Sand adhering prevention cast steel EPC (Expendable Pattern Casting) coating and preparation method thereof

A technology of lost foam and anti-sticking sand, applied in casting molding equipment, coating, mold and other directions, can solve the problems of quality degradation of castings, difficulty in preventing the penetration of high-temperature molten steel, decrease in air permeability, etc., and achieve the effect of simplification and peeling of subsequent processing. Outstanding and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

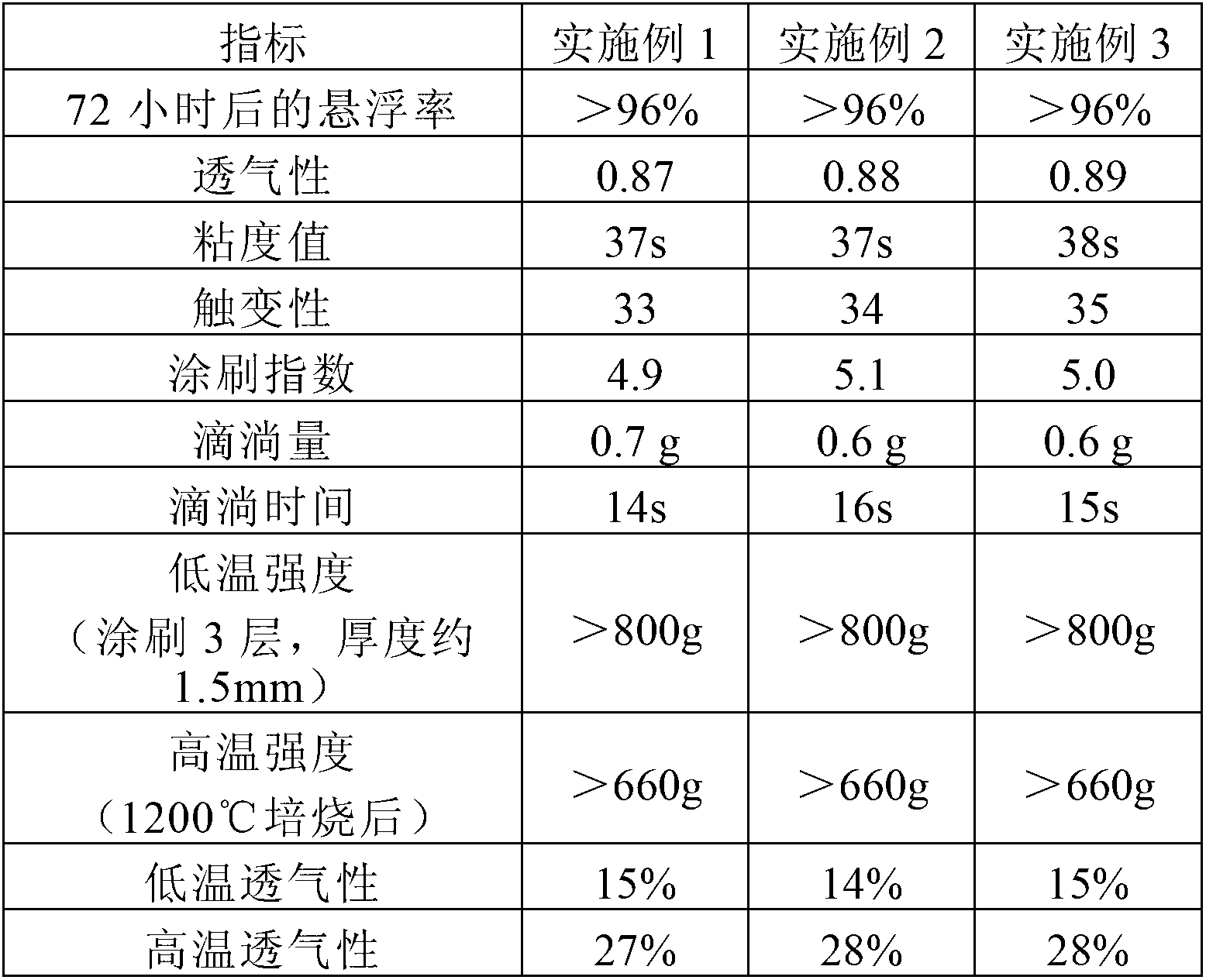

Examples

Embodiment 1

[0028] Anti-stick sand cast steel lost foam coating, comprising the following components: 15 parts by weight of high alumina bauxite clinker, 12 parts by weight of graphite powder, 3 parts by weight of bentonite, 0.5 part by weight of water glass, and 2.25 parts by weight of sodium carboxymethyl cellulose , 0.45 parts by weight of n-octanol, and 0.45 parts by weight of fatty alcohol polyoxyethylene ether.

[0029] The above-mentioned anti-stick sand cast steel lost foam coating is prepared by the following method:

[0030] First, add 30 parts by weight of water to 3 parts by weight of bentonite, and stir at a high speed for 5 hours to form a bentonite slurry;

[0031] At the same time, 15 parts by weight of high alumina bauxite clinker and 12 parts by weight of graphite powder were stirred evenly in the grinding equipment to obtain aggregate, and then 15 parts by weight of water was added to make the aggregate wet and stirred;

[0032] Then add 0.5 parts by weight of water gl...

Embodiment 2

[0035] Anti-stick sand cast steel lost foam coating, contains the following components:

[0036] 45 parts by weight of high alumina bauxite clinker, 36 parts by weight of graphite powder, 1 part by weight of bentonite, 1.5 part by weight of water glass, 0.75 part by weight of sodium carboxymethyl cellulose, 0.15 part by weight of n-octanol, fatty alcohol polyoxyethylene ether 0.15 parts by weight.

[0037] The above-mentioned anti-stick sand cast steel lost foam coating is prepared by the following method:

[0038] First, add 10 parts by weight of water to 1 part by weight of bentonite, and stir at a high speed for 7 hours to form a bentonite slurry;

[0039] At the same time, 45 parts by weight of high alumina bauxite clinker and 36 parts by weight of graphite powder were stirred evenly in the grinding equipment to obtain aggregate, and then 45 parts by weight of water was added to make the aggregate wet and stirred;

[0040] Then add 1.5 parts by weight of water glass, 0.7...

Embodiment 3

[0043] Anti-stick sand cast steel lost foam coating, comprising the following components: 30 parts by weight of high alumina bauxite clinker, 25 parts by weight of flake graphite powder, 2 parts by weight of bentonite, 1 part by weight of water glass, and 1.5 parts by weight of sodium carboxymethyl cellulose parts by weight, 0.3 part by weight of n-octanol, and 0.3 part by weight of fatty alcohol polyoxyethylene ether.

[0044] The above-mentioned anti-stick sand cast steel lost foam coating is prepared by the following method:

[0045] First, add 20 parts by weight of water to 2 parts by weight of bentonite, and stir at a high speed for 6 hours to form a bentonite slurry;

[0046] At the same time, 30 parts by weight of high alumina bauxite clinker and 25 parts by weight of flake graphite powder were stirred evenly in the grinding equipment to obtain aggregate, and then 30 parts by weight of water was added to make the aggregate wet and stirred;

[0047] Then add 1 weight pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com