Method for strengthening thin film in flexible thin film transistor manufacturing process

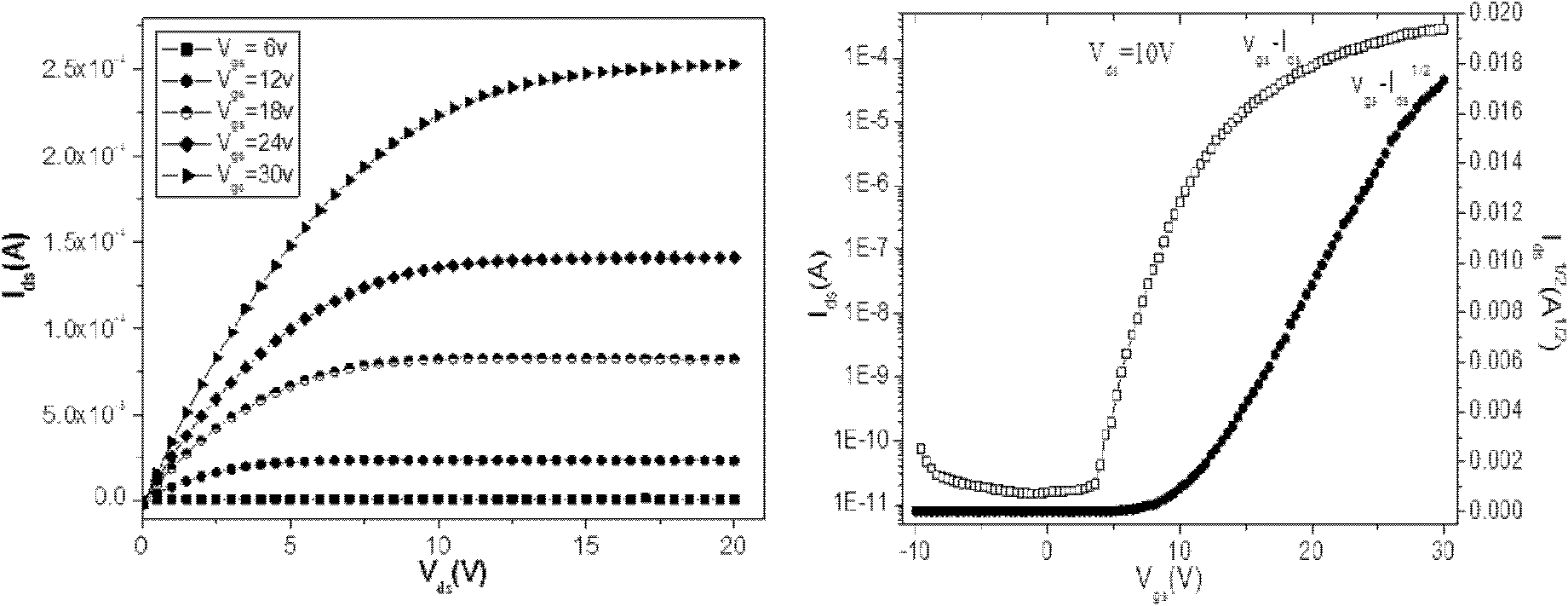

A flexible thin film and transistor technology, applied in the field of microelectronics, can solve the problems of film cracking, peeling off, and no IGZO-TFT electrical performance curve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The method for preparing a process-enhanced thin film for a flexible thin film transistor provided by the present invention will be described in detail below with reference to the accompanying drawings and specific examples.

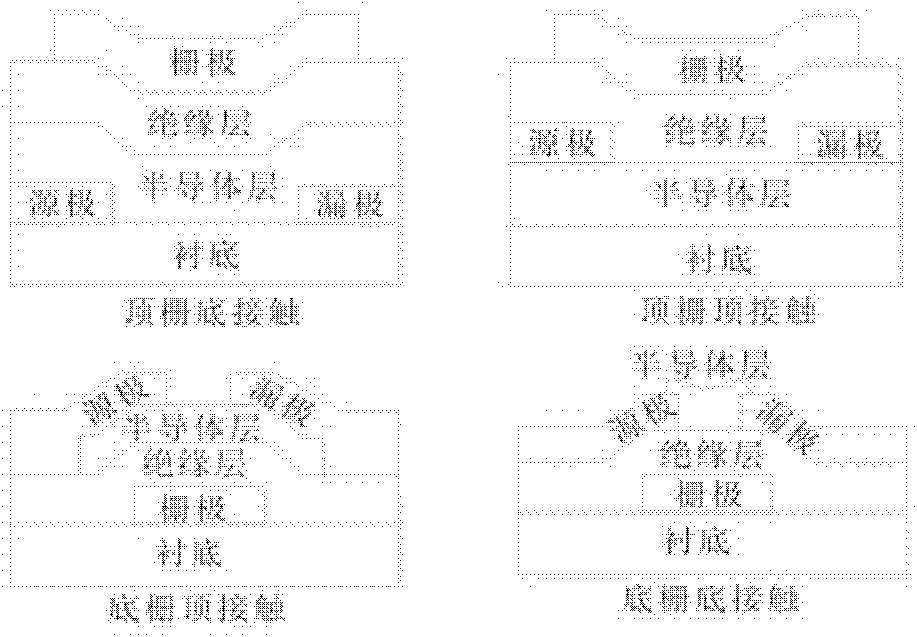

[0019] Fabrication of thin film layer of flexible IGZO-TFT device structure

[0020] Substrate Material Selection

[0021] The plastic substrate material of Dupont Company is selected, the model is Kapton E, and the specifications are 50 μm and 25 μm respectively, the former is used to prepare flexible devices, and the latter is used to explore the preparation of flexible transparent devices. It has a higher glass transition temperature (Tg=340°C), a lower thermal expansion coefficient (when the temperature is in the range of 50°C-200°C, the thermal expansion coefficient is 16ppm / °C), better chemical stability (unlike The solution in the prepared TFT reacts), good waterproof performance (for a 50μm thick Kapton E substrate, the water vapor permea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Deposition thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com