Composite expandable flame retardant modified thermosetting resin and preparation method thereof

An intumescent flame retardant and composite technology, which is applied in the field of composite intumescent flame retardant modified thermosetting resin and its preparation, can solve the problem of difficult dispersibility, interfacial force, reduction of material heat resistance, influence on flame retardant performance, etc. problems, to achieve excellent thermal oxygen shielding effect, good bonding force, outstanding heat resistance and flame retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

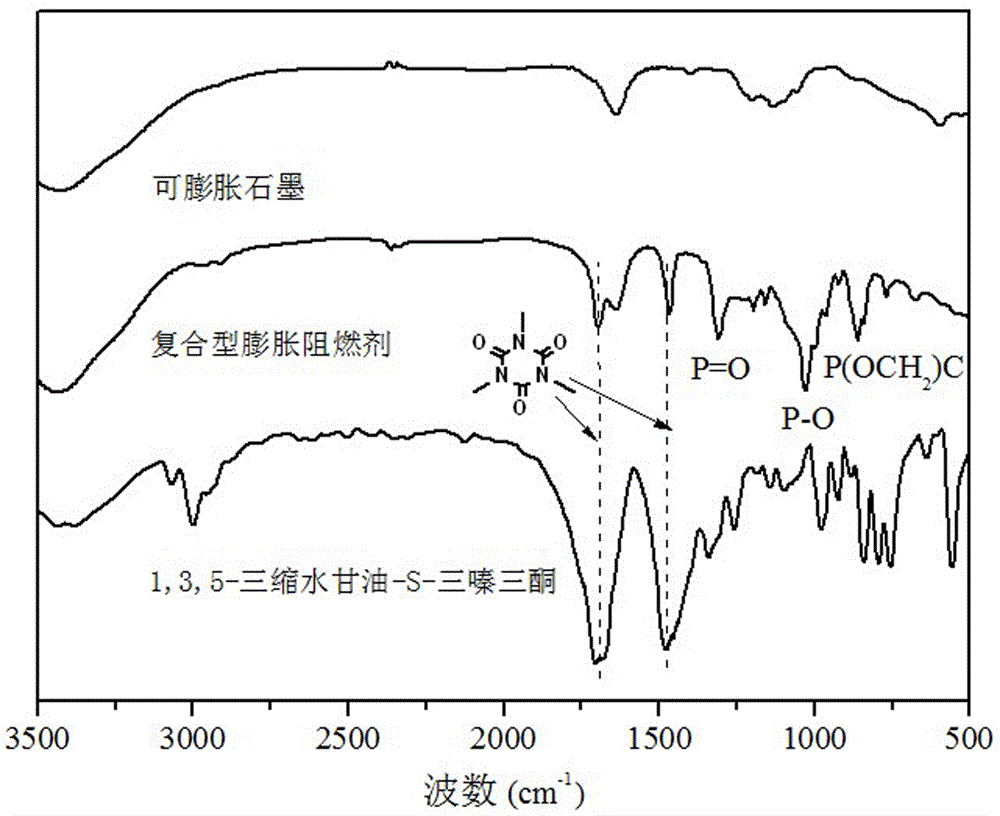

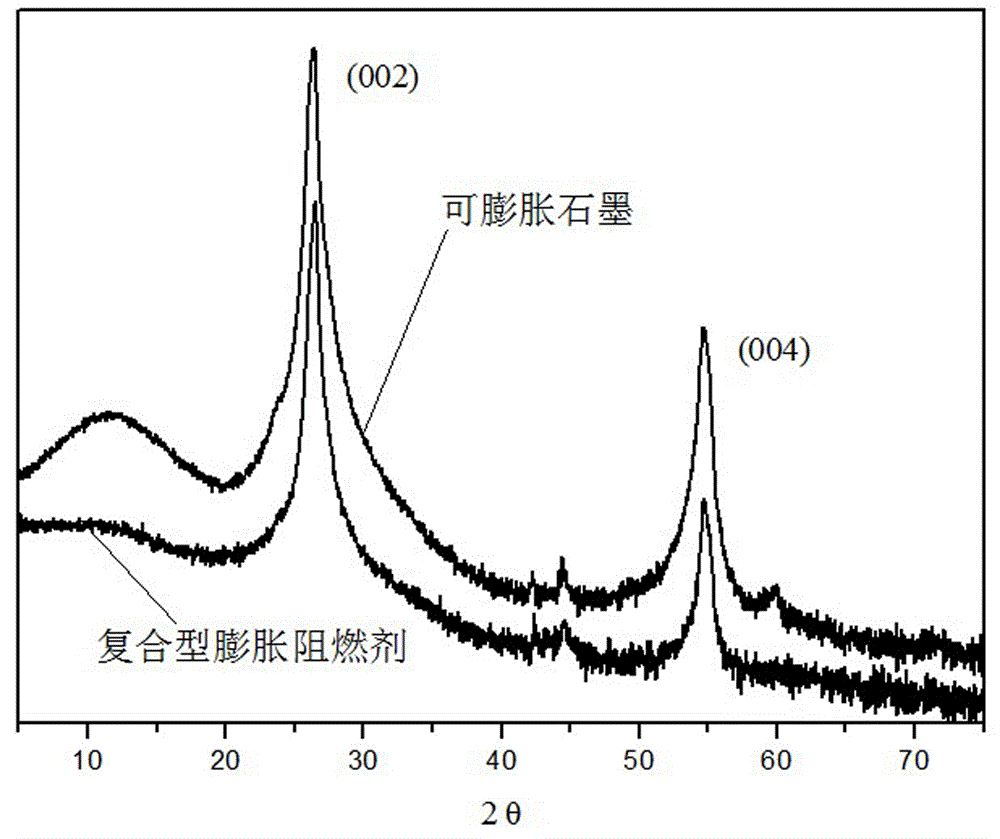

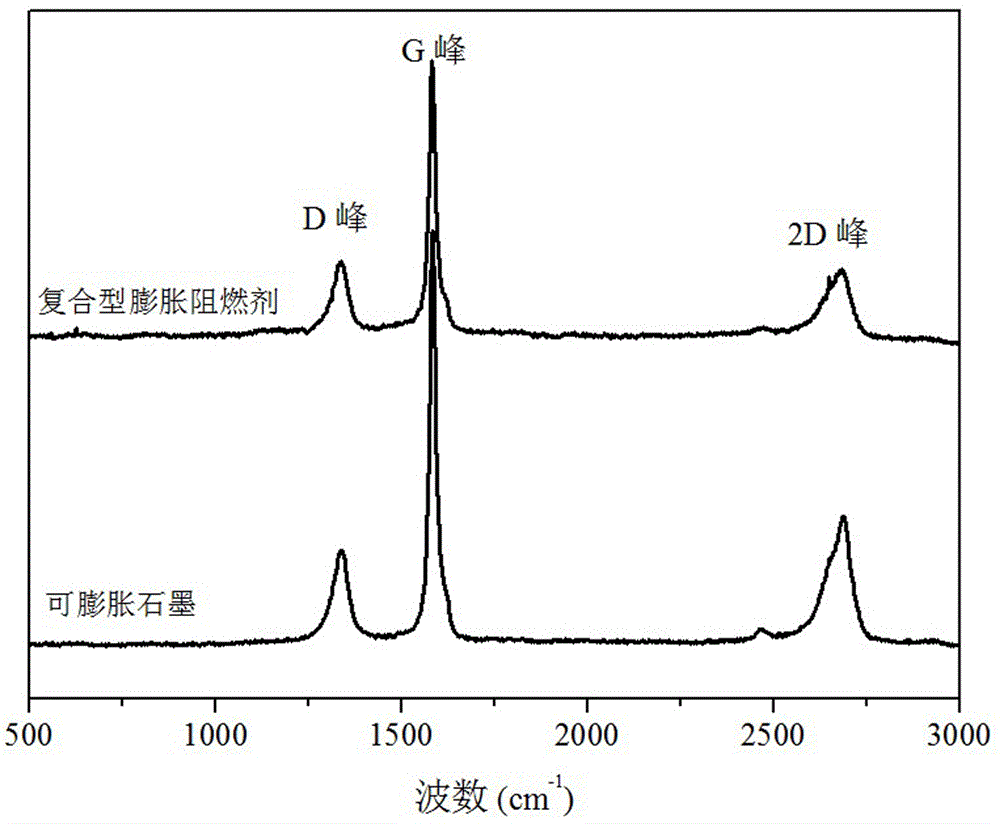

[0026] 1. Preparation of composite intumescent flame retardant

[0027] Add 5g of 80 mesh expandable graphite and 50g of dioxane into a three-necked flask, stir and mix evenly to obtain a suspension A of expandable graphite;

[0028] Add 2.58g of phosphorus oxychloride to 25.8g of dioxane to prepare solution B. Add solution B to suspension A to obtain mixed solution C; heat mixed solution C to 40°C, and react under nitrogen protection for 2 hours to obtain reaction solution D in which phosphorus oxychloride expandable graphite is formed;

[0029] According to the molar ratio of phosphorus oxychloride and pentaerythritol as 1:1, 2.29g of pentaerythritol was added to the above reaction solution D, and 0.0046g of anhydrous stannous chloride was added; the temperature was raised to 60°C for 4 hours to obtain reaction solution E. According to the pentaerythritol and 1,3,5-triglycidyl-S-triazinetrione molar ratio of 1:1, 5.63g of 1,3,5-triglycidyl-S-triazinetrione was added to the ...

Embodiment 2

[0038] 1. Preparation of composite intumescent flame retardant

