Electrolyte with high flame retardation performance and electrochemical performance and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of degraded battery electrochemical performance, electrochemical performance damage, low flame retardant efficiency, etc., and achieve excellent battery performance, overcome impact, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

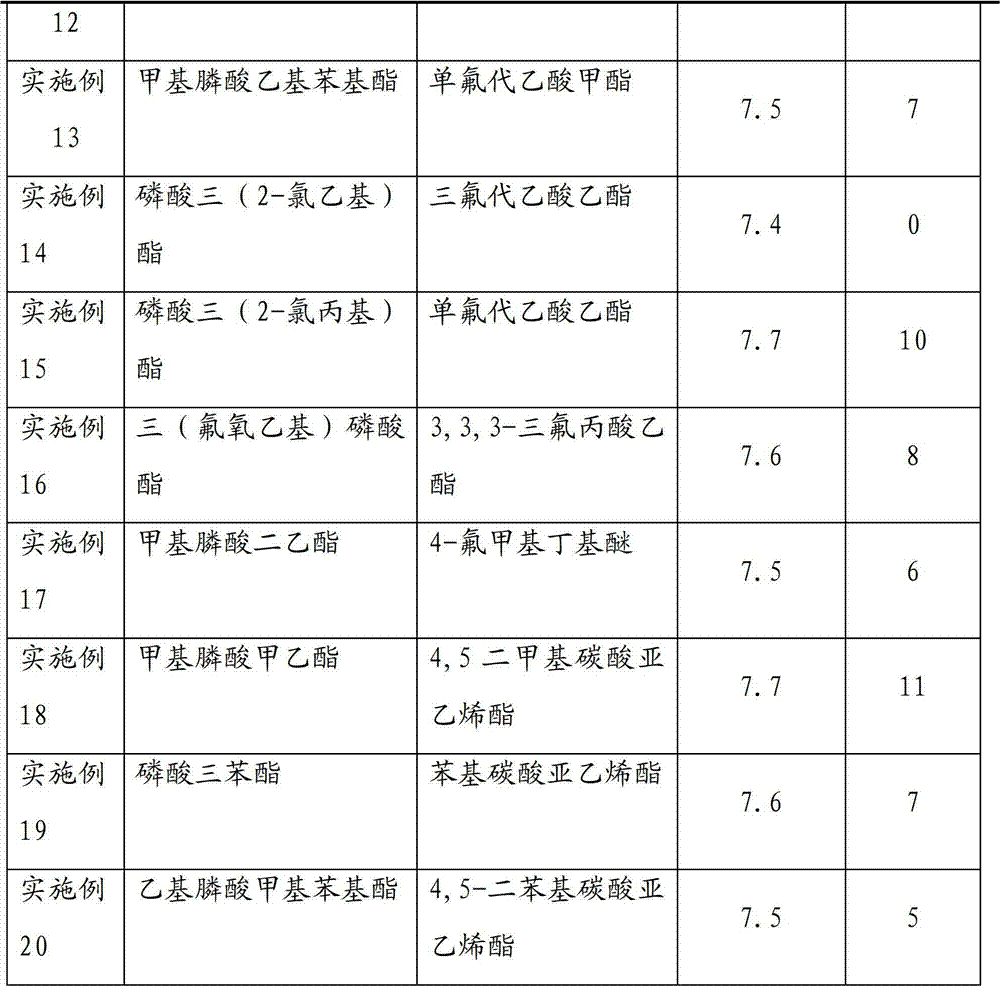

Examples

Embodiment 1

[0063] An electrolyte solution for a lithium-ion battery with high flame retardancy and electrochemical performance described in this embodiment, the electrolyte comprises a solvent (EC+DEC (1:2 mass ratio), a lithium salt (Li PF 6 ), a flame retardant and an additive, the amount of the lithium salt is 1mol / L, the amount of the flame retardant dimethyl phosphonate accounts for 10% of the total mass of the electrolyte, and the additive difluoropropylene carbonate The amount of ester accounts for 5% of the total mass of the electrolyte.

[0064] Lithium-ion batteries were prepared using the above electrolytic solutions by conventional methods.

Embodiment 2

[0066] A lithium-ion battery electrolyte with high flame retardancy and electrochemical performance described in this embodiment, the electrolyte includes a solvent (EC+DEC (1:2 mass ratio), lithium salt (LiPF 6 ), a flame retardant and an additive, the amount of the lithium salt is 1mol / L, the amount of the flame retardant dimethyl ethyl phosphate accounts for 15% of the total mass of the electrolyte, and the additive difluoroethylene carbonate The amount of ester accounts for 4% of the total mass of the electrolyte.

[0067] Lithium-ion batteries were prepared using the above electrolytic solutions by conventional methods.

Embodiment 3

[0069] A lithium-ion battery electrolyte with high flame retardancy and electrochemical performance described in this embodiment, the electrolyte includes a solvent (EC+DEC (1:2 mass ratio), lithium salt (LiPF 6 ), a flame retardant and an additive, the amount of the lithium salt is 0.8mol / L, the amount of the flame retardant tributyl phosphate accounts for 20% of the total mass of the electrolyte, and the additive methyl monofluoroacetate The dosage accounts for 10% of the total mass of the electrolyte.

[0070] Lithium-ion batteries were prepared using the above electrolytic solutions by conventional methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com