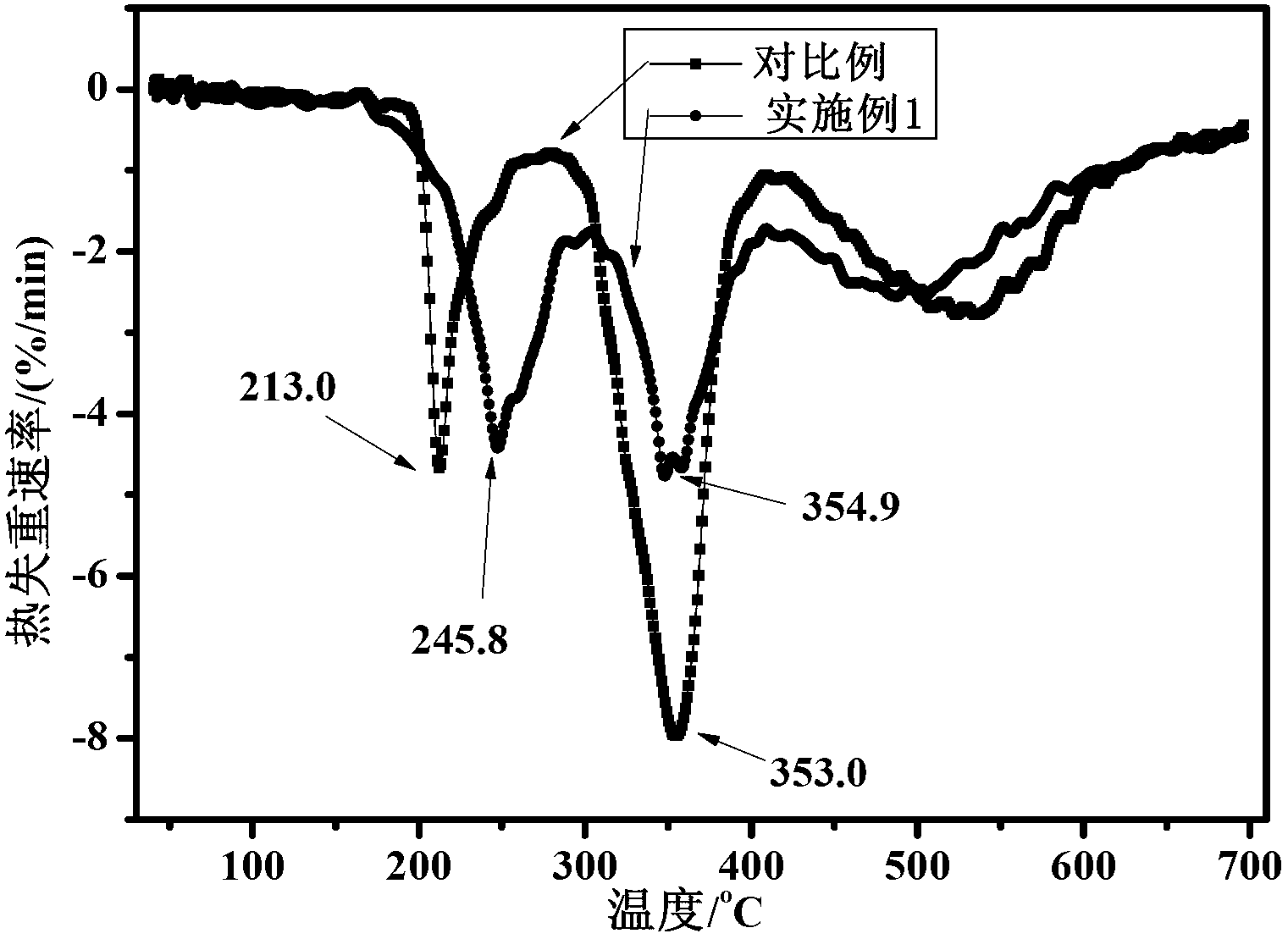

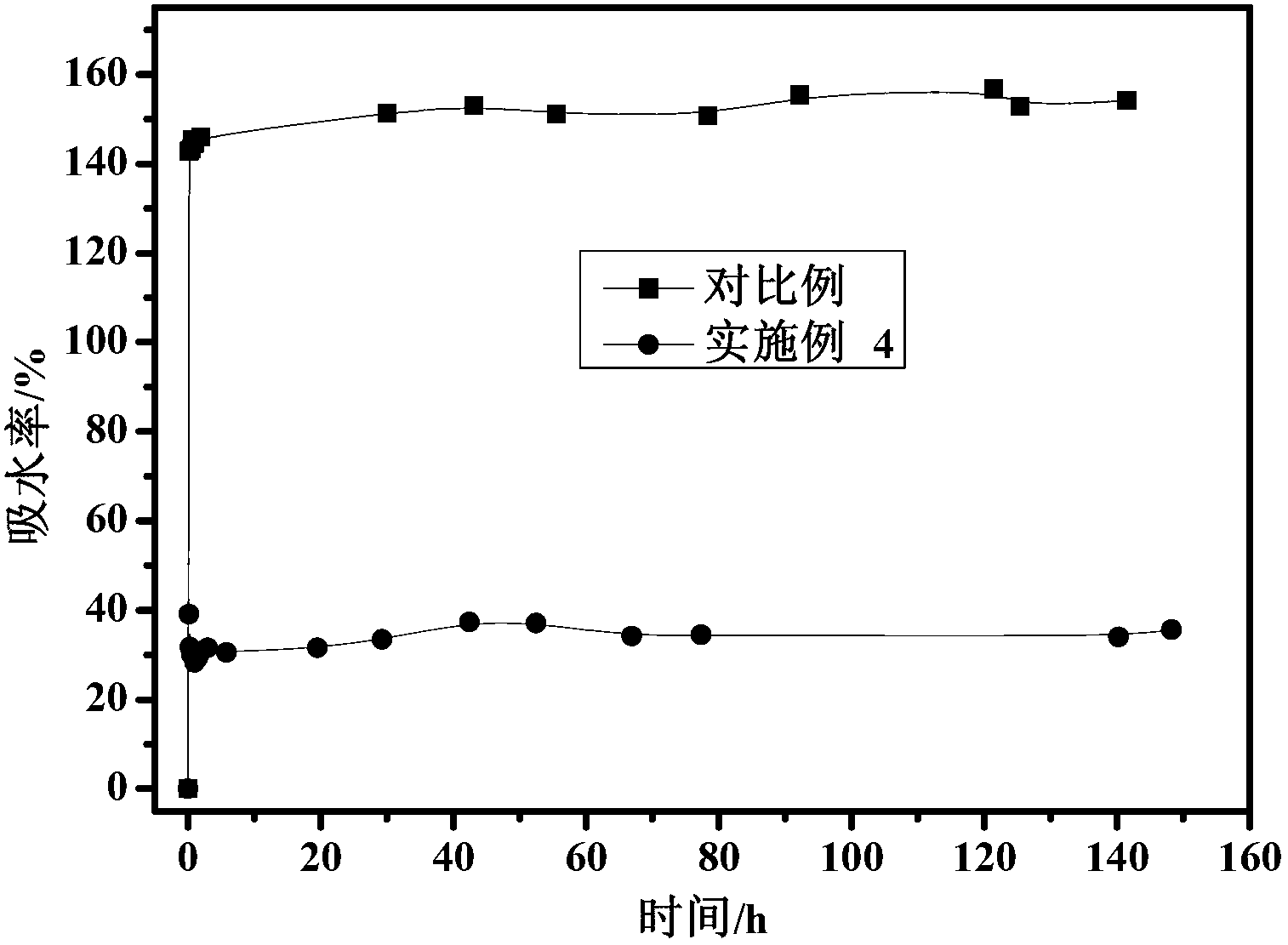

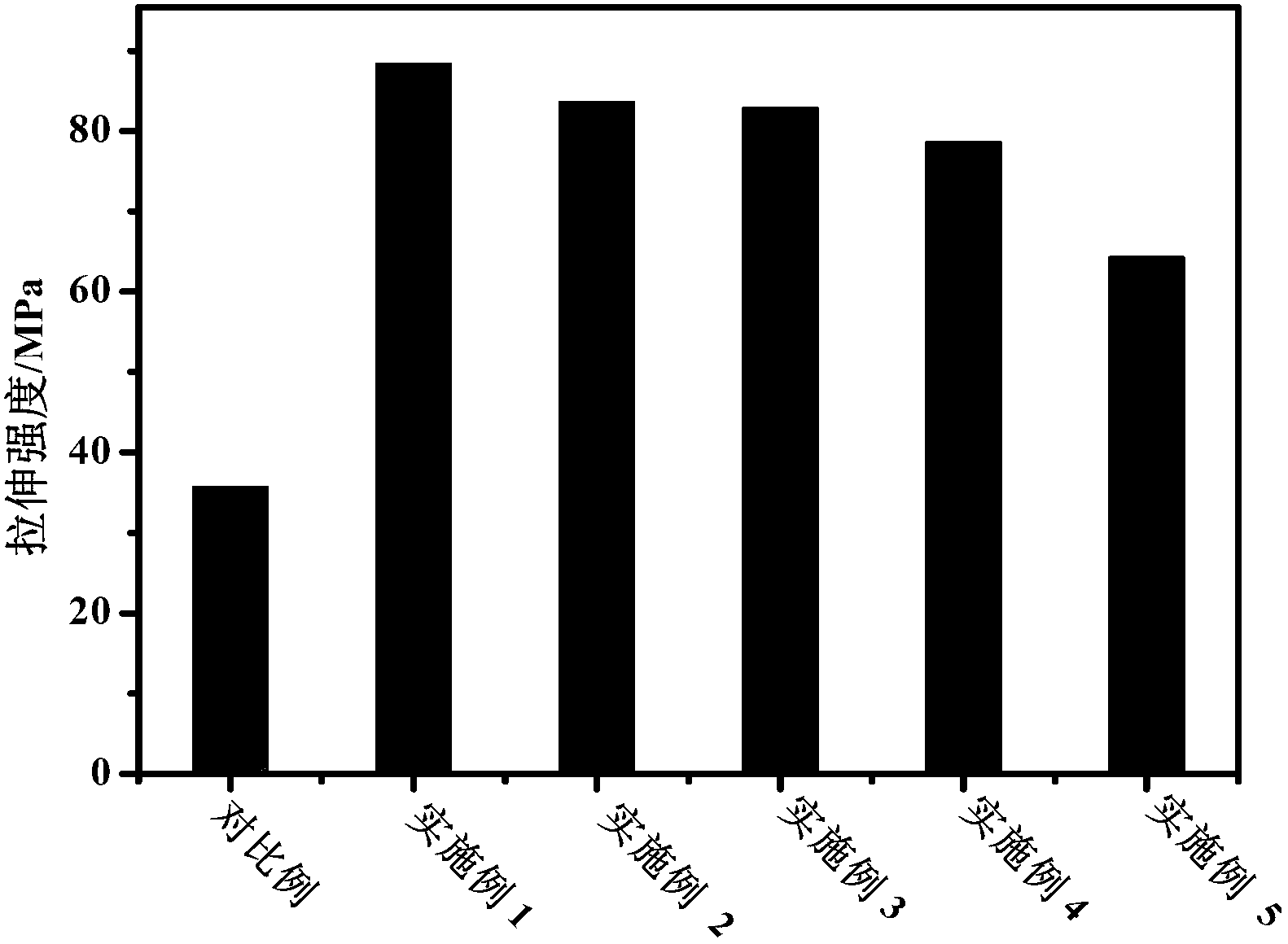

Embodiment 1

[0039] Dissolve 100 parts of sulfonated polyether ether ketone with a degree of sulfonation of 80% in 100 parts of N,N-dimethylacetamide. After the sulfonated polyether ether ketone is completely dissolved, add 5 parts of styrene and 1 part of dimethicone. Vinylbenzene, stirring at a speed of 150 rpm, to make the reaction solution evenly mixed; the temperature was raised to 65 ° C, and after the temperature was constant, 0.5 part of azodiethylheptonitrile was dissolved in 10 parts of N,N-dimethylacetamide, and added instantly In the reaction solution, the constant temperature and constant speed reaction was continued for 5h; after the reaction was completed, the temperature was lowered, the reaction solution was poured into the mold, and the solvent was removed to obtain a sulfonated polyetheretherketone / polystyrene-divinylbenzene polymerization with a semi-interpenetrating network structure Substance exchange membrane. The semi-interpenetrating network polymer proton exchange...