[0039] Add 5g of 100 mesh expandable graphite and 50g of dioxane into a three-necked flask, stir and mix evenly to obtain a suspension A of expandable graphite;

[0040] Add 2 g of phosphorus oxychloride to 20 g of dioxane to prepare solution B. Add solution B to suspension A to obtain mixed solution C; heat mixed solution C to 50° C., and react under nitrogen protection for 1 hour to obtain reaction solution D in which phosphorus oxychloride expandable graphite is formed;

[0041] According to the molar ratio of phosphorus oxychloride and pentaerythritol as 1:1, 1.03g of pentaerythritol was added to the above reaction solution D, and 0.0021g of anhydrous stannous chloride was added; the temperature was raised to 70°C for 3 hours to obtain reaction solution E. According to the pentaerythritol and 1,3,5-triglycidyl-S-triazinetrione molar ratio of 1:1.5, 5.82g of 1,3,5-triglycidyl-S-triazinetrione was added to the...

Embodiment 3

[0047] 1. Preparation of composite intumescent flame retardant

[0048] Composite intumescent flame retardant was prepared according to Example 2.

[0049] 2. Preparation of composite intumescent flame retardant modified cyanate resin and its cured product

[0050] Weigh 10g of composite intumescent flame retardant and 90g of bisphenol A cyanate, stir and mix them at 80°C to obtain a composite intumescent flame retardant-modified cyanate resin.

[0051] Pour the obtained composite intumescent flame retardant modified cyanate ester resin into a preheated mold, and vacuum defoam at 150°C for 1 hour. o C / 2h+200 o C / 2h+220 o The process of C / 2h is solidified, and after natural cooling, the mold is demoulded, and the solidified composite intumescent flame retardant modified cyanate ester resin is obtained. Typical properties of the cured resins are shown in the attached Figure 5 , 6 and 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com