Embodiment 2

[0041] Dissolve 100 parts of sulfonated polyether ether ketone with a sulfonation degree of 55% in 300 parts of N-methylpyrrolidone, after the sulfonated polyether ether ketone is completely dissolved, add 15 parts of styrene and 10 parts of divinylbenzene, Stir the reaction solution at a stirring speed of 700 rpm to make the reaction solution evenly mixed; the temperature is raised to 85°C and after the temperature is constant, 1 part of benzoyl peroxide is dissolved in 15 parts of N-methylpyrrolidone, and added dropwise to the reaction solution within 0.5h . After the initiator solution was added dropwise, the reaction was continued at constant temperature and constant speed for 5 hours, the temperature was lowered, the reaction solution was poured into the mold, and the solvent was removed to obtain a sulfonated polyetheretherketone / polystyrene-divinylbenzene with a semi-interpenetrating network structure Polymer proton exchange membrane. The semi-interpenetrating network ...

Embodiment 3

[0043] Dissolve 100 parts of sulfonated polyether ether ketone with a sulfonation degree of 30% in 500 parts of dimethyl sulfoxide. After the sulfonated polyether ether ketone is completely dissolved, add 20 parts of styrene and 2 parts of divinylbenzene, Stir the reaction liquid at a stirring speed of 400 rpm, and mix the reaction liquid evenly; the temperature is raised to 80 ° C, and after the temperature is constant, 2 parts of dimethyl azobisisobutyrate are dissolved in 20 parts of dimethyl sulfoxide, and added dropwise within 0.5 h into the reaction solution. After the initiator solution was added dropwise, the reaction was continued at a constant temperature and constant speed for 2 hours, then the temperature was lowered, the reaction solution was poured into the mold, and the solvent was removed to obtain a sulfonated polyetheretherketone / polystyrene-divinylbenzene with a semi-interpenetrating network structure Polymer proton exchange membrane. The semi-interpenetrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com